Manna Laminates FEATURE organosheet laminate targets EMS applications

Fiber-metal laminate (FML) can be thermoformed in the injection or compression mold, possesses ideal characteristics for electric vehicle applications.

Photo Credit: Manna Laminates

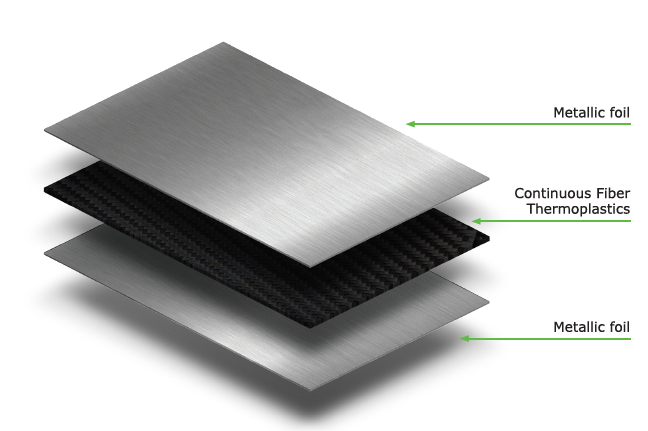

Manna Laminates (Misgav, Israel) introduces its new organosheet FEATURE (Flame retardant, Electro-magnetic shielding, Appearance and acoustics, Thermal conductivity, Underweight, Robustness and Economical) FML (fiber-metal laminate) semi-raw material, a laminate with integrated metal-sheet layers which can be located on the outer side of the laminate or between the reinforcement fabrics layers (usually glass or carbon fiber).

FEATURE FLM is part of Manna’s Formtex continuous fiber thermoplastics (CFT) family of products, which are made using advanced woven fabric-based organosheet or layered unidirectional (UD) tape. According to the company, the laminates can be customized per part or industry requirement, making them ideal for quasi-isotropic-loaded hybrid parts. The result is said to be an innovative, affordable material that boasts outstanding quality and performance capabilities.

The FEATURE organosheet semi-raw material is also said to be a good candidate for use in electric vehicle (EV) battery casings — including upper and lower parts — as well as electrical boxes, applications which require EMI shielding, flame retardant properties (meeting UL-94 standard), thermal conductivity, high energy absorption, robustness and low weight. FEATURE materials can be also used for typical car body parts such as cross members, longitudinal beams, wheel brackets and other components.

Moreover, says Manna Laminates, the metal foil can be integrated into the laminate during the organosheet manufacturing process, unlike other organosheet manufacturing processes which call for a second lamination step of the foil to the plastic substrate.

Further, Manna’s FEATURE laminate can be thermoformed in the injection or compression mold, a feature that ensures only one part and forming process is needed, compared to forming the organosheet and the metal foil separately and attaching together before final assembly. This is also applicable for complex geometries.

Using its innovative impregnation and consolidation process, Manna adds that it can manufacture thick laminates of up to 10 mm in a single step with shorter thermal history and superior mechanical and delamination resistance properties.

FEATURE organosheet material is available in a wide range of fiber/resin combinations and product formats. Fiber materials include E-glass and carbon fiber, and resin materials include PP, PA6, HDPE, LDPE, PC and more. It can be supplied as a rectangular-cut laminate or cut to shape.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.