National Composites Centre (NCC)

Bristol & Bath Science Park

Feynman Way Central, Emersons Green

Bristol, South Gloucestershire BS16 7FS GB

44 117 370 7600

comms@nccuk.com

nccuk.com

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Editorial, News, and Products

-

University of Bristol launches composite materials to space for ISS testing

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.

-

NCC receives funding to build Cygnet Texkimp-designed carbonization research lines

The National Composites Center is to build precursor and carbon fiber research lines to enable innovation in U.K. composites production.

-

NCC welcomes Scottish Renewables to SuSWIND steering board

Scotland’s renewable energy trade body joins several other members to guide and support technology advancement for recyclability and future wind blade development.

-

Workforce report provides insight into evolving hydrogen landscape

The National Composites Centre and Tank Storage Association identify future skills demands, call for action to meet U.K. hydrogen targets.

-

NCC leads composites manufacturing phase of eXtra wing demonstrator

Key structural elements for a 6-meter section of the Airbus biomimetic wing were undertaken by NCC engineering specialists to produce 28 one-off flying parts.

-

Composites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

-

Plataine expands NCC's AI, IoT optimization capabilities

Under this partnership, the NCC will leverage technologies such as time-sensitive material management and Plataine’s Digital Twin to further develop its composites R&D.

-

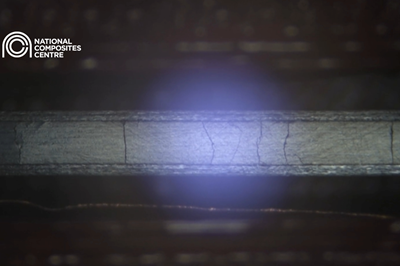

NCC develops cryostat device and test method for cryogenic composites testing

Targeting hydrogen applications, novel technology and method provide a solution for screening a wide selection of materials to better understand their properties at cryogenic temperatures.

-

SUSPENS project shares one-year progress, next steps

European project dedicated its first year to sustainable materials development and prototype manufacture, looks to validating performance.

-

Demonstrator project targets circularity solutions in carbon fiber composite sports equipment

The Carbon Fibre Circular Alliance (CFCA) brought together OEMs and technical partners to reclaim short carbon fibers from end-of-life sports equipment, realign into continuous prepreg tapes and remanufacture into new equipment.

-

Panel discussions, presentations highlight intelligent process technologies for composites

JEC World 2024: In addition to providing insights and success stories regarding automation and digitalization opportunities in composites, sensXPERT offers attendees a free material characterization opportunity.

-

Sonichem launches bio-based materials project for automotive

U.K. initiative, with the NCC, CPI, SHD Composites, Scott Bader and Polestar will work to convert biomass byproduct into lignin for automotive plastics, resins and composites.

-

NCC commissions Cygnet Texkimp filament winder for hydrogen development

Multifunctional four-axis winding system offering fiber flexibility will underpin the NCC’s work in testing and manufacturing pressure vessels leading to commercial production.

-

NCC composite cryogenic tanks successfully tested with LH2

Thirty-liter single-piece and split-piece tank constructions underwent various pressures and test cycles while maintaining full integrity. End boss design testing is underway.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

National Composites Centre launches net-zero flight plan

New technology innovation partnership program with South West Europe IAAPs and the universities of Bristol and Bath will focus on hydrogen fuel systems to increase U.K. technology, infrastructure and innovation capabilities.

-

Lucideon, NCC partner to develop next-gen CMC solutions

This close collaboration will develop, analyze and evaluate advanced materials and applications to support the emerging demand for materials that can survive high-temperature, extreme and harsh environments.

-

On the radar: Technologies for lifecycle analysis (LCA)

Sustainability requirements are driving more companies to conduct LCAs to evaluate the environmental impact of their products and processes. Tools and research in this area continues to evolve.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

JEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

-

Moving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

-

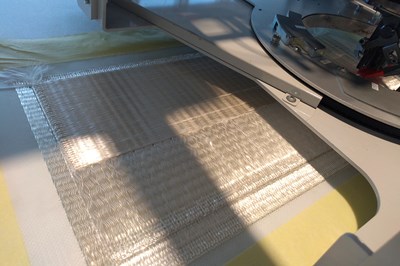

NCC and Synthesites work toward intelligent manufacturing for resin infused composites

The National Composites Centre (NCC) and Synthesites develop an advanced closed loop control system for resin infusion with non-invasive sensors, real-time resin flow monitoring and accurate, in-situ estimation of online viscosity and glass transition temperature.

-

Cecence, NCC and Gen 2 Carbon develop sustainable airplane seatback

Conducted life cycle analyses found significant benefits using recycled carbon fiber, with an 84% reduction in carbon emissions.

-

Sensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

-

National Composites Center and Meggitt demonstrate linear dielectric sensor for liquid composites processing

Research at Cranfield University is further developed via RTM part trials in NCC’s Technology Pull-Through Program