Solvay, NIAR announce partnership to advance future aviation solutions

Solvay scientists and engineers will be embedded within NIAR’s ATLAS facility, providing material guidance and support on a variety of known and future aerospace manufacturing applications.

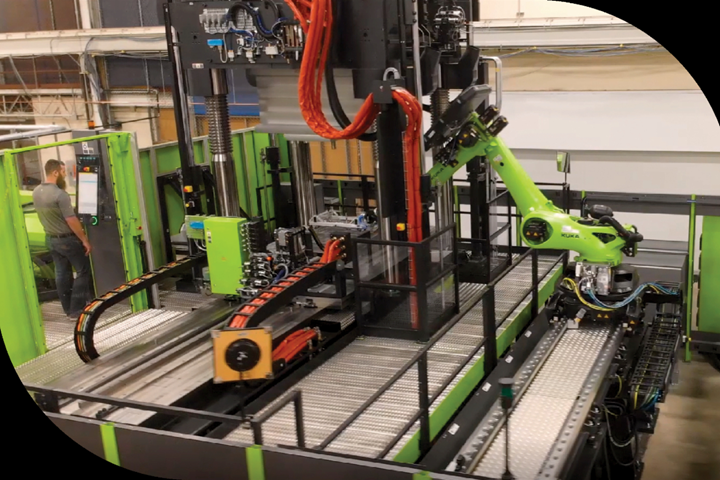

Photo Credit: WSU-NIAR

Today, Solvay (Brussels, Belgium and Alpharetta, Ga., U.S.) and Wichita State University’s (WSU) National Institute for Aviation Research (NIAR) have announced a partnership on research and materials development at NIAR’s facilities in Wichita, Kansas. The partnership is aimed at developing future solutions to bolster the aviation industry and create opportunities for companies of all sizes to revolutionize the future of flight.

“Solvay is excited to work with NIAR and Wichita State University to take the aerospace industry to new heights,” says Carmelo Lo Faro, president of Solvay Materials Segment and board member of the Aerospace Industries Assn. (Arlington County, Va., U.S.). “This partnership provides Solvay with access to the invaluable facilities and prototyping capabilities of NIAR’s research and development [R&D] centers while helping our business partners realize new applications of our materials that can improve performance and sustainability.”

Scientists and engineers at Solvay will be embedded within NIAR’s Advanced Technologies Lab for Aerospace Systems (ATLAS), a multi-disciplinary manufacturing environment and engineering education program that helps prepare engineers and educators for the Factory of the Future and aid the current workforce in seamlessly adapting to advancements in the workplace. ATLAS includes more than 150,000 square feet of space dedicated to developing prototypes, testing the durability and strength of aviation components and partnering with aerospace OEMs to discover creative solutions that can improve their aircraft. Automated thermoplastic welding and tape slitting, as well as an installed Samba Pro Prepreg system are some of the equipment ATLAS has available.

“We’re thrilled to have Solvay on site to provide material guidance and support on a variety of aerospace manufacturing applications,” adds John Tomblin, WSU senior vice president for industry and defense programs, and NIAR executive director, ATLAS director and senior research scientist in composites and structures at NIAR. “Solvay scientists work closely with our researchers to exchange ideas and results. We get guidance and material support, while Solvay also connects us with leading players in the aerospace industry to foster future collaboration.”

Work has already begun between Solvay, NIAR and customers. Through this partnership, NIAR and Solvay will develop applications for a wide variety of aerospace verticals, including commercial aircraft, defense, urban air mobility (UAM) and many more applications — both known and not yet imagined. Solvay’s strategic involvement with NIAR furthers its commitment to expanding its broad portfolio in the aerospace industry, from composite materials, adhesives, surfacing films and specialty polymers for fixed-wing aircraft, rotorcraft, propulsion and systems, space and launch and UAM applications.

NIAR and Solvay will host an opening ceremony later this year.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.