Markforged highlights Sidus Space 3D-printed composite satellite

The two partners have spent the last four years working on LizzieSat, a partially 3D-printed satellite that is set to launch on the SpaceX Transporter-9 rocket in 2023.

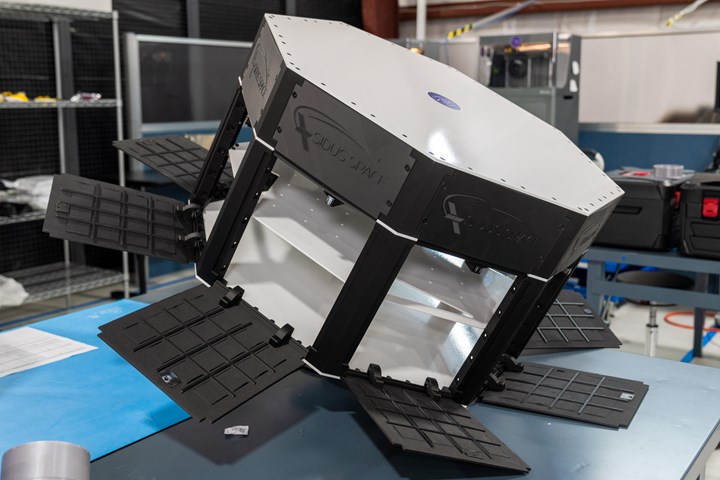

Sidus Space Inc. (Cape Canaveral, Fla., U.S.), a Space-as-a-Service satellite company, has unveiled a video from Markforged (Watertown, Mass., U.S.), a key partner in the development of Sidus’ 3D printed LizzieSat satellites, which are set to launch on the Space X Transporter-9 rocket in 2023.

As seen in the video (below), the satellite was built using The Digital Forge Platform by Markforged and Onyx FRA, a flame-retardant and traceable version of its continuous carbon fiber-reinforced nylon material. The accuracy of the 3D-printed parts are said to be so great that “satellite pieces can snap together like LEGOs,” eliminating the need for metal screws. Making Lizzie’s structure as lightweight as possible also enables Sidus to fit more customer mechanisms within the satellite itself — and thus also cutting down on the number of satellites in space.

“Markforged 3D printers initially played an important role in our successful External Flight Test Platform (EFTP) mission, an on-orbit external experimental facility that was hosted on the NanoRacks International Space Station External Platform (NREP),” Carol Craig, Sidus Space founder and CEO says. “Building on the success of our EFTP program, we have continued to leverage Markforged solutions in the development of LizzieSat.”

Sidus Space’s LizzieSat multi-purpose constellation is designed to meet the precise conditions of commercial and governmental demands in an increasingly interconnected, cloud-based and data-driven world. The platform aims to take advantage of a shift away from static and low-frequency satellite imaging and geospatial solutions toward on-demand access of real-time geospatial intelligence.

By leveraging Markforged 3D printers, Sidus Space has been able to fabricate components quickly and effectively for multiple programs, which enables the company to meet customer requirements in a cost-effective and timely manner. Sidus Space has a broad range of Space-As-a-Service offerings including space-rated hardware manufacturing, design engineering, satellite manufacturing and platform development, launch and support services, data analytics services and satellite constellation management.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

.jpg;maxWidth=300;quality=90)