FST-rated thermoset resin with rapid, tunable cure is designed for infusion

CAMX 2023: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

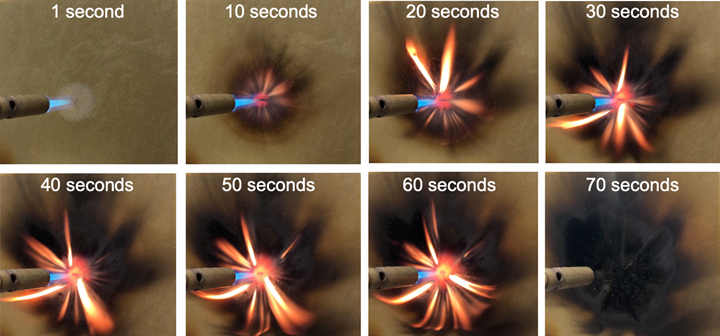

Trimer Technologies (Plymouth, Mich., U.S.) has developed Harp Rapid, a low-cost, nonhalogenated and styrene-free thermosetting resin for resin infusion processes, which can greatly exceed the fire, smoke and toxicity (FST) rating for aircraft interiors defined in FAR 25.853, while featuring a V0 and Class A E84 rating. Moreover, Harp Rapid offers a fast, tunable cure profile; the novel resin system can cure in as little as 30s at 250ºF, achieve a Tg >700ºF and is said to attain mechanical properties equivalent to the highest performance polymers used in the aerospace industry.

Trimer says it has developed the technology required to control the resin system’s latency such that the reactivity can be tailored to provide a designed working life and cure rate. While the company’s fastest resin cure is achieved in as little as 30s, this system provides a 1-hour working life, enabling the infusion of large structures. Specifically, the resin is designed as a low-viscosity infusion resin that can be processed through resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM) or casting processes, providing significant cycle time reduction compared to existing state-of-the-art materials. For instance, Trimer has demonstrated a cure cycle that is eight times faster than current state-of-the-art resins used in Ford’s F150 fiberglass leaf spring.

The company has also developed internal mold releases that enable the manufacture of fire-resistant pultrusions. Traditional FST-rated pultrusion resins either require bromination or use phenolics which produce low-quality and low-strength pultrusions. Alternatively, Trimer’s Rapid resin system can enable pultruded composites with a short beam strength over 10 ksi while producing better fire behavior than phenolics. In addition to the high strength and FST properties, the Harp Rapid resin system offers pull speeds as high as 10 ft/min for efficient manufacturing. Trimer has also developed resin systems compatible with either die injection or bath pultrusion to fit any pultrusion line.

Related Content

-

Ballistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.