University of Nottingham commissions resin metering system for short fiber compression molding

Slack & Parr’s precision external gear pumps enable the university’s EPSRC Future Composites Manufacturing Research Hub to precisely determine the fiber-to-resin ratio for their robot-mounted liquid resin spray system.

Slack & Parr's gear pumps are machined to extremely precise tolerances to deliver accuracy and control even at high pressure. Photo Credit: University of Nottingham, Slack & Parr

Precision metering pump specialist Slack & Parr (Derby, U.K.) has been commissioned by the University of Nottingham (U.K.) to supply its high-precision metering technologies as part of a short fiber compression molding system to manufacture composite parts for the automotive industry.

The short fiber compression molding approach has been developed by a team from the EPSRC Future Composites Manufacturing Research Hub at the University of Nottingham, led by Professor Nick Warrior and Dr. Anthony Evans. Their objective has been to develop an out-of-autoclave (OOA) manufacturing technology that accommodates lower cost, short fiber formats as a way of making composites more viable and cost-efficient and supporting the transport industry’s ambitions to become more fuel-efficient and sustainable. The solution is being used to manufacture components including complex-shaped under bonnet and suspension parts for automotive.

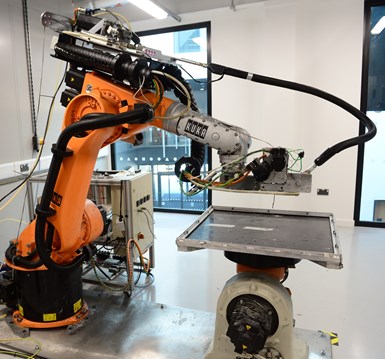

The university’s technology uses a liquid resin spray (LRS) system to apply the resin matrix to short form (25-millimeter) carbon fibers activated by an air stream. In this way, the resin and the fibers are said to make complete and uniform contact with each other without the need for mechanical application.

Professor Nick Warrior explains how Slack & Parr’s precision external gear pumps are key to the resin metering and spraying stages of the process: “Slack & Parr’s metering pumps allow us to control precise amounts of the resin’s constituent parts to achieve a matrix with the exact characteristics we need,” Warrior says. “Being able to accurately meter each ingredient means we can mix the resin matrix to a viscosity that can be sprayed reliably and effectively without having to rely on the overuse of solvents. Varying the percentages even slightly at this stage can result in a resin that may not spray or cure correctly, so accuracy is crucial here. We can also adjust the metering pump to create new resin systems with different characteristics, for example faster curing and better mould release to help us achieve our target 30-second cure cycle.”

The University of Nottingham has developed a robot-mounted liquid resin spray system incorporating Slack & Parr's precision metering technology. Photo Credit: University of Nottingham, Slack & Parr

Slack & Parr’s metering pumps are built around hardened steel involute gears which are machined to precise tolerances of one or two microns. The company says this results in extremely small, controlled clearances — measuring less than a human hair — between the gear and mating components, ensuring almost no internal slip even at high pressures. This level of precision means the pump is able to control or meter the flow with extreme accuracy and repeatability.

In the university’s system, each part of the resin matrix is held separately to prevent curing and mixed only at the point of application. The metered matrix is then sprayed directly from the resin mixing tank onto the short form carbon fiber filaments which are simultaneously propelled into a controlled air stream via a robot head. The resin-coated carbon fibers are subsequently molded to form a composite component.

The University of Nottingham’s application requires three different fluids with different viscosities to be brought together at the same rate and in the right ratios to achieve the desired resin matrix and to ensure consistency and repeatability of the process. Using Slack & Parr’s gear pump technology, the university team was able to achieve a consistent flow throughout the process despite varying pressures linked to the different viscosities of the fluids.

“Our pump solutions are relevant to every area of the composites industry where the need to precisely determine the fiber-to-resin ratio is key to the manufacture of consistent composite materials and parts,” Neil Anderton, hydraulics and industrial director at Slack & Parr points out. “Importantly, the technology can also be extended out to other polymer resins and plastics to offer the same level of performance.”

Related Content

Belzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreComposites UK launches best practice guide for composites tooling

“Mould Tooling for Fibre-Reinforced Polymer Composites” is latest in Composites UK’s series of good practice guides, available online for free.

Read MoreZeiss, Imperial College London summer school enhances materials, sustainability learning

Twenty-four next-generation students attended the Imperial College London this August to advance their scientific knowledge, with workshops, lectures, activities and a composites competition.

Read MoreNASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)