Novel composite aims to resolve self-healing material challenges

University engineering researchers have developed and tested self-healing composites capable of self-repairing in place repeatedly without losing healing properties, as well as enhancing resistance to fracture.

University engineering researchers have developed a new self-healing composite material that enables structures to repair themselves in place, without having to be removed from service. This latest technology is said to resolve two longstanding challenges for self-healing materials, and can significantly extend the lifespan of structural components such as wind turbine blades and aircraft wings.

“Researchers have developed a variety of self-healing materials, but previous strategies for self-healing composites have faced two practical challenges,” according to Jason Patrick, corresponding author of the research paper and an assistant professor of civil, construction and environmental engineering at North Carolina State University (NC State, Raleigh). “First, the materials often need to be removed from service in order to heal. For instance, some require heating in an oven, which can’t be done for large components or while a given part is in use. Second, the self-healing only works for a limited period. For example, the material might be able to heal a few times, after which its self-repairing properties would significantly diminish. We’ve come up with an approach that addresses both of those challenges in a meaningful way, while retaining the strength and other performance characteristics of structural fiber composites.”

In practical terms, this means users can rely on a given structural component, such as a wind turbine blade, for a much longer period of time without worrying about failure.

The printed thermoplastic also enhances inherent resistance to fracture by up to 500%.

“By increasing the longevity of these composites, we make them more sustainable,” Patrick explains. “And while wind turbine blades are a good example, structural composites are found in a wide variety of applications: aircraft wings, satellites, automotive components, sporting goods, you name it.”

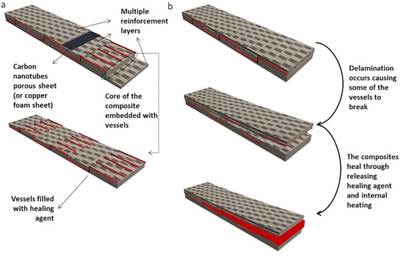

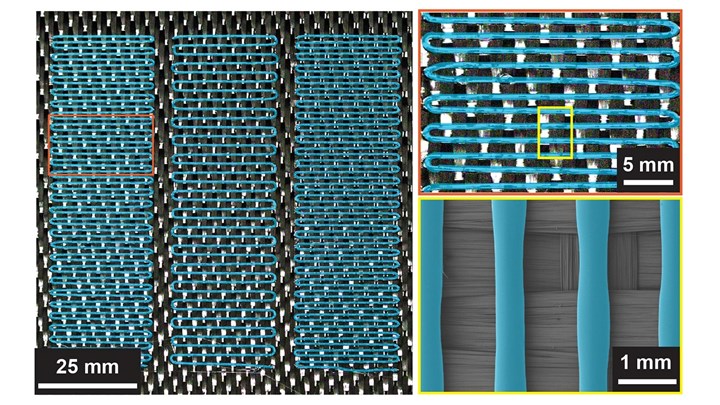

Here’s how the new, self-healing fiber-reinforced composite works: Laminated composites are made from layers of fibrous reinforcement, e.g. glass and carbon fiber, bonded together. Damage most often occurs when the “glue” that binds these layers together begins to peel away from the reinforcement, or delaminate. The research team addressed this problem by 3D printing a pattern of thermoplastic healing agent onto the reinforcement material. The researchers also embedded thin “heater” layers in the composite. When an electrical current is applied, the heater layers warm up. This, in turn, melts the healing agent, which flows into any cracks or microfractures within the composite and repairs them.

“We’ve found that this process can be repeated at least 100 times while maintaining the effectiveness of the self-healing,” Patrick says. “We don’t know what the upper limit is, if there is one.”

The printed thermoplastic also enhances inherent resistance to fracture by up to 500%, meaning it requires more energy to cause delamination in the first place. In addition, the healing agent and heater layers are all made of readily available materials, and are relatively inexpensive.

“While making composites that incorporate our design would be marginally more expensive, the cost would be more than offset by significantly extending the lifespan of the material,” Patrick contends.

Another advantage of the new technology is that, if incorporated into aircraft wings, the internal heating elements would enable airlines to stop using chemical agents to remove ice from wings when aircraft are on the ground, and also to de-ice in flight.

“We’ve demonstrated that this multifunctional technology works,” Patrick says. “We’re now looking for government and industry partners to help us tailor these polymer-based composites for use in specific applications.”

The paper, “Prolonged in situ Self-healing in Structural Composites via Thermo-Reversible Entanglement,” is published in the journal Nature Communications. First author of the paper is Alexander Snyder, a Ph.D. student at NC State. The paper was co-authored by Zachary Phillips and Jack Turicek, Ph.D. students at NC State; Charles Diesendruck of Technion–Israel Institute of Technology (Haifa); and Kalyana Nakshatrala of the University of Houston (Texas).

The work was done with support from the U.S. Air Force Office of Scientific Research, under grant number FA9550-18-1-0048; and the Department of Defense’s Strategic Environmental Research and Development Program, under grant number W912HQ21C0044.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreRead Next

New research on self-healing composites

Researchers have developed a method of allowing composites to self-heal cracks at temperatures well below freezing.

Read MoreCompositesWorld JEC World 2022 recap: CompPair demonstration

Switzerland-based CompPair illustrates how heat triggers the self-healing properties of its recyclable composite materials, repairing a panel in about one minute.

Read MoreCompPair works with ArianeGroup to shape the future of space

CompPair HealTech prepreg helps define the 2025-2050 technology and demonstrators roadmaps for ESA reusable space vehicles.

Read More

.jpg;maxWidth=300;quality=90)