RATH works with InVECOF project to mature oxide fiber production in Europe for CMC

Producer of Altra ceramic staple fibers aims to scale up continuous Ox fibers to compete with Nextel 610 and 720, and with its partners, offer improved fibers with creep resistance for higher temperature CMC applications.

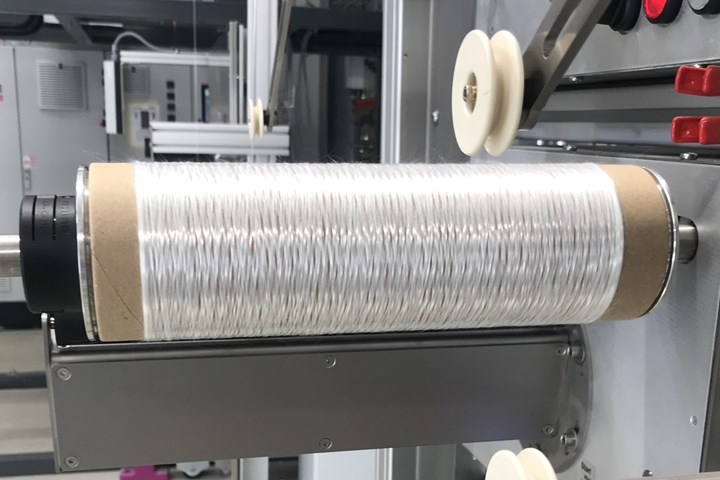

RATH Group (Vienna, Austria) is a supplier of refractory materials for temperatures up to 1,800°C with more than 130 years of experience in the industry. It currently produces Altra short (staple) fibers made from alumina or mullite. Mullite is a mixture of alumina and silica, while corundum (also called α-alumina) is a pure, crystalline form of alumina. Alumina is aluminum oxide (Al2O3) and silica is silicon dioxide (SiO2). Both are used to make oxide (Ox) ceramic fibers, one of the most common reinforcements for ceramic matrix composites (CMC), in addition to silicon carbide (SiC) fibers and carbon fiber. RATH is now completing the development of continuous Ox ceramic fibers and building up production capacity at a new facility in Mönchengladbach, Germany.

Currently, Ox fibers are only available on a large commercial scale from 3M (Minneapolis, Minn., U.S.) via its Nextel 610 (corundum) and 720 (mullite) fibers. However, the industry has long desired to add manufacturers, which should help to expand production and applications for Ox/Ox CMC. According to a presentation by Fraunhofer ISC (Bayreuth, Germany), additional companies currently producing Ox fibers and/or scaling to commercial production include:

- Nitivy (Tokyo, Japan) ALF continuous alumina (Al2O3) fiber

- RATH

- Saint Gobain Advanced Ceramic Composites (Nemours, France and Louisville, Ky., U.S.) in partnership with DITF (Denkendorf, Germany)

- Shandong Dongheng Colloidal Material Co. Ltd.’s (Dongying City, Shandong, China) Afibre

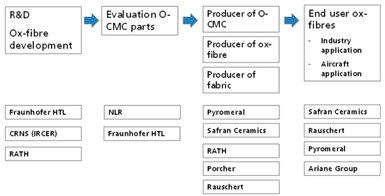

RATH is also a partner in Horizon Europe’s InVECOF project (2022–25) along with the Fraunhofer ISC Center for High Temperature Materials and Design HTL and other leaders in high-temperature materials and applications. Among these are two companies whose work CW has discussed: Pyromeral (Barbery, France) and NLR (Marknesse, Netherlands) via the SuCoHS project.

The specific goals of InVECOF include:

- Implementation and validation of Ox fibers at least equivalent to Nextel 610 and 720 fibers

- Validation and upscaling of improved Ox fibers with increased application temperature and creep resistance 100-200 K higher compared to Nextel 610 and 720 fibers

- Within 4-5 years, production of European-made Ox fibers and O-CMC parts competitive with those produced in the U.S.

CW asked RATH for more details about its planned Ox fiber production.

What types of oxide fibers is Rath developing and when will these be in commercial production?

RATH is developing continuous oxide ceramic fibers, with the aim to offer composites manufacturers alumina and mullite fiber solutions that meet the highest mechanical standards for tensile strength and modulus that also retain their strength at very high temperatures and in corrosive atmospheres. RATH is continuing to build up its capacity to produce larger quantities of continuous fibers by 2025.

Why are these fibers so challenging to manufacture and commercialize?

Multiple processes are involved in the production of continuous oxide ceramic fibers. These include chemical, spinning and thermal processes. They all are interdependent and lead to oxide ceramic fibers of the highest quality within very narrow process windows. RATH is already successfully producing polycrystalline oxide ceramic staple fibers (Altra) in an equally sophisticated process. These products are used in thermal insulation up to 1,800°C and we will use our knowledge as a leading manufacturer of refractory fibers to develop continuous oxide ceramic fibers that can be used at even higher temperatures than is currently possible.

What research/technology developments are vital for more widespread adoption of oxide fiber CMC?

The key factor for the progress of O-CMC development is the reliable supply of fibers. Multiple international sources of high-quality continuous oxide ceramic fibers will enable O-CMC manufacturers to invest more in this technology and provide solutions for various industries (aerospace, chemical industry). Another major innovation step would be an oxide ceramic fiber with a higher creep resistance than is currently available, leading to a higher application temperature.

As explained in the company’s press release earlier this year, the first components using RATH continuous Ox fibers have already been manufactured. RATH is committed to its planned Ox fiber commercialization because broad use of high-tech CMC materials promises to make the energy transition more efficient and more ecological, says Christopher Kluthe, responsible for ceramic continuous fibers for the RATH Group. “Wherever lightweight design meets high temperatures, we need CMC,” adds Kluthe. “And fiber composite ceramics are based on the broad market availability of oxide ceramic fibers. Only in this way will these technologies be able to make their contribution to the energy transition.”

Related Content

ORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreGE Aerospace awarded demonstration contract for NASA HyTEC project

Turbofan engine small core technology development with CMC-coated components targets enhanced fuel efficiency in single-aisle aircraft by mid-2030s.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreRead Next

Lucideon, NCC partner to develop next-gen CMC solutions

This close collaboration will develop, analyze and evaluate advanced materials and applications to support the emerging demand for materials that can survive high-temperature, extreme and harsh environments.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More