SGL Carbon and Elbe Flugzeugwerke extend contract

SGL Carbon will continue supplying carbon fiber prepregs for the Airbus A350 cabin’s floor panels until the end of 2020.

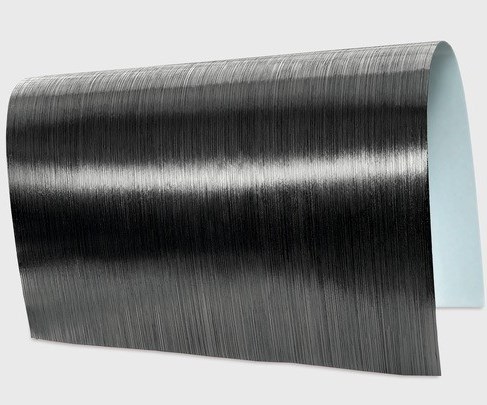

Carbon fiber prepreg for Airbus A350 floor panels. Source | SGL Carbon

SGL Carbon (Wiesbaden, Germany) has extended its contract with aircraft manufacturer Elbe Flugzeugwerke (Dresden, Germany), a long-established German aircraft manufacturer, and will continue supplying prepregs for use in the Airbus A350 cabin’s floor panels until the end of 2020.

SGL Carbon says it has been supplying Elbe Flugzeugwerke with carbon fiber prepregs for the floor panels since the A350 was first launched. The panels are produced in a sandwiched technology using several prepreg layers. The composites used must be safe and reliable under extreme conditions; thus, SGL says its the material it produces for the project is highly flame-resistant and complies with the aerospace industry’s fire protection regulations for interiors. The material’s reported low weight and high strength and rigidity suit it for the lightweight construction required by the aerospace industry.

The materials are produced at the SGL Carbon site in Willich, near Düsseldorf, which specializes in producing carbon fiber and glass fiber prepregs, particularly for the aerospace industry.

“We are delighted to be signing this contract with a long-standing customer, thereby further strengthening a constructive working relationship based on trust,” says Dr. Andreas Erber, head of the aerospace segment of the business unit composites – fibers & materials at SGL Carbon. “The extension of the contract also underscores our expertise regarding the technology and materials involved in the aerospace sector.”

Related Content

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;width=70;height=70;mode=crop)