Type V pressure vessel enables lunar lander

Exploratory IM-1 lunar landing mission to feature a unique, all-composite unibody Type V pressure vessel designed for cryogenic propulsion.

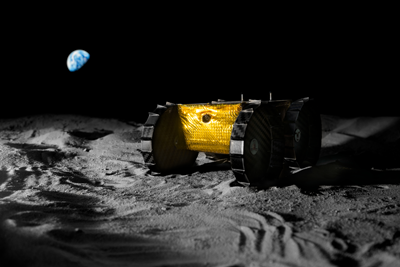

Intuitive Machines' Nova-C lunar lander will investigate a potential landing site for the Artemis III mission, which will return humans to the moon. Photo Credit: Intuitive Machines

With each launch, the Artemis program brings humans closer to a return to the moon. Intuitive Machines (Houston, Texas, U.S.), one of the providers in NASA’s (Washington, D.C., U.S.) Commercial Lunar Payload Delivery Services (CLPS) initiative, is preparing its Nova-C lunar lander for a targeted launch aboard a SpaceX (Hawthorne, Calif., U.S.) Falcon 9 launch vehicle in mid-November 2023. The IM-1 mission hopes to land an uncrewed lunar lander near the moon’s south pole, demonstrating navigation, landing and communication technologies. The mission will also study how the rocket plume interacts with both the lunar surface and the space weather environment at the landing site — a region being assessed for the Artemis III mission that will place astronauts on the moon.

The IM-1 mission boasts a lot of firsts. Not only will Intuitive Machine’s craft be the first U.S. spacecraft to land on the moon since the 1972 Apollo 17 mission, it also will be the first commercial lunar lander. The Nova-C is also the first craft to use a liquid oxygen (LO2)/liquid methane (LCH4) propulsion system in a space environment.

The LO2/LCH4 system is of interest for multiple reasons. It is considered a potentially “greener” alternative to traditional propulsion methods such as hydrazine-based systems. Methane-based systems have a high specific impulse (ISP), or amount of force released per second, yet their density allows for storage in smaller tanks. In addition, methane is plentiful in the outer solar system, opening up the potential to refuel for missions to Mars and beyond. However, the use of such a combination requires tanks that can withstand cryogenic temperatures — LO2 and LCH4 have boiling points of -183ºC and -162ºC, respectively. The extreme temperatures required for both fuels present engineering challenges for such propulsion systems.

Consequently, the type of tanks Intuitive Machines used for this application became an important consideration. Pressure vessels that are made of metal (Type I) add extra weight to the payload, and Type II and III tanks comprising composite overwrapped metal (composite overwrapped pressure vessel or COPV) are subject to delamination and embrittlement when subjected to extreme temperature cycling. Instead, Intuitive Machines began exploring the possibility of using Type V pressure vessels for the mission.

“We were looking for an extremely lightweight tank that can hold cryogens and hold pressure,” says Trent Martin, Intuitive Machines vice president of lunar access.

Type V composite tanks

Type V pressure vessels — which have found use in industrial gas storage tanks, as well as natural gas and hydrogen fuel cell vehicles — are linerless and constructed of carbon fiber composites. Their lightweight, all-composite construction makes them suitable for applications where weight directly affects fuel efficiency and vehicle performance. Carbon fiber composites are also often selected for applications that require a high strength-to-weight ratio and resistance to corrosion. These properties also enable storing a significant amount of compressed gas in a relatively small and lightweight container.

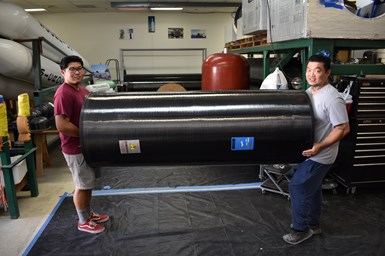

SSLC’s Pressurmaxx tanks offer a lightweight design suitable for cryogenic applications. Photo Credit: Scorpius Space Launch Co.

To incorporate composite tanks into its Nova-C lunar lander, Intuitive Machines turned to Scorpius Space Launch Co. (SSLC, Torrance, Calif., U.S.), a manufacturer of a unique Type V pressure vessel design using a unibody construction suitable for cryogenic use. SSLC’s Pressurmaxx tanks have been successfully tested at cryogenic temperatures as low as -196°C, and at pressures up to 552 bar.

Intuitive Machines performed more than 150 different tests on SSLC’s Pressurmaxx composite linerless tanks as part of the development and certification process, subjecting the tanks to testing for temperature cycling, vibrations and impact.

“The tanks SSLC created weigh significantly less than traditional options, enabling Intuitive Machines to deliver more mass to the lunar surface that will pave the path for humanity’s sustainable return to the moon,” says Martin.

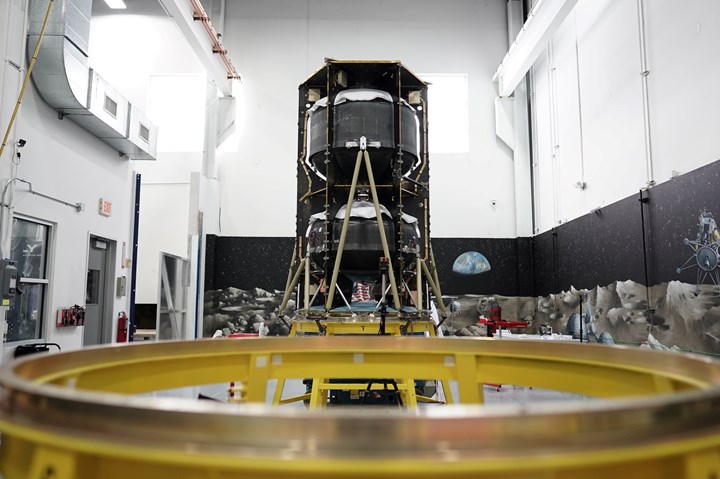

Intuitive Machine’s Nova-C lander is equipped with two SSLC Pressurmaxx tanks that enable its LO2/LCH4 propulsion system. Photo Credit: Intuitive Machines

More than lightweighting

Carbon fiber has become synonymous with lightweighting — and that is indeed one important consideration for spaceflight, but there are many other advantages that make the material a good choice for space applications.

“Some people think that the only reason why you want something made out of carbon fiber is because it’s lighter, but that’s really just one aspect of it,” reiterates SSLC president and CEO Markus Rufer. “Composite tanks don’t corrode. Our [tanks] are completely resistant to almost all of the chemicals that are used in space [applications].”

Moreover, because of the wide range of extreme temperatures that materials are subjected to in spaceflight, as well as the use of cryogenic propellants, any materials used must be able to withstand drastic changes in temperature. This is another advantage of the unibody design of SSLC’s pressure vessels. “With our tanks, you don’t have a secondary material, which means they can take a lot of temperature cycling and cold shock abuse,” Rufer says.

SSLC’s tanks are designed as unified structures and do not require additional support elements of any kind. Because composite materials have a very low coefficient of thermal expansion (CTE) relative to metal structures, the need to design around these concerns is minimized. Pressurmaxx vessels can hold several thousand psi pressure, are compatible with all common fluids and gases used for aerospace applications and cover a temperature range of -196°C to 77°C. Built with SSLC’s proprietary Sapphire 77 cryogenic resin system and Hexcel (Stamford, Conn., U.S.) carbon fiber, the tanks contain no metals, fasteners, welds or additional sealants. And while the resin formula is proprietary, Rufer says the ingredients — and the carbon fiber materials — are ones commonly used in the composites industry.

“We actually made a point not to go to exotic solutions, scarce materials or single-sourced materials because we didn’t want to be susceptible to supply chain fluctuations and issues,” says Rufer. “We wanted to have a fiber and resin formulation that was readily available.”

A push for cleaner systems

One consideration that factored into Intuitive Machine’s choice of LO2/LCH4 for the propulsion and steering system for its Nova-C lander is growing environmental awareness that extends into space exploration. Traditionally, some of the substances used for propulsion systems, such as hydrazine, have been very toxic. In contrast, LCH4 combustion results in exhaust plumes consisting primarily of water, with minimal carbon dioxide and nitrogen oxides. This makes it one of the cleanest burning rocket propellants available, second only to hydrogen. Nova-C is equipped with two SSLC Pressurmaxx tanks — one containing LCH4 and the other containing LO2. According to Rufer, while this system is not completely emissions-free, it is a very clean system compared to traditional propulsion systems.

“We’ve become more environmentally aware, not just what we do on this planet, but also to make sure that we’re not contaminating space,” says Rufer. “The reason this system wasn’t already popular is because of the need for cryogenic tanks.”

An evolution in tank development

When SSLC began developing its tanks in the early 2000s, it set out on a path to address the numerous issues that can arise with Type V pressure vessels. “We stumbled over the usual problems,” says Rufer. “For example, the tanks did start weeping. Overall, they held pressure, but once we’d start doing temperature cycling, we would begin having leaks at relatively low pressures, maybe 3.5 to 5 bar. We just could not hold pressure when testing with liquid nitrogen and microcracking issues manifested.”

At the time, many tanks were fabricated from two halves joined with a belly band. However, it was difficult to ensure the resulting joint was completely leak-free. In addition, the flanges on the polar boss openings of tanks were often metal, which caused issues with the adjoining composites that have different CTEs — the tanks had a tendency to shrink or expand at a different rate than the flanges.

“When you have two different types of materials that want to fight each other in a joint, that means it’s going to fail,” says Rufer. “So, early on we moved to making the bosses out of carbon fiber composites. We also moved away from the belly band approach and devised different technology for that joint.” SSLC has developed its own approach to joining its tank halves that is based on scarfing, similar to the scarf joint that has proven effective for decades in structural composite repairs on aircraft.

SSLC says the full potential of Type V pressure vessels lies in using fuel tanks as primary load-bearing structures in spacecraft designs. Photo Credit: SSLC

A step toward future spacecraft

While the tanks on the IM-1 mission were selected primarily for their weight savings and cryogenic properties, SSLC is hoping the mission will help pave the way for enabling a whole new type of spacecraft.

SSLC has a particular interest in rocket designs that use propellant tanks as primary load-bearing elements of the vehicle. Rufer explains that the company’s tank configurations combine primary and secondary support structures into one single propellant tank that is significantly lighter, stiffer and stronger than traditional tanks. SSLC’s all-composite tanks incorporate such features as polar bosses (including the boss threading), external structural stringers and internal slosh baffles. Rufer says that because the tanks are unibody structures, they can effectively become the primary structure of a launch vehicle or a spacecraft.

“All the features you want in or on this tank are, in effect, growing out of the tank wall. So, it is one piece and forms a load-bearing chassis,” he notes.

SSLC’s sister company Microcosm Inc. (Torrance, Calif., U.S.), is using Pressurmaxx tanks as a basis to design entire spacecraft comprising a single, integrated carbon fiber structure. In collaboration with SSLC, Microcosm has developed a combined structure/propellant tank for smallsats that it calls a unibody pressurized composite structure (UPCS). The spacecraft’s construction integrates the propellant tank and does not require additional support elements of any kind, yet still allows easy installation of various payloads and bus subsystems. The solution reduces overall spacecraft mass by 20-40%, depending on configuration.

While he acknowledges that traditional spacecraft designs and propulsion systems have the advantage of flight heritage on their side, Rufer believes that an approach that enables propulsion tanks to perform double duty as the spacecraft body is the way of the future. He hopes the IM-1 mission is a step toward realizing the full potential that Type V tanks have to offer.

“This [lunar lander] is one application where the Type V tanks finally have an opportunity to demonstrate some of what they can actually do,” Rufer says. The next step, and the real benefit of this technology, is when you begin to use its full potential — and that is when all of it becomes your primary structure.”

Related Content

Innovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreNovel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreRead Next

Composites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

Read MoreCarbon fiber composite liner-less pressure tank handles cryogenic temps

Cimarron Composites has made a leap forward in all-composite cryogenic tank development.

Read More