Markforged

10 Fawcett St.

Cambridge, MA 02138 US

857-600-0415

markforged.com

About Markforged

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Markforged Supplies the Following Products

- 3D printing

Editorial, News, and Products

-

VoxelMatters report reveals top companies in composites AM

The new market study identifies key players in a $785 million global market that has grown by 21% year on year.

-

Composites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

-

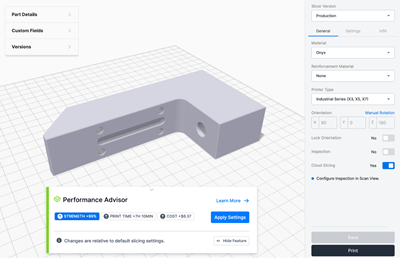

Markforged optimizes 3D-printed part performance with Performance Advisor

The physics-based analysis method is use case independent, automatically providing print settings that will give users options to increase part strength while optimizing for cost and print time.

-

Markforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

-

Markforged introduces Digital Source platform for manufacturer-certified parts

Digital Source aims to solve supply chain challenges with licensed, digital inventory printed through Markforged’s global 3D printer network at the point of need.

-

Markforged completes transition to global headquarters

With its Waltham, Massachusetts headquarters, the composites additive manufacturing specialist unites its corporate and research and engineering branches.

-

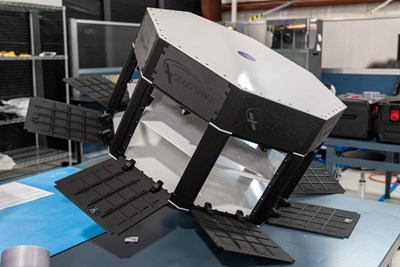

Markforged highlights Sidus Space 3D-printed composite satellite

The two partners have spent the last four years working on LizzieSat, a partially 3D-printed satellite that is set to launch on the SpaceX Transporter-9 rocket in 2023.

-

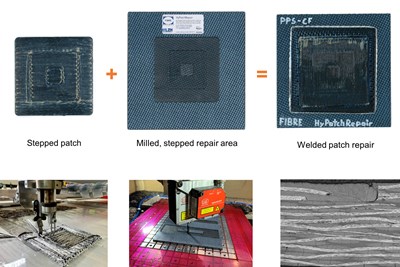

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

Markforged Billerica manufacturing facility achieves ISO 9001:2015 certification

Certification reflects Markforged’s customer-centric culture built around quality and reliability in the additive manufacturing space.

-

Markforged Simulation software features virtual testing capability

Virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to help lower cost and speed production.

-

Composites Association of New Zealand returns to in-person conferencing

Following the pandemic, CANZ members were brought back together to present new innovations, pose new industry goals and ultimately strengthen bonds within the New Zealand composites community.

-

FMG releases market analysis on advanced materials

U.K.-based Future Materials Group (FMG) has issued a new report that assesses the outlook for and opportunities in the advanced materials sector.

-

Vestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

-

Purdue-related startup Araqev creates quality-control software for additive manufacturing

Araqev software expected to help reduce estimated $2 billion in global losses when using AM through machine learning models that simulate shape deviations for future prints.

-

Markforged expands software offering with acquisition of Teton Simulation

Integration of cloud native simulation software into Markforged’s Digital Forge platform will enable manufacturers to validate advanced composite parts for demanding production applications.

-

Predicting and mitigating failure in composite parts

Understanding the complexity of composites manufacturing resides in studying the design challenges inherent to fabrication, as much as the physics aspect. To serve this effort, CW introduces a new column, “Predicting Failure.”

-

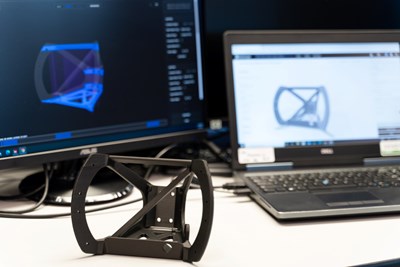

How to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

-

Markforged Director and Co-Founder Greg Mark departs from company

Effective Dec. 29, 2021, Mark leaves behind significant technological contributions to the additive manufacturing company.

-

Markforged launches software to scale additive manufacturing

Called Eiger Fleet, new cloud-based software enables more control and automation in connection with Markforged 3D printers.

-

People in Composites: August 2021

Markforged, Fiberline Composites, Firefly Aerospace, Inhance Technologies, Exel Composites and Lockheed Martin announce new position appointments in the composites industry.

-

Markforged launches aerospace-ready traceable composite materials

Onyx FR-A and Carbon Fiber FR-A materials meet FST requirements, come with traceability and adhere to specifications approved by the National Center for Advanced Materials Performance (NCAMP).

-

Markforged next-generation fiber-reinforced 3D printer

Markforged will debut its newest continuous fiber-capable 3D printer, the FX20, at Formnext in November 2021.

-

Markforged goes public with merger to one

The 3D printer company’s merger with special-purpose acquisitions company (SPAC) one is expected to close in summer 2021.

-

New 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

-

3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

-

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

-

C-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

-

Markforged, MSC Software partner on 3D printer simulation tools

Customers will have increased access to MSC’s process simulation, performance modeling and material analysis tools for Markforged 3D printers.

-

On the road with CompositesWorld

CW Senior Editor Scott Francis offers a recap of recent composites industries events including CAMX 2019 and SPE ACCE 2019.

-

CAMX to host Additive Manufacturing Workshop for Composites

Co-located with CAMX, the event explores the connection between AM and continuous fiber reinforcement.

-

Markforged launches first FR continuous fiber-reinforced plastic for 3D printing

V-0 rated Onyx FR to open new applications in aerospace, defense and automotive

-

Markforged to build European headquarters in Dublin, Ireland

The Dublin headquarters is expected to hire 100 new employees and serve as phase one for the 3D printer manufacturer’s global growth initiative.

-

Markforged raises $82 million to expand product line

The continuous fiber composite 3D printing pioneer will use capital to accelerate mass production printers, global expansion and new materials, such as FR aerocomposites.

-

Moving continuous-fiber 3D printing into production

With patents proliferating and production applications emerging, 3D printing with continuous fiber reinforcement is poised for significant market growth.

-

3D printing is missing the third dimension

Emerging processes like continuous fiber manufacturing, in-situ consolidation and tool-less manufacturing are bringing composite 3D printing into the third dimension.

-

Episode 5: Greg Mark, Markforged

Greg Mark, founder and CEO of Markforged, discusses his journey of working with composites in additive manufacturing.

-

Composites in transit: Rolling robotic “stuff carrier” the new must-have

PPF’s Gita can move at a human walking pace or can accelerate up to 35 kph, fast enough to keep pace with a runner.

-

Additive manufacturing comes to composites fabrication

The use of continuous fiber in additive manufacturing systems is not trivial, but it is being done. As this fabrication technology evolves and matures, options for applying it in everything from automotive to aerospace to consumer composites will expand tremendously, creating a host of new opportunities for the composites industry. Read here for who is providing what kind of additive manufacturing technology for use in composites fabrication.

-

3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

-

CAMX 2014 show report

Bigger, better and more inclusive than any previous U.S. composites trade event, the inaugural show turns North American eyes forward to the future.