Skoltech optimizes pultrusion process productivity

The institute analyzed the influence of pulling speed on the structural characteristics of L-shaped profiles, analyzing the interconnection between a variety of characteristics.

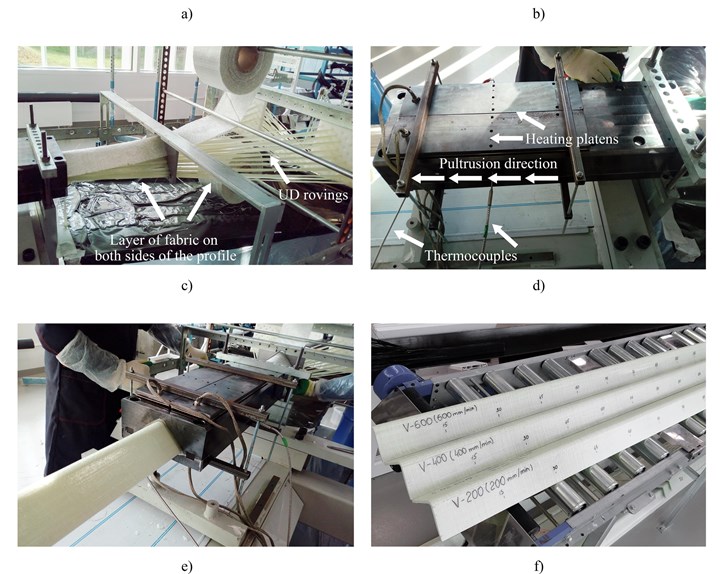

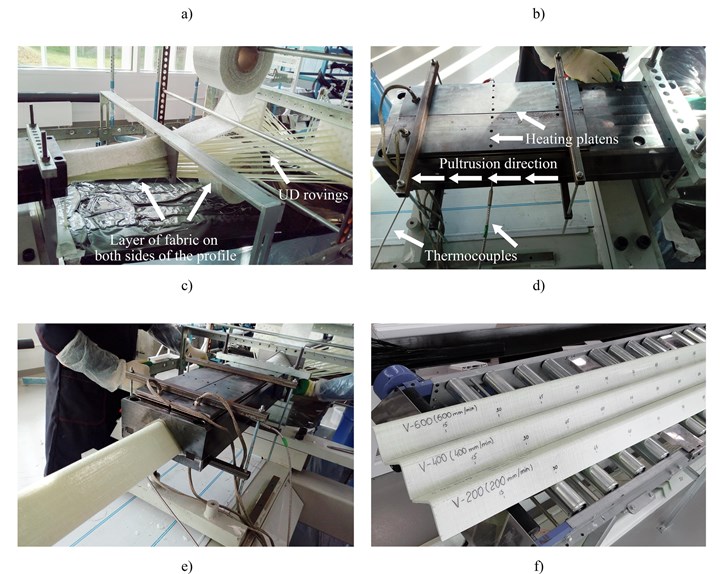

Photo Credit: Skoltech

A group of scientists from the Skoltech Center for Design, Manufacturing and Materials (CDMM, Moscow, Russia) and University of Salerno (Italy) have reportedly improved pultrusion process productivity by optimizing pulling speed and structural parameters. According to the research results, which were published in the Composites Structures journal, Skoltech discovered and analyzed the interconnection between pulling speed of pultrusion and severity of manufactured induced shape distortions, matrix cracking and delaminations, as well as mechanical characteristics.

Out of the many current composite manufacturing processes, Skoltech says, pultrusion is considerably the most efficient, combining high production rates with low material waste, characteristics that are continuously sought after, particularly in the construction market.

The pultrusion process optimization involves careful consideration of the many parameters influencing the quality of the final product, the institute adds. One of the parameters to be considered is the pulling speed. Maximizing the pulling speed while preserving the quality of the produced profiles is necessary to increase efficiency and, thus, the pultrusion process's profitability.

This study analyzed the influence of pulling speed on the structural characteristics of pultruded glass fiber/epoxy-vinyl resin 75 × 75 × 6-millimeter L-shaped profiles. The profiles were pultruded at three pulling speeds: 200, 400, and 600 millimeters per minute. After fabrication, the spring-in values of the fabricated profiles were measured; the profiles were examined under a microscope to identify and study their cracking; and the mechanical properties of the pultruded composite were determined. The spring-in was measured immediately after fabrication and then at intervals of two to three days over a 90-day period.

From its research, the team says it has found optimal pulling speed, and identified its influence on the structural parameters of the produced profiles. In particular, mechanical properties, delaminations and cracking behavior and manufacturing-induced shape distortions were analyzed.

The obtained outcomes are said to open doors, not only to the improvement of the manufacturing process, but also to the development of a mathematical model able to predict the linear elastic and viscoelastic behavior of profiles both at manufacturing and storage stages.

“The research results are of great importance since previous studies were analyzing structural parameters separately from each other. Thus, their interrelations were not accounted for when discussing the pulling speed's influence on structural characteristics of the pultruded profiles fabricated at different pulling speeds. The current study successfully filled this gap,” adds the first author of the study, Skoltech PhD student Aleksander Vedernikov.

The university’s developments also laid the foundations for Anisoprint (Esch-sur-Alzette, Luxembourg) one of a growing number of technology companies advancing 3D printing of composites with continuous fiber, which was founded in 2014 by CEO Fedor Antonov. Prior to the company’s founding, Antonov was working to build Skoltech’s new center for composites technology.

Related Content

-

Creative Composites Group introduces H-5 rated FRP bridge decking

High-strength pultruded SuperDeck Lite gives ambulances and maintenance vehicles access to trails, bridges, boardwalks and sidewalks

-

FST-rated thermoset resin with rapid, tunable cure is designed for infusion

CAMX 2023: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

-

TNL Applied Composites Manufacturing course begins February 2023

Hybrid, seven-session class helps participants learn the tricks of different composites manufacturing technologies from wet layup to pultrusion.