Toyota and Hino agree to develop heavy-duty fuel cell truck using composite storage tanks

Type IV tanks will help provide 600-kilometer range and meet commercial vehicle requirements

Share

SOURCE | Toyota Motor Corporation

Toyota Motor Corporation (Toyota City, Japan) and Hino Motors, Ltd. (Hino, Japan) have agreed to jointly develop a heavy-duty fuel cell truck, and to proceed with initiatives toward its practical use including verification tests.

The heavy-duty fuel cell truck in this joint development project is based on the Hino Profia and will take maximum advantage of the technologies that Toyota and Hino have developed. The chassis is designed with optimum packaging for a fuel cell vehicle, and steps are being taken through comprehensive weight reduction to ensure a sufficient load capacity. The powertrain comprises two Toyota fuel cell stacks newly developed by Toyota and combined with vehicle driving control that applies heavy-duty hybrid vehicle technologies developed by Hino. Cruising range will be roughly 600 kilometers to meet high standards in both environmental performance and practicality as a commercial vehicle.

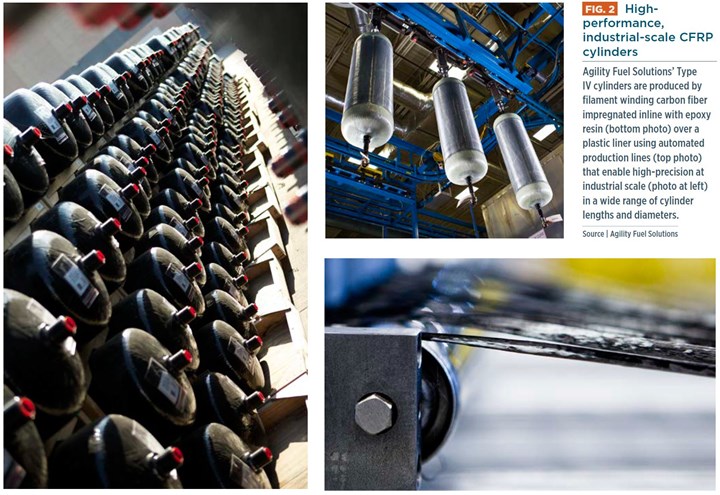

The Class 8 trucks Toyota is developing in the U.S.-based Portal Project also use two Toyota fuel cells as well as four 700 bar (70 MPa) Type IV hydrogen storage tanks made using composites to power a Kenworth T660 truck. The composite tanks were developed and manufactured by Hexagon Composites ASA (Alesund, Norway) and its subsidiary Agility Fuel Solutions (Costa Mesa, Calif., U.S.). Five of the 10 trucks planned in this project have been built and are in testing.

Hexagon Composites (Aalesund, Norway) subsidiary Agility Fuel Solutions (Costa Mesa, Calif., U.S.) produces Type IV composite storage tanks used in hydrogen fuel cell vehicles and supplied such tanks to Toyota for its Portal Project using Kenworth T660 heavy-duty trucks.

SOURCE | “Plant Tour: Agility Fuel Solutions ...”

Toyota and Hino have declared ambitious goals to reduce CO2 emissions by 2050 — 90% reduction from new vehicles compared to Toyota’s 2010 levels and Hino’s 2013 levels. To achieve these reductions, major improvements will be required in the environmental performance of heavy-duty trucks, which account for about 60% of the total CO2 emissions from commercial vehicles (gross weight > 3.5 tons) in Japan.

For the electrification of commercial vehicles, an optimum powertrain must be adopted to ensure both outstanding environmental performance and practicality. Heavy-duty trucks are typically used for highway transportation; therefore, they are required to have sufficient cruising range and load capacity as well as fast refueling capability.

Toyota and Hino have positioned hydrogen as an important energy source for the future and have worked together on developing technologies and innovating fuel cell vehicles for over fifteen years since their joint demonstration trials of the fuel cell bus in 2003. Going forward, Toyota and Hino will further strengthen its partnership and accelerate efforts toward the realization of a hydrogen society.

Related Content

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

.jpg;maxWidth=300;quality=90)