U.S. Air Force funds effort to improve composite rotor blade design analysis capabilities for AAM

AnalySwift partners with Weber State, BYU, UAMMI and Hexcel for materials research, qualification and to extend VABS’ capabilities to AAM blades for a user-friendly and highly rigorous simulation framework.

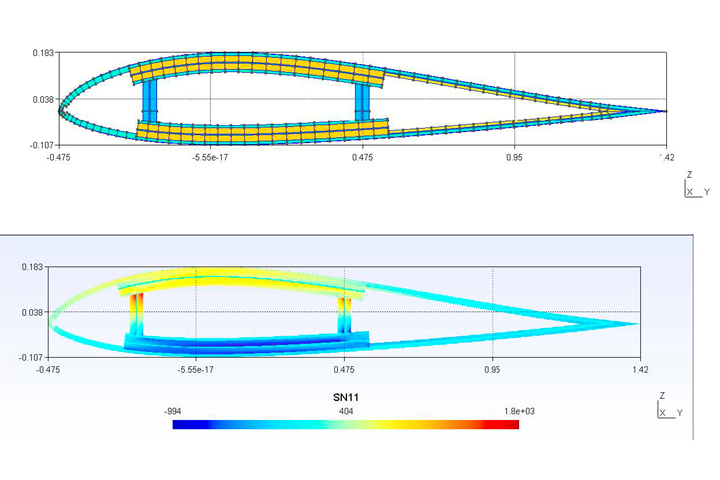

Air foil meshed cross section viewed in Gmsh and Contour plot of recovered nodal stress SN11. Photo Credit: AnalySwift LLC

While great strides continue to be made in advanced air mobility (AAV), there are still several challenges ahead, particularly in the complexity of designing and modeling composite rotor blades. To address this challenge, AnalySwift LLC (West Jordan, Utah, U.S.), a Purdue University-affiliated software company that provides efficient high-fidelity modeling software for composites, is partnering with Utah-based Weber State University, Brigham Young University (BYU), Utah Advanced Materials and Manufacturing Initiative (UAMMI, Kaysville, U.S.) and Hexcel (Stamford, Conn., U.S.). The contract is funded through the U.S. Air Force’s (USAF) Small Business Technology Transfer (STTR) program.

Specifically, the contract with USAF’s AFWERX program — a program that seeks to accelerate the development of a commercial market for advanced air mobility (AAM) — is to develop a framework for the design of composite rotor blades used in AAM vehicles. AnalySwift notes that, while offering weight and performance advantages, such blades can be made of dozens of separate layers of composite materials, creating challenges when conducting design and analysis. For instance, representing these blades in a computer model could require billions of degrees of freedom to accurately capture all the engineering properties.

To accomplish this, several key research tasks are being carried out, including development of the framework at AnalySwift to extend VABS’ capabilities — a general-purpose, cross-sectional analysis tool for composite blade simulation — to AAM blades, materials research and qualification at Weber State, manufacturing simulation at BYU and industry collaboration with UAMMI. Corporate partner, Hexcel, is providing innovative composite materials, which AnalySwift believes may one day be the standard for AAM rotor blades.

The overarching goal of this project is to enable rapid development and certification of AAM vehicles through a digital engineering framework for this critical component, namely the rotor blade. It will not only extend the capabilities of VABS from helicopter rotor blades to AAM blades, says AnalySwift, but it also links several other programs and capabilities with VABS as well in a user-friendly framework.

Weber State itself is becoming an epicenter for the applied study of composites. The university’s new post-graduate Systems Engineering and Sustainable Engineering Certificate, as well as two new state-of-the-art engineering buildings support their advanced teaching and research. Weber State professor of mechanical engineering Daniel Magda will lead technical efforts to qualify materials provided by Hexcel for properties important in the performance of composite blades, such as stiffness and strength. This testing according to ASTM standards is important for qualifying the materials as inputs for the blade modeling framework.

BYU is a private research institution with a newly created department of Manufacturing Engineering focusing on both theory and hands-on learning of common manufacturing processes. BYU has expertise in modeling and simulation of resin infusion composites processing. Under the direction of associate professor Andy George, BYU will perform flow simulation and infusion process optimization for low void content for blade and manufacturing constraints to AnalySwift to incorporate into the design.

Some of the key benefits of the envisioned final product include improved vehicle competitiveness with highly rigorous simulation of composite rotor blades, reduced time to market with orders of magnitude reduction in analysis time, less reliance on costly and time-consuming experiments and a convenient engineering platform for wide usage that doesn’t require finite element analysis (FEA) expertise to operate. These benefits potentially add up to significant time and cost savings for those developing AAM vehicles.

More specifically, AnalySwift says the VABS-enabled framework can help deliver AAM blade engineers the best complete set of beam properties, which are needed for static/dynamic design and analysis of rotor blades as well as the complete set of accurate stresses/strains/strength ratios for assessing

the structural safety of the blades. The VABS program is said to be extensively validated in helicopter and wind industry for accuracy and is highly optimized for ply-level details modeled in seconds.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Simulation software leveraged for rotor blade project

Seoul National University uses Analyswift’s composite simulation software, VABS, for more accurate design and analyses in the university’s experimental evaluation of a SNUF rotor blade.

Read MoreCarleton University leverages VABS software for helicopter blade simulation

As part of AnalySwift LLC’s Academic Partner Program, Carleton University is working on new comprehensive software to simulate helicopter blade tasks.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)