Toray Industries develops innovative separation membrane incorporating porous carbon fiber

Independent carbon fiber support and separation layers enhance CO2 permeability and durability, with prospects in hydrogen production, as well as gas separation and purification applications.

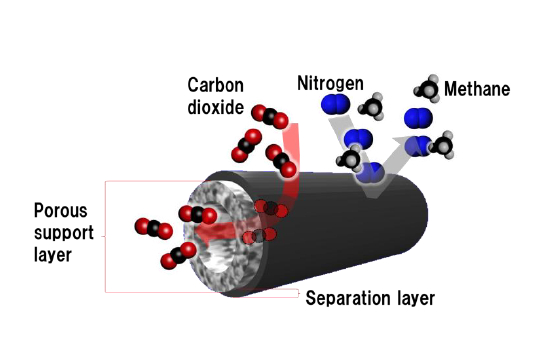

CO2 separation membrane structure. Photo Credit: Toray Industries Inc.

Toray Industries Inc. (Tokyo, Japan) reports that it has developed a carbon dioxide (CO2) separation membrane with a dual all-carbon fiber structure. This comprises a hollow/porous carbon fiber as a support and a thin carbon fiber membrane separation layer on the surface. Said to offer optimized CO2 separation performance and high durability, Toray says the membrane is better suited for making facilities more compact compared to conventional inorganic separation membranes. The company expected to step up research and development to deploy this separation membrane in social infrastructure.

According to Toray Industries, CO2 separation technology is vital to using CO2 to help materialize a circular carbon economy. While this technology commonly employs absorption- and adsorption-based facilities, the company says, issues arise with such setups because they consume too much energy. As a result, this situation fueled worldwide research into energy-efficient membrane separation techniques.

Separation layers with pores smaller than one nanometer are said to offer better gas permeability because they are thinner, but the lower pressure resistance necessitates combining with a support layer. Regular inorganic support layers are hard and brittle, and the diameters cannot be reduced, preventing dense module packing and miniaturization.

Toray created a porous carbon fiber with a continuous pore structure in 2019 (see “Porous carbon fiber: Permeable, adsorptive and conductive”), which is able to provide a support layer for gas separation membranes that offer excellent gas permeability and chemical and heat resistance by creating a hollow fiber. The company’s new CO2 separation membrane employs a thin, hollow-fiber porous carbon fiber with a diameter of less than 300 micrometers as a support layer. On the surface is a uniform carbon film separation layer just a few micrometers thick.

With the support and separation layers independent, this separation membrane reportedly enhances CO2 separation and durability. Its thin, flexible membrane enables continuous production, similar to regular fibers, and its high density packing capabilities enable module miniaturization. With this innovation, Toray reports that CO2 permeability can be five times greater than that of conventional inorganic CO2 separation membrane modules with the same volume.

One prospective use for Toray’s new separation membrane is natural gas and biogas purification. According to the company, it could also serve in hydrogen production and purification, exhaust gas CO2 separation and other gas separation applications by taking advantage of the selectivity of functional layers according to the gases that need to be separated.

Toray also plans to draw on the innovation hub capabilities of the R&D Innovation Center for the Future at its Shiga Plant in Japan, where it will continue to pursue strategic open innovation and commercialize more advanced gas separation membranes.