Toray Advanced Composites expands thermoplastic composites capabilities

High-heat laminate press enables consolidation of Toray Cetex reinforced thermoplastic composite laminates up to 400°C and produces 50% larger laminates for large-part geometry capabilities.

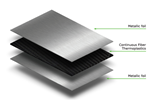

Toray Advanced Composites’ high-heat laminate press. Photo Credit: Toray Advanced Composites.

On May 19 Toray Advanced Composites (Morgan Hill, Calif., U.S. and Nijverdal, the Netherlands) announced the expansion of its thermoplastic composite material capabilities for high-performance applications, with the introduction of a next-generation, high-heat laminate press at the company’s Nijverdal facility in the Netherlands.

This expansion in capability advances the supply of Toray Cetex reinforced thermoplastic composite laminates (organosheets) for high-temperature performance applications across resin systems including PEEK, PEKK and LMPAEK. Toray says the press can consolidate up to 400°C. Laminates are available with woven fabric, uni-directional (UD) and hybrid reinforcement configurations.

Further, laminates made using the high-temperature press are reported to be 50% larger than existing laminates in this performance category. According to the company, the increased size broadens the adoption of high-performance thermoplastic composite materials to include larger part geometries across both aerospace and industrial applications.

Toray Cetex laminates are fully consolidated in the press, eliminating the need for secondary layup and consolidation stages, and enabling efficient and cost-effective high-volume fabrication of high-performance, high-quality thermoplastic composite parts. The laminates also undergo rigorous quality inspection to ensure near-zero voids.

“This announcement is an exciting step in our strategic expansion of thermoplastic technology,” says Frank Meurs, managing director of Toray Advanced Composites. “Building on over 30 years of heritage and innovation within our Cetex thermoplastics, this unique capability underlines our continuing commitment to invest in the future needs of large-scale adoption of thermoplastic composites in an affordable way.”

As with existing Toray Cetex reinforced thermoplastic laminates, ply orientation, thickness and reinforcement can be customized to end-user specifications. Additional functionality, such as anti-galvanic corrosion and lightning strike protection, can also be integrated into the laminate at the point of consolidation for further processing and performance benefits.

Related Content

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

.jpg;maxWidth=300;quality=90)