IACMI officially opens new innovation facility in Detroit

Two years in the works, the IACMI Vehicles Scale-Up Facility offers the automotive industry a composite materials and manufacturing development innovation center.

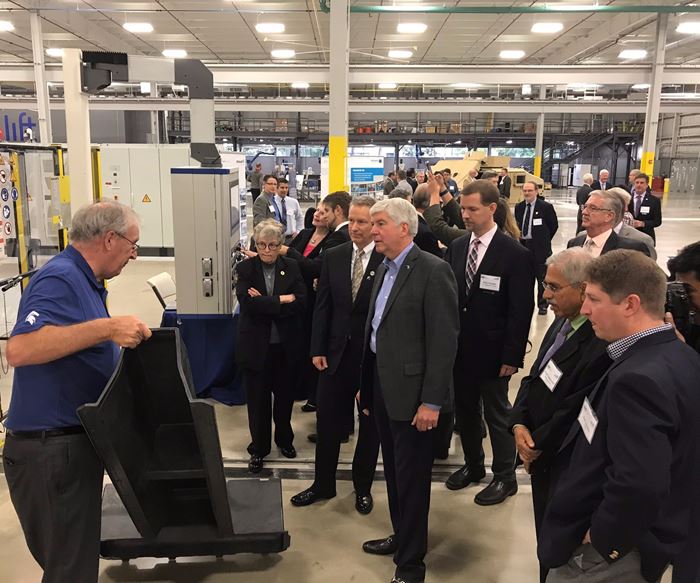

The Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN, US), and LIFT-Lightweight Innovations for Tomorrow (Detroit, MI, US), celebrated Manufacturing Day on Oct. 6 by cutting the ribbon on and hosting an open house at the new IACMI/LIFT manufacturing innovation facility in Detroit.

The event included more than 160 Detroit-area K-12 students participating in hands-on STEM activities, and comments from Michigan Governor Rick Snyder, Detroit Mayor Mike Duggan, U.S. Senator Debbie Stabenow, Congresswoman Brenda Lawrence, Michigan State University President Lou Anna K. Simon, IACMI CEO John Hopkins and other leadership stakeholders for both institutes.

The center houses the LIFT headquarters and the IACMI Vehicles Scale-Up Facility, the research and development hub for the IACMI Vehicles Technology Area. This event capped a near $50 million investment in world-class manufacturing equipment value and improvements to the Corktown facility, recognizing the future of innovative research in composites and metals to be done there.

IACMI’s half of the facility includes several large pieces of composites manufacturing equipment that will be made available for development of materials and processes for autocomposites production. The centerpiece is a 4,000-ton Schuler (Göppingen, Germany; Canton, MI, US) press, designed for high-pressure resin transfer molding (HP-RTM), sheet molding compound (SMC) and thermoplastic compression molding. It features a 12-by-8-ft platen, 9.2 ft of daylight and a 7.9-ft stroke. And, because of the low ceiling in the building, 15 ft of the press is located below grade in a 20-by-40-ft concrete basement dug exclusively to accommodate the machine. Located next to the Schuler press will be, by early 2018, a Hennecke (Lawrence, PA, US) HP-RTM injection machine.

Adjacent to the Schuler press is a 3,000-ton Milacron injection molding machine with a 6-axis robot for part removal and, eventually, preform insertion for injection overmolding applications. Finally, users of the IACMI facility will have access to a Preform Lab that includes a C.A. Litzler (Cleveland, OH, US) prepreg machine, which can manufacture prepreg up to 12 inches wide at speeds up to 10 fpm. Still to come in the lab is an automatic tape layer.

All of this equipment will be made available to IACMI members on a project basis to develop and evaluate materials and processes for the high-volume manufacture of composite parts and structures for cars and trucks. Jim deVries, formerly of Ford and currently a Vehicles Technology Area consultant for IACMI, noted that making such high-quality capital equipment available to automotive OEMs is hugely beneficial. Currently, he said, OEMs or Tier 1s that want to develop a composites manufacturing process but lack the equipment to do so must borrow machinery time during off hours from composites fabricators. This is often inconvenient and can disrupt production for the manufacturer. He said the IACMI Vehicles Scale-Up facility offers state-of-the-art equipment, knowledgeable support staff and ease of access of the type unavailable anywhere else in the American composites community.

The institute’s co-location was announced in 2015 and one year later, the two institutes celebrated their combined investment in the innovation center, which began the acquisition and installation of equipment in the joint facility. IACMI and LIFT’s investments have allowed institute members, partners and others in the industry to conduct research and development projects, in both lightweight metals and advanced composites. It also continues to provide education spaces for students and adult learners focused on developing careers in the composites and lightweight materials industries.

“I appreciate the incredible investment that these two world-class research and development institutions are making in our state and the city of Detroit,” Gov. Rick Snyder said. “With Michigan’s talented workforce and reinvented business climate, I am confident that this partnership between IACMI, LIFT and our state will be an extremely prosperous one.”

Manufacturing Day is a national celebration of modern manufacturing, encouraging the next generation of STEM-workers to recognize the innovative possibilities of the future of manufacturing in the U.S.

The Detroit-area students participating in the event engaged in hands-on STEM events such as building hover-crafts out of compact discs, and creating an automobile out of different materials and testing the characteristics through virtual reality. They also had the opportunity to tour the facility and speak with engineers and Michigan State University engineering students about career options. The students gathered with more than 200 industry, government, and university attendees to join for speaking remarks where they learned more about the impact manufacturing has on the Detroit community, the State of Michigan and the country from the leaders on hand for the event.

“Being headquartered in Detroit, it is critical for our institute to open our doors to Detroit-area students to learn about LIFT and to understand the opportunities for engineering careers and innovative research that will affect the future of the auto industry – and is being done right here in our community,” said LIFT Executive Director, Lawrence E. Brown. “We appreciate the support from the U.S. Department of Defense, the Michigan Economic Development Corporation, our founders at the University of Michigan, the Ohio State University and EWI, as well as our LIFT members who have engaged in this facility and continue to support the future innovations that will be made here.”

Materials research and workforce development play key roles in the future of the automobile industry. “This event gives us the opportunity to showcase the opportunities in manufacturing innovation for the auto industry through composites research and development,” said IACMI CEO Hopkins. “We appreciate the support from the U.S. Department of Energy, Michigan Economic Development Corporation, the city of Detroit, Michigan State University, and our more than 150 IACMI members who have made this facility possible for IACMI.”

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)