Mikrosam filament production line supports Amargo tank production

Mikrosam system features will support the production of Amargo’s chemically resistant pressure vessels or hydrogen storage in industrial plants.

Consulting and production company Amargo (Koprki, Poland) is now home to Mikrosam’s (Prilep, Macedonia) newest, floor-based, state-of-the-art filament production line for chemically resistant tanks or hydrogen storage in industrial plants. Using wet-impregnated fibers, this machine can produce composite tanks in a diameter range of 200-4,300 millimeters and a length range up to 12,000 millimeters with mandrel shafts.

Amargo covers many applications through concept, project, production, delivery and full service during the whole lifetime of the tank. In addition, the company has teamed up with two technical universities — Warsaw and Wroclaw — and is working on a 3-year project entitled “Development of an intelligent construction for a composite pressure vessel with a big hinged bottom,” that will enable the company to design and produce even complex tanks using the filament method winding process.

“Amargo has been supporting many industries for over 18 years by providing chemical-resistant tanks with complete installations and the necessary additional equipment and controls,” Szczepan Gorbacz, president of the management board of Amargo, says. “When the operating conditions of the tank, including the corrosive environment, temperature and pressure, are very demanding, solutions based on materials from the thermoplastic group, e.g.. polyethylene PE100 and polypropylene PP-H, are no longer sufficient. It is then necessary to use resin tank structures and glass fiber reinforcement, preferably with the use of continuous fiber.”

Amargo chose Mikrosam for its experience, expertise, engineering support, and flexibility in equipment design and integration.

Mikrosam’s system features a filament winding machine, an impregnating bath system for deep impregnation, a fiber creel, a fiber delivery system, software for programming and a quality inspection system. It has a single spindle, four axes of interpolation and a carriage floor-based configuration. Normally, the machine uses glass fiber, but it can be converted to carbon fiber, which the company says is important, especially for high-pressure tanks and hydrogen storage tanks. A fiber delivery system guides and transports fibers up to the resin bath and mandrels with minimal fiber damage. The ceramic eyelets minimize friction between the fibers as they are guided in a precise order until they reach the resin bath. Designed for high production speed, the deep immersion bath has 32 tows (fibers) for optimal impregnation quality.

“This machine offers a variety of possibilities, from producing smaller hydrogen tanks, up to large high-volume chemical resistant and water tanks” Vele Samak, vice president of Mikrosam, notes. “The flexibility of Mikrosam’s designs enables it to upgrade the delivering eye with a fifth controlled axis and a second roller-impregnated bath.”

The machine is also equipped with WindingExpert software, which can generate mandrels and patterns, simulate parts, produce parts and export FEA data (e.g., Nastran, Abaqus), among other features. For advanced control, the system offers a quality control system with SCADA integration. By using this manufacturing historian, the customer monitors and controls critical filament winding parameters. This includes precise tension control of the continuous fibers, accurate resin flow control and maintaining consistent winding angles. This ensures that Amargo can guarantee high-quality, well-balanced and reliable tanks.

Along with this new installation, Amargo and technical university engineers are working to prepare special detection systems — sensors that can measure elastic waves excited by piezoelectric transmitters, installed on the outer glass fiber-reinforced polymer (GFRP) layer of the tank. As aggressive chemical agents stored under elevated pressure can cause significant damage to both people and the environment, it is essential to develop systems for early damage detection and structural integrity monitoring of such vessels. These sensors also help to reduce maintenance costs and unforeseen operational breaks.

Additionally, as part of a complete solution, Amargo is incorporating the use of digital twin solutions.

Related Content

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

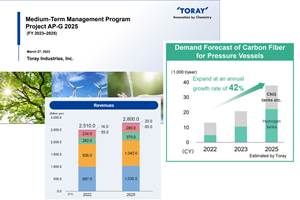

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreRead Next

Mikrosam, H2Storage collaborate on 300+-liter Type IV hydrogen tanks

Automated filament winding cell achieving wind speeds of 6 meters/second improves production performance, shortens curing cycle for serial production of 700-bar Type IV tanks.

Read MoreAFPT combines tape winding, placement into one tool

Typically separate processes, the company’s new vessel winding head (VWH), merged with a multiple tape laying head (MTLH) progresses composite pressure vessel development.

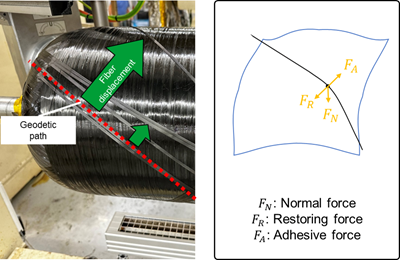

Read MoreIVW research to better determines fiber friction coefficient

Highly variable system development contributes to the increasing precision and efficiency in the manufacture of filament-wound composite components.

Read More

.jpg;maxWidth=300;quality=90)