Robot Extruder offers low-investment alternative to explore composites additive manufacturing

CEAD extruder mounts to robotic arm or gantry systems, already in use to print molds for large composite structures.

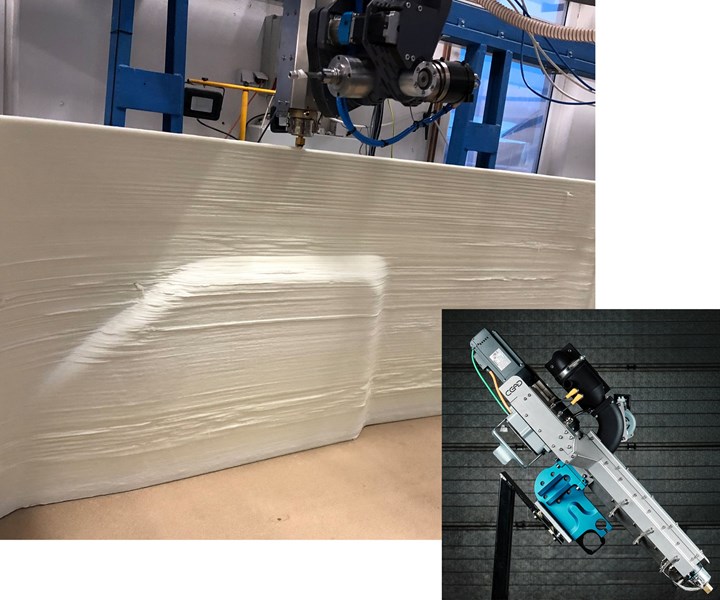

CEAD Robot Extruder mounted onto a CNC machining system gantry at Rapid Prototype (Budapest, Hungary) printing molds used to produce a customized composite sleeper cab for a heavy-duty truck. SOURCE: Rapid Prototype, CEAD.

CEAD (Delft, Netherlands) has commercialized the CFAM Prime system for large-scale 3D printing of composites, using a patented print head, which can reinforce thermoplastics with both continuous and short fiber in the same part. Even as Dutch composites producer Poly Products (Werkendam, Netherlands) explains its investment into this system in the article, “Think big, print bigger” in the current issue of Kunststof Magazine, CEAD recognizes that other companies require a different approach.

“We see demand for large scale 3D printing is growing,” explains CEAD head of business development Charléne van Wingerden. “But not every company has space for a large installation like our CFAM system due to its footprint of 8 by 4 by 4.5 meters.” However, because many companies already have robotic arms or gantry systems (e.g., CNC machining), CEAD has developed a standalone extruder that can be integrated into such systems, thus offering a lowered-investment solution to explore the possibilities within additive manufacturing.

“We were building molds using CNC machined polyurethane foam and hand layup GRP (glass fiber-reinforced plastic), but that approach involved too much labor and waste,” explains György Juhász, owner of Rapid Prototyping (Budapest, Hungary) which bought a CEAD Robot Extruder in December. “We are now 3D printing molds using 30% short glass fiber-reinforced polypropylene and cutting our labor time by 50%.”

The CEAD Robot Extruder is designed to be a lightweight solution with a high output for large-scale 3D printing composites. This system is delivered with everything needed for 3D printing: the Robot Extruder, Siemens PLC-based control, material storage, material transport, watercooling and an easy to install extruder mounting bracket.

Highly-filled polymers and range of thermoplastics

The CEAD Robot Extruder is a custom-designed, high-temperature system dedicated for 3D printing. Using four heat zones, the extruder gradually melts neat or reinforced thermoplastic pellets. It is powered by a Siemens servo motor and a planetary gearbox for higher torques required to process certain materials. The Robot Extruder is engineered to reach temperatures of 330°C by default or up to 400°C for the high-temperature version, which makes it possible to extrude a wide range of fiber-reinforced thermoplastic materials — even PEEK (polyetheretherketone).

The upgrade to a 1-kilowatt servo motor gives a standard torque of 63 Nm and a peak torque of 144 Nm, beneficial for printing difficult and tough materials at high output. Using engineering-grade materials can push an extruder to its maximum capabilities, for example Arnite 50% glass fiber-reinforced PET (polyethylene terephthalate) and carbon filled PESU (polyethersulfone). Though the standard servo motor is capable of processing these materials, the upgrade gives a bit more output, if needed.

Material storage and transport

The Robot Extruder includes storage for up to 25 kilograms of material that doesn’t need to be dried thoroughly. For material that does need to dried, the material transport pump is located underneath the storage and can be directly linked with an external dryer. The material transport pump blows dried material into the extruder hopper, a process that is fine-tuned through Siemens controls.

Because the Robot Extruder is being delivered as a complete package, the material transportation unit is included. A lot of research has gone into developing a reliable material transportation system, because it is critical for printing during long periods unattended or when printing with expensive engineering-grade materials. “We consider it unacceptable to have a printing failure because the transportation system failed,” says Wingerden. “CEAD is unique in the fact that the transportation unit is a standard component shipped with the extruder.”

Easy integration and control

The whole system is operated through a Siemens touch screen, which runs CEAD software, specifically designed for the Robot Extruder and CFAM systems, based on years of experience in plastics extrusion, 3D printing and machine development.

All Robot Extruder components work together for a fully integrated system. The operator interacts with the Siemens control panel, which can be connected to the robot or gantry system. The Robot extruder is controlled by only two signals — analog 0-10 volt and digital 0-24 volt direct current (dc) — offering a robust system for the robotic arm or gantry to control the extruder. Recently, CEAD introduced control of the Robot Extruder over Profinet, allowing for more advanced integration options.

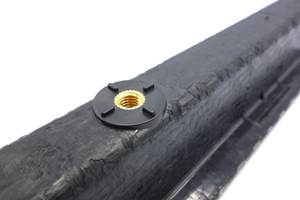

A custom mounting bracket is also included, requiring only a few bolts to mount the Robot Extruder onto a robotic arm or gantry.

Ancillary systems

CEAD also offers an easy-to-integrate drying system and other components, such as nozzle sets. Rapid Prototyping bought a dryer in addition to its Robot Extruder. “So, we can print with a range of materials, for example, PET, PET-G and ABS,” says Juhász.

Related Content

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More