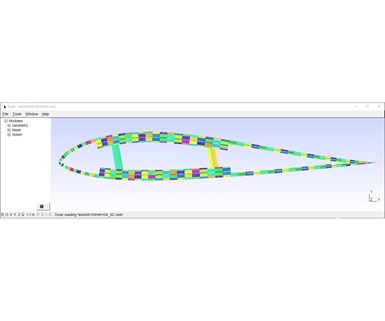

Carleton University leverages VABS software for helicopter blade simulation

As part of AnalySwift LLC’s Academic Partner Program, Carleton University is working on new comprehensive software to simulate helicopter blade tasks.

Source | AnalySwift LLC

AnalySwift LLC (West Jordan, Utah, U.S.), a provider of efficient high-fidelity modeling software for composites, announced on Dec. 3 that Carleton University (Ottawa, Ontario, Canada) is participating in its recently launched Academic Partner Program (APP) and is using its VABS simulation software for simulating new helicopter rotor blades. The work is part of the Rotorcraft Laboratory at Carleton University, a research group working on new comprehensive software for helicopters in order to study various tasks such as aerodynamics, structural dynamics, flight mechanics and control.

Supervised by Dr. Fred Nitzsche, professor in the Mechanical and Aerospace Department, over the past 20 years, the Rotorcraft Laboratory collaborates with several European universities to accomplish these tasks.

“We are excited by the work being done by Carleton University and are pleased they have selected VABS as part of their composite helicopter rotor blade simulation workflow,” says Allan Wood, president & CEO of AnalySwift.

The Academic Partner Program (APP) is designed to offer participating universities no-cost licenses of its engineering software programs VABS and SwiftComp so that students, researchers and faculty can leverage the tools in their academic research. AnalySwift says the program also affords students an additional avenue to highlight their research, as AnalySwift periodically spotlights papers, theses and articles involving the codes. The company has also established a robust community of users who can help answer questions through the online cdmHUB (composite design & manufacturing HUB) platform.

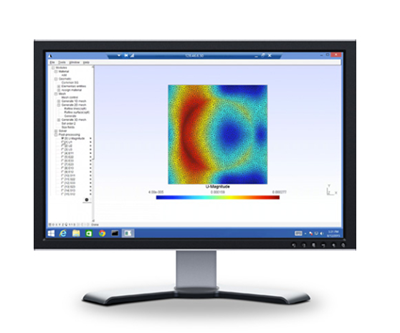

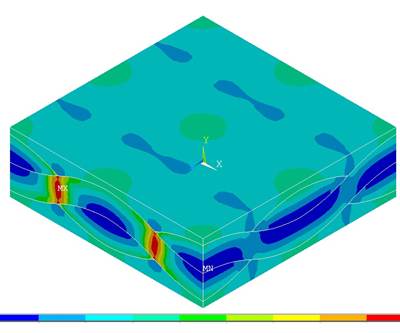

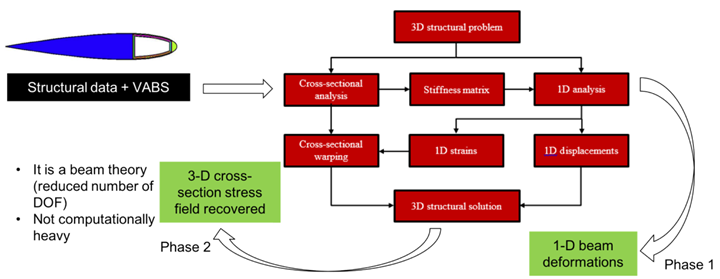

According to the company, the VABS program is a general-purpose cross-sectional analysis tool for computing beam properties and recovering 3D stresses and strains of slender composite structures. It is a tool for rigorously modeling composite helicopter and wind turbine rotor blades, as well as other slender structures such as propellers, landing gear and high-aspect ratio wings.

Flowchart showing the relation between VABS and the current task. Source | Carleton University

“Many helicopter and wind turbine blades are made of composite materials and have relatively complex geometry,” says Dr. Ali Siami, postdoctoral fellow in the Mechanical and Aerospace Department of Carleton University. “In order to model them correctly, the structural properties of these blades should be extracted thoroughly. VABS, which calculates the structural properties of blades, will be used in this project to accomplish this. The results of this project will be used to design rotorcraft with more realistic models that are provided in the new developed software. The results can also be extended to wind turbines.”

“The VABS program is a uniquely powerful tool for modeling composite blades, high aspect ratio wings, and other slender structures, commonly called beams,” says Dr. Wenbin Yu, chief technical officer of AnalySwift. “VABS reduces analysis time from hours to seconds by quickly and easily achieving the accuracy of detailed 3D finite element analysis (FEA) with the efficiency of simple engineering models. With VABS, engineers can calculate the most accurate, complete set of sectional properties such as torsional stiffness, shear stiffness, shear center for composite beams made with arbitrary cross-section and arbitrary material. It can also predict accurate detailed stress distribution for composite beams, which are usually not possible with 3D finite element analysis (FEA) for realistic composite structures.”

Related Content

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreRead Next

SGL Carbon delivers composite materials for Airbus Helicopter rotor blades

SGL Carbon’s glass fiber noncrimp fabrics enable the composite rotor blades for the 5 blade Airbus H145 rotor configuration.

Read MoreAnalySwift launches academic partner program for composites simulation software

Through its Academic Partner Program, AnalySwift now offers universities no-cost licenses for its SwiftComp and VABS tools for academic research.

Read MoreBeijing Institute of Technology leverages SwiftComp for composites research

The university is using AnalySwift’s simulation software as part of the company’s Academic Partner Program.

Read More

.jpg;width=70;height=70;mode=crop)