UK's Composites Engineering Show features latest in composites technology

Composites technologies for automotive, mass transit and aerospace abounded at the Composites Engineering Show in Birmingham, UK, Nov. 11-12.

The annual Advanced Engineering UK show was once again held at the Birmingham, UK, National Exhibition Centre (NEC), Nov. 11-12. The show is a group of events that fills the spacious Hall 5 of the NEC and comprises five events held concurrently under one roof. As well as the Composites Engineering Show there were shows devoted to aero engineering, automotive engineering, auto electronics and performance metals engineering.

The Engineering Show began in 2009 with the Aero Engineering show and was joined by the Composites Engineering Show in 2010. In that year there was a total of 180 exhibitors, of which 80 were composites and attracted 3,500 visitors. Since then the show has grown year-on-year with more than 250 composites exhibitors and visitors, topping 13,000 this year. The Composites Engineering Show at the NEC is now the UK's largest event of its kind. This year there were many free-to-attend open conference sessions; of the 200-plus presentations, 43 were devoted to composites.

Those attending the show to see glamorous new products made from composites were not to be disappointed. For example, the McLaren 650S (see photo), unveiled earlier this year at the Geneva Motor Show, was proudly on display with its carbon fiber composite monocoque weighing in at 75 kg.

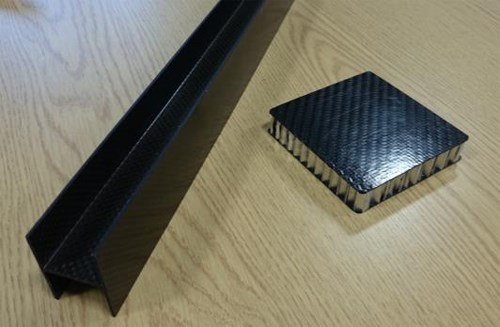

At perhaps a more affordable level, but still aimed at low-volume niche automobile producers, Far Composites (Nottingham, UK) displayed its very recently launched Far Platform Chassis (FPC). Far had already worked with vehicle makers on a number of composite chassis and frames but the cost of putting each structure through the full panoply of regulatory testing was very high. To substantially reduce this cost, Far developed the FPC, which is a standardiszed unit that vehicle builders can purchase off-the-shelf and use as the basis of their own constructions. The whole chassis and frame construction weighs in at just 50 kg. The chassis meets and exceeds the highest safety requirements in line with the company's Light and Safe (LiSa) design philosophy. As well as crash safety, it has also been designed for easy repair (see photo)

The National Composites Centre, (NCC, Bristol, UK) had its stand at the heart of the exhibition. The Phase 2 building of the NCC, which effectively doubles its size, was officially opened on Oct. 30 and represents a further major investment by the UK government in the composites industry. As well as a display of the NCC's recent acquisition of a Schuler HP-RTM press (picture), which is the largest open access equipment of its type worldwide, a notable exhibit was a fully tested underground train door. The door on display (picture), manufactured by a dedicated team at the NCC from thermoplastic composite based on polyetherimide (PEI) polymer matrix, has completed the very demanding regime of strength and fire safety testing required by the UK's London Underground.

For London Underground the application of these lightweight, innovative new thermoplastic composite doors on the London's Central Line alone — saving 1.25 tonnes across a train— would mean savings of more than £5 million (USD$7.8 million) a year. The project has already won a UK Rail Industry Innovation Award in the Environment category and has been short-listed for the prestigious Stephenson Innovation Award, which will be announced later this year.

Many of the big-name composites textile producers were present at the show with an impressive range of high-quality fabrics. Notably unique and new though was Chomarat's (Le Cheylard, France; Anderson, SC, USA) range of very thin ply (down to 50 gsm) multi-axial fabrics called C-PLY. The interesting feature of C-PLY is that it allows composite designers to depart from the traditional 0°/90°/45° layup as C-PLY can be supplied in any variant of ply angle to suit a particular design, allowing stronger and stiffer designs that are lighter in weight and more damage tolerant. Notably, as was reported recently by CompositesWorld, C-PLY will be used to fabricate Jean-Marie Finot’s latest yacht, the Albatros. Both the hull and the deck of the boat will be made from C-PLY. There is also significant interest in the material in the aerospace sector.

To get to the real gems of the show, the visitor needed to dig below the surface and look to the many free presentations. For example, surface preparation, adhesive bonding and NDI of composites, both during manufacture and then for in-service repairs, featured in several presentations. If the mass-produced composite automobile is to be an affordable reality for the future, robust repair schemes involving adhesive bonding will be essential, as will high-quality bonds in original manufacture. As another example, in aerospace, aircraft rely on nuts and bolts in assembly as joints solely adhesively bonded cannot be certified because current state-of-the-art NDI technology cannot ultimately prove the effectiveness of the bond. It has been rumored that the largest commercial airliner, the Airbus A380 contains as many nuts and bolts as the Eiffel tower. This may be an exaggeration, but the ability to rely on adhesive bonding would result in huge weight and consequent energy and cost savings. Essentially, where a joint is glued, it also has to be screwed. Some of the new technologies suggested in presentations point the way to how this may be overcome for the future.

Donald Inglis of Agilent Technologies (Santa Clara, CA, US) gave a very interesting paper on a portable Fourier Transform Infrared (FTIR) spectrophotometer (picture), the Exoscan 4100. Effectively, Agilent has brought this powerful technology out of the laboratory and incorporated it into a “point-and-shoot pistol” that can be used as an inspection tool in the production environment to precisely characterise a composites surface. Not only will it ensure that a surface is clean, it will also quantify the precise state-of-cure of the part and measure ionic species that may have been applied to the cured parts surface to enhance bond by plasma treatment.

Richard Freemantle, director of Wavelength NDiT Ltd. (Elton, Derbyshire, UK), also gave an interesting view of future possibilities in ND in his interesting presentation, titled, “Practical NDT techniques for multi-sector composites inspection in a manufacturing an in-service environment”

Complementing bonding, professor Andrew Mills of the UK’s Cranfield University, gave an interesting talk on “Advancements in joining technologies,” demonstrating that by careful design, metallic inserts can be made to maximize bond strength and provide reliable attachment and bonding to composites during part manufacture.

So, for the future perhaps we may be able to put more confidence in gluing without having to resort to so much screwing.

The normally ubiquitous subject of out-of-autoclave (OOA) was not obviously visible at the show. There were numerous displays of very attractive composites parts on show, but had nothing to say on the manufacturing technology used to make them. OOA was strongly alluded to though in the very interesting presentation given by professor Simon Hayes of the University of Sheffield, UK, on “Direct electrical cure of carbon fibre composites.” Hayes and his team have been able to demonstrate that by taking advantage of the electrically conductive nature of carbon fibere in composites, it is possible to effect at least as good a state of cure by direct resistive heating as with very inefficient conventional convective means of cure, such as autoclave, at a fraction of the time and energy. The cure of a 1m-long beam, for example, was effected using just 160W of energy (see picture)

Another approach to reduce the cost of composites manufacture was described by professor Kevin Potter in his presentation, “Design for manufacture: Advancing lamination technologies.” The work began with “electronically observing” the layup methods of highly skilled human laminators and inputting this data into a computer model. These data are used as a training aid and, ultimately, could lead to complex laminated parts made by robots with minimal human intervention.

Related Content

The Native Lab launches composites course training membership plan

Courses that touch on the fundamentals of composite materials, design, analysis and more are available for individuals and companies alike through TNL’s online platform.

Read MoreFACC Academy begins training, onboarding operations

FACC’s newly launched training platform will address skilled aerospace worker shortages head on, offering more than 250 specialized training courses for its entire workforce.

Read MoreNASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

Read MoreZeiss, Imperial College London summer school enhances materials, sustainability learning

Twenty-four next-generation students attended the Imperial College London this August to advance their scientific knowledge, with workshops, lectures, activities and a composites competition.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)