Neural nets can advance composites analysis

British researchers use two neural nets and a 2D image to create 3D models. The architecture is fast, cheap, accurate and more clearly identifies different material phases.

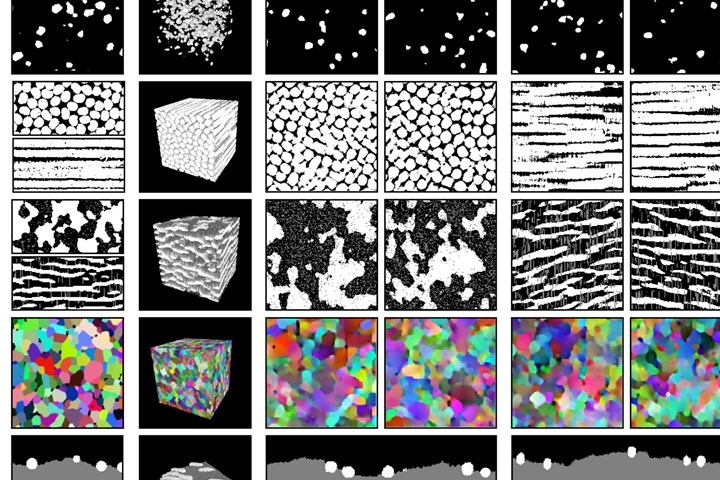

If one neural net is trained with enough 2D data about a structure by another neural net, 3D data can be generated, which can allow analysis of material behavior. Photo Credit: Imperial College London

It’s called “deep convolutional generative adversarial networks” (DC-GANs) and it has the potential to improve the design and production of composites, according to researchers at the Imperial College London (U.K.).

The approach starts with data from 2D cross-sectional designs of composites. Then the DC-GAN tool, which uses two neural networks, running what’s called the “SliceGAN” architecture, is deployed.

Realistic

According to Steve Kench, a PhD student in the Tools for Learning, Design and Research (TLDR) group at Imperial’s Dyson School of Design Engineering (London, U.K.) and lead author of a paper on the subject that appears in Nature Machine Intelligence, “Combining materials as composites allows you to take advantages of the best properties of each component, but studying them in detail can be challenging as the arrangement of the materials strongly affects the performance. Our algorithm allows researchers to take their 2D image data and generate 3D structures with all the same properties, which allows them to perform more realistic simulations.”

Approach

Explains Dr. Sam Cooper, head of the TLDR group and co-author of the paper: “In general, 2D imagining is easier than 3D, but sometimes 3D information is needed to understand material behaviors. SliceGAN can be used to generate 3D data if it’s trained with enough 2D data.”

There are two networks used. “Network 2’s job,” Cooper continues, “is to generate ‘fake’ volumes and network 1’s job is to check that all of the slices of these generated volumes look ‘real’—i.e., like the training data.”

Economical

Cooper notes, ““The performance of many devices that contain composite materials, such as batteries, is closely tied to the 3D arrangement of their components at the microscale. However, 3D imaging these materials in enough detail can be painstaking. We hope that our new machine learning tool will empower the materials design community by getting rid of the dependence on expensive 3D imaging machines in many scenarios.”

Notably, not only did they determine that the DC-GAN approach is cheaper and faster than creating 3D models from 3D physical models, but that it more clearly identifies different material phases within the materials something that it tough to do with conventionally used techniques.

Related Content

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)