Plataine publishes composite industry survey results

Survey findings provide insight from industry players as they navigate global manufacturing challenges and uncertainties, and sustainability and digitalization implementation.

Final results have been released for the industry survey, “Challenges and Trends in Advanced Manufacturing,” launched by Plataine (Waltham, Mass., U.S.) and distributed by CW. The survey aims to provide insights into certain aspects of the composites industry, particularly the challenges faced by manufacturers, and the strategies embraced by leading companies to overcome these issues. The free report includes some revealing insights into recent market changes and the impact of recent AI technology advancements.

When taking the survey, applicants were assessed on topics including manufacturing challenges and technology adoption, Industry 4.0, sustainability, growth outlook, as well as more general demographic info, to best capture the state of global manufacturing.

Respondents — OEMs and Tier 1s make up the bulk of them — are predominately positioned in aerospace and defense (75%), with automotive (38%) and other (38%) the next two majorities. Most respondents are located either in North America (55%) or Europe (28%).

The survey captured several prevailing trends in global manufacturing. These include the impact of inflation on production costs, labor market challenges and the uncertainty surrounding supply chain stability. Fifty-seven percent of respondents agree that new manufacturing processes and automation is the way forward while 42% think that improving inventory control and material procurement is the solution.

Related to these challenges is the state of digital transformation (e.g., AI, IoT, data analytics). Companies varied — some respondents noted significant progress in leveraging these technologies, while others are still in the early stages of implementation. Specifically, OEMs and Tier 1 segments lead in the digitization level at 20% and 60%, respectively. Tier 2 and Tier 3 are mainly investigating technology and use cases.

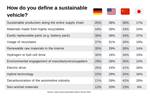

The survey also explored the efforts made by companies to meet sustainability goals, such as reducing carbon emissions, optimizing material use and implementing circular economy practices. Forty-five percent of respondents said they’ve heard about plans to regulate manufacturing processes but don’t feel the pressure of improving sustainability at their facility; 30% note no pressure at all. These sentiments spanned from small to large companies.

When asked for a growth outlook in the next three years, an overwhelming majority expected growth in some forth, particularly in the double digits.

For a more detailed look, survey results can be downloaded for free here.

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

.jpg;maxWidth=300;quality=90)