Teton Composites launches analysis business

US-based Teton’s FEA service business specializes in helping clients design and analyze complex composite structures.

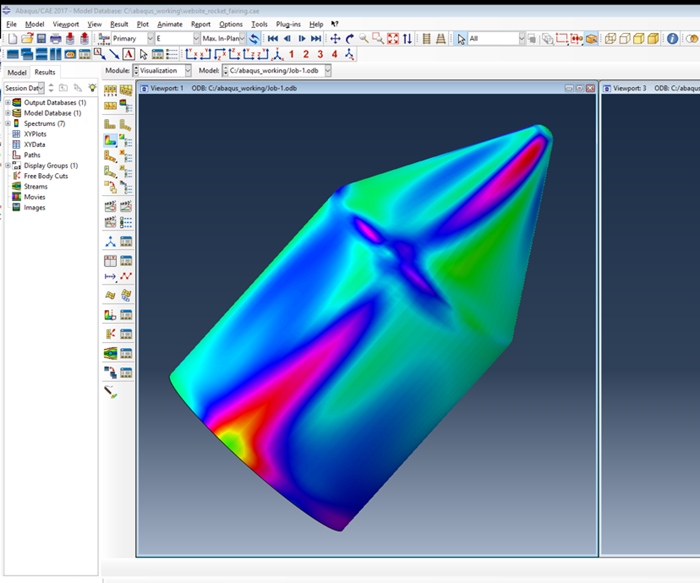

Teton Composites (Laramie, WY, US) announced on Dec. 13 the formation of its finite element analysis (FEA) service business. The business specializes in helping clients design and analyze complex composite structures, providing fundamental baseline designs while also reducing expensive iterations between design and testing.

“We’re building a highly skilled technical team that will have the capacity to analyze both continuous and chopped fiber filled structures,” says Rick Dalgarno, director of analysis services at Teton Composites. “This unique simulation capability is very specialized and very necessary. It is critical that a company developing a composite component fully understand performance before manufacturing.”

The real challenge with any industry’s adoption of composites is how best to design structures to minimize material while maximizing performance. Teton is working on an advanced stress analysis tool for evaluating structural integrity of as-manufactured parts made by additive manufacturing. The National Science Foundation (NSF) is currently funding the development. Teton Composites expects to release its first software product in late 2018.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.