NCC and Synthesites work toward intelligent manufacturing for resin infused composites

The National Composites Centre (NCC) and Synthesites develop an advanced closed loop control system for resin infusion with non-invasive sensors, real-time resin flow monitoring and accurate, in-situ estimation of online viscosity and glass transition temperature.

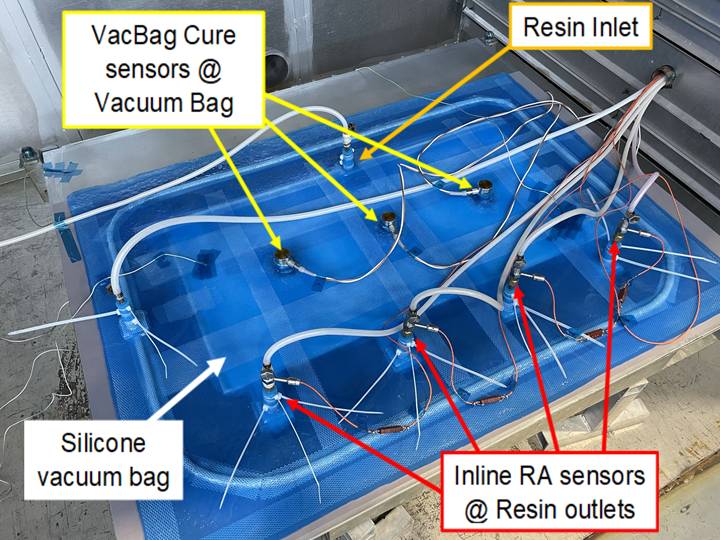

RA sensors monitor resin arrival while Vacbag Cure sensors monitor resin viscosity and Tg of the infused preform through the vacuum bag, based on resin dielectric and temperature measurements. Photo Credit: National Composites Centre (NCC), Synthesites

The National Composites Centre (NCC, Bristol, U.K.) has worked with dielectric cure monitoring technology supplier Synthesites (Uccle, Belgium) since 2015. In the 5G-ENCODE (ENabling COnnectivity for Digital Engineering), these two partners have demonstrated a fully operational, closed-loop resin monitoring and control system for advanced manufacturing of carbon fiber-reinforced polymers (CFRP) and other composites by liquid resin infusion (LRI) processes. The system enables non-invasive, real-time tracking of the resin flow, viscosity and glass transition temperature (Tg), as well as automated control of outlet valves.

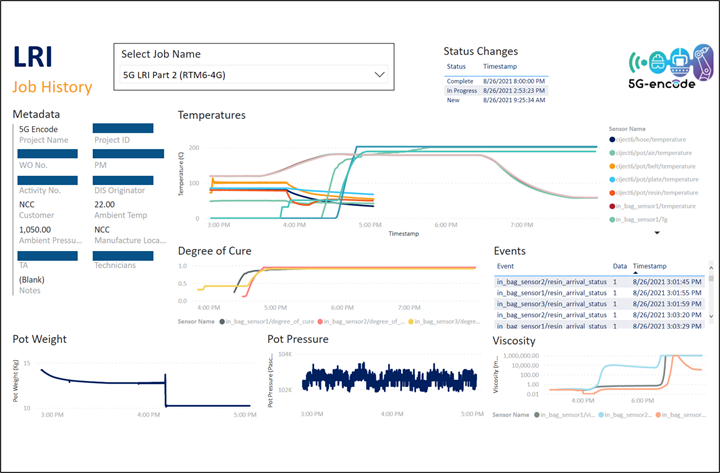

The purpose of the 5G-ENCODE project was to develop a system that could automate elements of the LRI process by using closed-loop manufacturing. The requirements for such systems are threefold: Monitor the key variables, use this data to decide how the process should be altered and then implement the decisions. To meet these core requirements, the project team developed three sub-systems: Sensor Array, Control Model and Feedback System. Additionally, a dashboard visualization system was developed for advanced real-time process monitoring.

The Sensor Array was developed using Synthesites’ innovative in-bag and in-line sensors. In-bag sensors are capable of direct contact with carbon fiber preforms without glass fiber or other insulation, while in-line sensors are used to track the resin when exiting the vacuum bag. The in-bag sensors — in conjunction with Synthesites Online Resin State (ORS) software — provide real-time reliable estimations of resin viscosity, Tg and degree of cure from the sensors’ resistance and temperature measurements.

Automatically-generated part traceability report showing a single view of information from across the LRI process: resin monitoring, injection machine, oven temperature, and part metadata. Photo Credit: NCC, Synthesites, 5G-Encode project case study

Synthesites also developed an intelligent valve control system that can open and close resin valves without human interaction. These were placed on the resin outlets in the 5G-Encode demonstrator.

The NCC created a 5G-enabled Internet of Things (IoT) platform and developed software to integrate both the sensors and valve control system into this IoT platform. A resin injection machine was also upgraded so that it can stream its data to the IoT platform in real time. All data and control decisions were sent over 5G.

The NCC also developed a control model that used the live process data from the sensors and made decisions on the process. It then sent commands to the valve control system — thus, achieving closed-loop control. All sensor data was visualized in real time on cloud-based dashboards.

For further details, see multiple publications on the 5G Encode website: https://www.5g-encode.com/media-and-publications

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.