U.K. team successfully recycles reclaimed continuous carbon fibers from pressure tanks

The U.K.’s NCC with partners B&M Longworth and Cygnet Texkimp achieve continuous carbon fiber recovery in a significant first step to deliver sustainable composite pressure vessels for the hydrogen market.

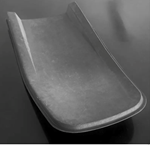

Engineers at the National Composites Centre (Bristol, U.K.), the U.K.’s center of excellence for advanced composite applications, along with British SME partners B&M Longworth (Edgworth, U.K.) and Cygnet Texkimp (Northwich, Cheshire, U.K.), have successfully reclaimed continuous carbon fibers from a whole pressure vessel and re-used them to manufacture a new pressure vessel. This is reported to be the first time this process has been achieved in the U.K. and represents a significant milestone in the development of Britain’s hydrogen capability.

As hydrogen has low energy density, the NCC says, it needs to be compressed and stored at very high pressures, between 350-700 bar (5,076-10,152 psi). This makes high-strength, lower-weight carbon fiber the material of choice, especially for hydrogen pressure vessels in vehicles such as cars or aircraft, where power-to-weight is critical. Demand for carbon fiber, however, is expected to grow five-fold between 2025 and 2030, exceeding global manufacturing capacity. Creating viable, low-cost recovery processes, that retain the inherent strength of continuous carbon fibers for recycling, is therefore key to the development of the hydrogen economy.

According to the NCC, until recently, recycling processes for composite components such as aircraft wings and wind turbine blades has resulted in short fibers with lower mechanical properties than virgin fiber. While there are applications for this material, it is not suitable for re-use in high performing products.

Partnering with B&M Longworth, the NCC team successfully reclaimed continuous carbon fiber from end-of-life (EOL) composite pressure tanks, using the company’s revolutionary DEECOM process (see “Pressurized steam-based composites recycling for full fiber reclamation”). Originally designed to remove waste polymers from filters and production equipment, the process uses superheated steam, under compression, to penetrate microscopic fissures in the composite’s polymer, where it then condenses. On decompression, it boils and expands, cracking the polymer and carrying away broken particles. This pressure swing cycle is then repeated until all the matrix (the material suspended in the polymer) has been separated from the fiber, enabling the monomers to also be reclaimed for possible reprocessing.

“Not only does this technology have the potential to transform EOL outcomes for composites, but it also shows how we can do so without compromising the essential properties of the fiber.”

Crucially, the NCC says, the DEECOM process leaves the primary component material intact and undamaged, enabling for any length to be retained. As a result, NCC engineers working with Cygnet Texkimp, could use the reclaimed continuous carbon fiber to make a new pressure vessel using filament winding.

The partnership is now looking to work with manufacturers to scale and industrialize this process, sharing the knowledge of recent recycling trials. The next step is to undertake fiber characterization analysis of the reclaimed material and recycled vessel, as the team works towards their ultimate goal: developing the disruptive technologies that enable sustainable hydrogen storage solutions.

“Achieving continuous fiber recovery is a significant step towards our goal of a fully recyclable certified tank — the critical technology barrier we need to address, if we are to embed hydrogen in our energy mix and meet net-zero targets,” Marcus Walls-Bruck, chief engineer, hydrogen, NCC says. The project results will be announced at JEC World this week. “We are at the stage of being able to share this expertise in fiber recovery and our extensive design exploration work for composite pressure vessels. We want to hear from companies interested in joining us on this journey to sustainable pressure vessels as we accelerate U.K. capabilities.”

The fiber recovery and recycling project forms part of the NCC’s hydrogen program, developing and sharing the technical knowledge, cross-sector composite expertise and state-of-the-art technology that businesses need to achieve their hydrogen ambitions.

As part of this program, NCC engineers have worked to refine composite pressure vessel designs, producing detailed design and analysis to minimize waste and trial the tools and manufacturing processes industry will use to reclaim and recycle continuous carbon fibers. They have also reportedly delivered composite design specification for cryogenic pressure vessels and are working on a certification pathway for composite pressure pipes, including those to be used offshore.

“Following intensive R&D into the use of DEECOM for composite reclamation and circularity, we’re excited to see successful reclamation and remanufacture of a pressure tank,” Jen Hill, director, B&M Longworth Ltd., says. “Recent projects have seen success in a range of composite panels and automotive parts, so a move towards hydrogen tanks was the next logical challenge. Thanks to insight from experts at the National Composites Centre, along with the expertise of our partners at Cygnet Texkimp, we’ve achieved what several said was impossible and are already progressing to the testing stage and looking for the next challenge.”

“One of the most exciting aspects of this collaboration and the technologies it is built around is the way in which we are able to maximize the value and integrity of the fiber at every stage in the process,” Luke Vardy, CEO, Cygnet Texkimp adds. “Not only does this technology have the potential to transform EOL outcomes for composites, but it also shows how we can do so without compromising the essential properties of the fiber. That commitment to fiber integrity is significant because it allows us to reclaim and repurpose carbon fiber in a way that is reliable and sustainable, while creating end products of the highest quality and consistency.”

Visit the NCC at JEC World in hall 6, booth R52 to see the recycled pressure vessel using reclaimed continuous carbon fiber, learn more about the innovation project and find out how the U.K.’s NCC can help you accelerate your composites for hydrogen ambitions.

Related Content

Drag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Cecence, NCC and Gen 2 Carbon develop sustainable airplane seatback

Conducted life cycle analyses found significant benefits using recycled carbon fiber, with an 84% reduction in carbon emissions.

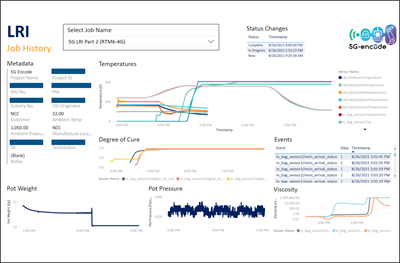

Read MoreNCC and Synthesites work toward intelligent manufacturing for resin infused composites

The National Composites Centre (NCC) and Synthesites develop an advanced closed loop control system for resin infusion with non-invasive sensors, real-time resin flow monitoring and accurate, in-situ estimation of online viscosity and glass transition temperature.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)