NIAR’s ATLAS lab to install Cevotec SAMBA Pro system in 2021

The new system will open multiple options for evaluation and development based on Fiber Patch Placement technology, including material characterizations, application and process development, prototyping and testing.

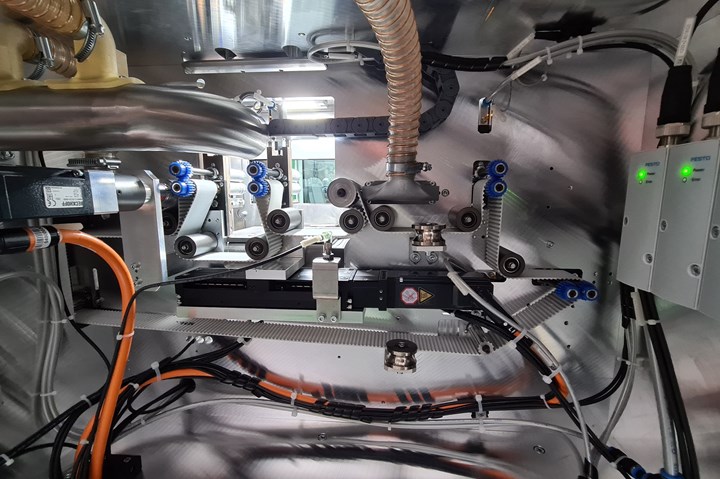

Photo Credit: Cevotec GmbH

The National Institute for Aviation Research (NIAR) at Wichita State University (WSU, Wichita, Kan., U.S.) has announced that it has selected Fiber Patch Placement (FPP) technology to expand its technology portfolio for future composites production technologies. The installation of Cevotec GmbH’s (Munich, Germany) SAMBA Pro Prepreg system at NIAR’s Advanced Technologies Lab for Aerospace Systems (ATLAS) will be ready by end of 2021.

“Together with our U.S. partner Composite Automation, we are excited about this first FPP system in the United States and look forward to future R&D collaborations with NIAR,” states Thorsten Groene, managing director of Cevotec.

ATLAS Director Waruna Seneviratne believes integrating FPP technology in the ATLAS portfolio will lead to pioneering projects. “We are looking forward to receiving the SAMBA system and further advancing our portfolio of robotic-based placement technologies,” adds Seneviratne. “The flexibility of Fiber Patch Placement will be of interest in particular for our R&D partners from the defense community.”

The SAMBA Pro system, featuring an ultrasonic cutting unit and active material cooling, will be operational for application development with industrial customers by end of 2021. The new system at NIAR ATLAS will open multiple options for evaluation and development based on FPP technology, including material characterizations, application and process development, prototyping and testing.

“Wichita is known for having the largest concentration of airframers in the world,” says John Melilli, president of Composite Automation LCC. “NIAR’s ATLAS is the perfect place for the first U.S.-based FPP system, where it will be available to commercial as well as DoD [Department of Defense] clients to demonstrate the advantages of Fiber Patch Placement for the automated production of complex aerostructures.”

The SAMBA Pro Prepreg system was also integrated into Fraunhofer IGCV’s Fiber Placement Center in December.

Related Content

-

Hypersonix receives CMC scramjet manufacturing demonstrator

HTCMC component demonstrates manufacturing of future Spartan scramjet engine required for reusable hypersonic vehicles capable of up to Mach 12 flight.

-

US Air Force selects Integris Composites ballistic body armor

Cratus Wave armor is thin, lightweight and reduces heat stress, providing buoyant personal protection for the 582nd Helicopter Group.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.