Suprem SA begins new pultrusion line production

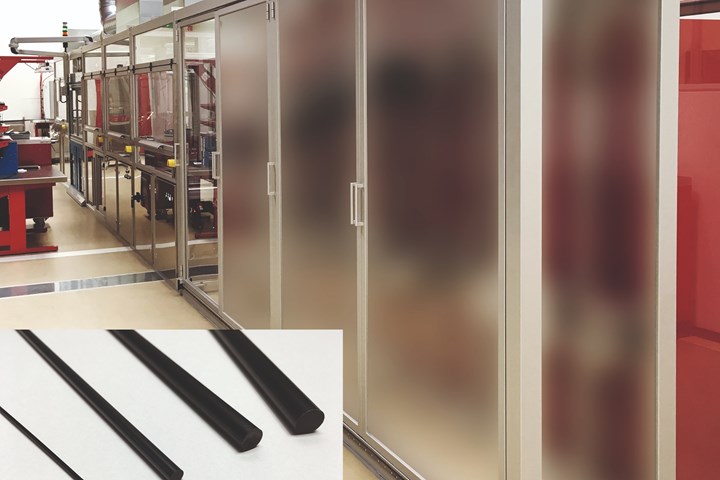

Highly automated manufacturing line processes continuous fibers with high-performance thermoplastics for tapes, profiles and rods.

Photo Credit: Suprem SA

Suprem SA (Yverdon-les-Bain, Switzerland) reported on Jan. 25 that it is leveraging its decades of thermoplastic composite materials into a new pultrusion line.

The company says the advanced machinery enables the combining of continuous fibers (carbon, glass and aramid fibers) with high-performance thermoplastics (PA to PAEKs) into rods and profiles.

The pultrusion line and its dedicated production hall are said to fulfill stringent requirements in terms of cleanliness, manufacturing process validation and quality control. Both assets are qualified for medical applications and can be used for other demanding markets, Suprem SA says.

Together, with current production equipment, innovative and customized products such as tape, profiles and rods can also be offered for automated additive manufacturing processes.

“After several years of development, I am proud of the team, which has mastered a technological breakthrough with a highly automated manufacturing line,” says Dr. Anatole Guilliot, CEO, Suprem SA. “It is an important milestone and a commitment to our customers to maintain the quality benchmark on thermoplastic composite material market. We are looking forward to further supporting our customer’s projects with high quality and reliable products for automated processing.”

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

.jpg;maxWidth=300;quality=90)