Lufthansa Technik, Diab develop greener composites for interior cabin components

Aeroflax flax fiber-based prepreg and one-step thermoplastic manufacturing process for 100% recyclable panels production pioneer lighter weight, reduce CO2 emissions.

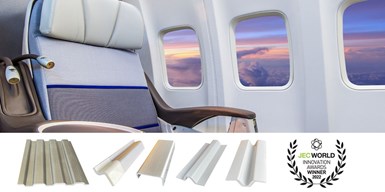

Aeroflax application on aerospace cabin interiors. Photo Credit: Lufthansa Technik

With the pursuit of sustainable aviation underway, Lufthansa Technik (Hamburg, Germany) and Diab (Laholm, Sweden) are seeking to pioneer greener composite materials — recyclable or bio-sourced — and manufacturing processes for cabin-related components. According to Aviation Week, while Lufthansa Technik is developing a material that uses vegetal fiber and a bio-based resin to reduce CO2 emissions (versus glass or carbon fiber), Diab has found a way to recycle the thermoplastic foam in aircraft interior parts.

Lufthansa Technik’s Aeroflax is said to be “the first renewable, eco-efficient and aerospace-grade pre-impregnated fabric [prepreg],” according to Christian Seifert, Lufthansa Technik’s product manager, cabin modification. Originally initiated three years ago with a partnership with Bcomp (Fribourg, Switzerland), the material is now at a technology readiness level (TRL) of 5-6. Aeroflax incorporates ampliTex and powerRibs flax fiber reinforcements and the resin uses agricultural waste, such as from corn harvests, as feedstock. In addition to reducing CO2 emissions, the company notes on its website that Aeroflax can save up to 20% in weight; applications can include sidewall or ceiling panels, door frame lining or lavatory shrouds.

Diab’s 100% recyclable thermoplastic panels shown here were produced in a single-step process in partnership with Aviacomp. Photo Credit: Diab

Diab has reportedly pioneered a thermoplastics manufacturing process to produce 100% recyclable panels (using recycled content from production waste) for cabin interiors that are compliant with cabin interior application requirements and saves up to 10% in weight. The process, which earned the company a 2022 JEC Innovation Award, combines its Divinycell F structural foam core and thermoplastic skins, and is said to save up to 20% of the cost of manufacturing and offers higher mechanical and fire resistance behavior than current honeycomb core and phenolic resin/glass fiber solutions.

“At the start of the project, we decided to think out of the box and push the limit of existing materials and processes,” Aurelien Lafforgue, market segment manager, aerospace & industry at Diab, says. “We wanted to simplify the manufacturing process as much as possible with a single-step process, with the panel ready to use out of the mold as the ultimate target.”

Consequently, Diab decided to avoid using an adhesive film and instead welded together skins and core to create adhesive properties much higher than the current solution with phenolic resin. In addition, Diab decided to use a new generation of coating systems developed for the cabin interior market that can effectively be “welded” to the panel as it is molded in a single, one-step process using induction heating. This method takes minutes rather than hours, Diab says, which is the case when using multiple layers.

Together, Lufthansa Technik and Diab’s innovations also made finals for the Crystal Cabin Awards 2022.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;maxWidth=300;quality=90)