NCC develops cryostat device and test method for cryogenic composites testing

Targeting hydrogen applications, novel technology and method provide a solution for screening a wide selection of materials to better understand their properties at cryogenic temperatures.

The National Composites Centre (NCC, Bristol, U.K.) has developed a novel cryostat and test method that enables the screening of composite material performance at cryogenic temperatures in an ultra-fast and cost-effective way.

The device and accompanying test method provides a solution for screening a wide selection of materials, highlighting those most suitable for detailed material testing using conventional methods. The concept will help to address the challenge of limited existing U.K. capability in understanding the properties of materials at cryogenic temperatures. According to the NCC, to help industry achieve ambitions for hydrogen-powered aircraft requires advances in cryogenic technology, and substantial material data at low temperatures.

To enhance collaboration and U.K. industry advancement, the NCC will offer access to the hardware in 2024, as part of its Hydrogen program, driving reductions in the time, cost and complexity of cryogenic testing.

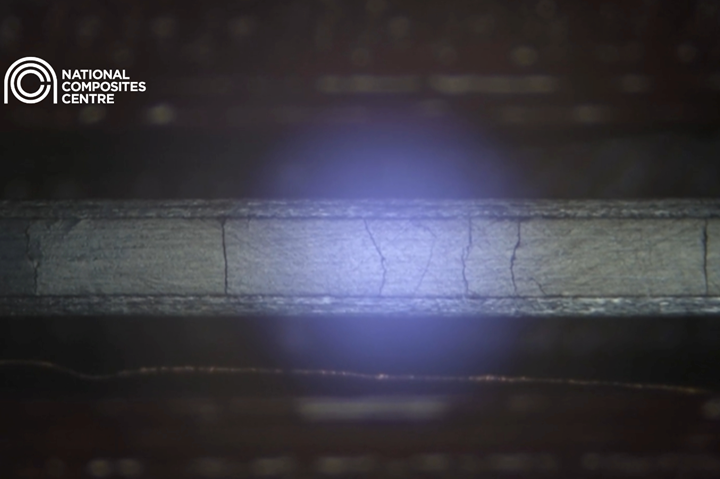

A key feature is the cryostat’s optical access, allowing material specimens to be viewed during the test process. In particular it looks at the cracks that are developing in the composite material, focusing on any microcracking. The test has a cycle time of approximately 30 minutes to cool and test, ensuring a high throughput of test specimens. This is achieved by using cryogenically cooled nitrogen gas, using a design with a low thermal mass and volume.

The NCC is working with the National Physical Laboratory (NPL) to validate the cryostat design and quantify data repeatability, to ensure it meets industry standards.

“The cryostat concept will reduce barriers to entry and increase the rate of cryogenic materials testing, helping engineers and researchers to develop new products for the emerging liquid hydrogen industry,” Matt Kay, principal engineer at the NCC, says. “It forms part of the NCC’s journey in developing specialist expertise to support the U.K.’s transition to the hydrogen economy.”

Companies interested in joining the NCC Hydrogen program and opportunities to collaborate on the cryostat can contact hydrogen@nccuk.com to express interest.

Related Content

-

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.