NASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

Share

NASA (Washington, D.C., U.S.) has selected four teams of university faculty and students to solve key challenges facing the future of air travel as part of the agency’s University Leadership Initiative (ULI). This initiative gives the academic community an opportunity to support NASA’s aeronautical research goals and provide students experience in cracking real-world technical challenges (learn more about ULI here).

“The University Leadership Initiative is an integral part of our research portfolio,” Bob Pearce, associate administrator for the Aeronautics Research Mission Directorate at NASA headquarters in Washington, notes. “The multidisciplinary teams are directly contributing to our priorities and even leading the exploration of solutions beyond our current portfolio.”

Three of the four teams will address topics related to ensuring the safe growth of advanced air mobility (AAM), while the fourth will examine an option for generating electricity to propel a future airliner. As the teams work on their projects, they will collaborate with other universities and industry partners, creating opportunities for participation that include students with diverse experiences, backgrounds and talents.

“This multidisciplinary approach enables the lead teams to partner with others, including student populations who are underrepresented or have not been involved before in aviation research,” Koushik Datta, University Leadership Initiative project manager, adds. “As we look to future growth in AAM and an increasing emphasis on creating truly sustainable aviation, it’s important we involve today’s students in helping us solve tomorrow’s challenges.”

The four teams selected for final negotiations could lead to awards worth a combined total of up to $25.1 million during the next four years. The teams and their research topics are:

New Mexico State University

The team will gather data about current and projected AAM operations to help produce models that could inform decisions on how the electric grid infrastructure can support future AAM activity, including the demand for aircraft charging stations.

Team members include:

- The George Washington University

- University of Tennessee in Knoxville

- University of Tennessee in Chattanooga

- University of Maryland in Baltimore County

- Aurora Flight Sciences Corp. (Manassas, Va., U.S.)

- Argonne National Laboratory (Lemont, Ill., U.S.)

- Whisper Aero (Crossville, Tenn., U.S.)

Boston University

The team will focus on developing models for predicting how to minimize noise from AAM vehicles flying within dense urban environments where wind conditions can rapidly change. These models also might provide guidance on suitable locations for vertiports that minimize noise during takeoff and landing.

Team members include:

- Embry-Riddle Aeronautical University

- Tuskegee University

- Virginia Polytechnic Institute and State University

- Joby Aviation (Santa Cruz, Calif., U.S.)

University of Notre Dame

The team intends to develop an automated decision-making capability that ensures small drones are safe before they fly using a NASA-developed drone traffic management system. This automated system would replace a manually intensive process that is limited in its ability to handle increasing drone traffic.

Team members include:

- Iowa State University

- Saint Louis University

- University of Texas in El Paso

- DePaul University

- DroneResponders Public Safety Alliance (Miami Beach, Fla., U.S.)

Tennessee Technological University

The team aims to develop a preliminary design for an electrified 150-passenger aircraft that uses an ammonia-based integrated propulsion, power and thermal management system.

Team members include:

- Tennessee State University

- The Ohio State University

- University of Dayton

- University of Washington – Bothell, Boeing Research & Technology

- Raytheon Technologies Research Center (East Hartford, Conn., U.S.)

- Special Power Sources (Alliance, Ohio, U.S.)

This is the sixth round of awards for the initiative. Selections of four teams and six teams were made in 2021. Five teams were chosen in 2020, three teams were announced in 2019 and five teams were selected for the inaugural initiative in 2017.

An official notice for the next request for proposals is expected later this year.

Related Content

Zeiss, Imperial College London summer school enhances materials, sustainability learning

Twenty-four next-generation students attended the Imperial College London this August to advance their scientific knowledge, with workshops, lectures, activities and a composites competition.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreChemnitz University of Technology receives €6 million to expand research into "green" carbon fiber

Carbon LabFactory and InnoCarbEnergy project conduct R&D across entire value chain from raw materials through processes to structures and systems on a pilot line with technology demonstrators.

Read MoreBelzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreRead Next

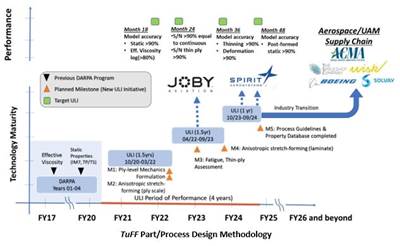

UD’s Center for Composite Materials hosts NASA University Leadership Initiative

October meeting of industry, government and academic accentuates the University of Delaware’s study of research and technology barriers in UAM using its new class of composite materials, TuFF.

Read MoreCollaborators awarded NIST funding to develop in-space manufacturing roadmap

Purdue, the University of New Hampshire and the University of Alabama will work with NASA to develop a roadmap for in-space manufacturing.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More