Airtech launches high temperature vacuum bagging materials for thermoplastic molding

The company has released a new high performance release film, a new sealant tape for high temperature applications and non-woven blended, fiberglass breathers.

Airtech Advanced Materials Group (Huntington Beach, CA, US) in September introduced new high temperature vacuum bagging materials for thermoplastic molding processes up to 426ºC. The products include:

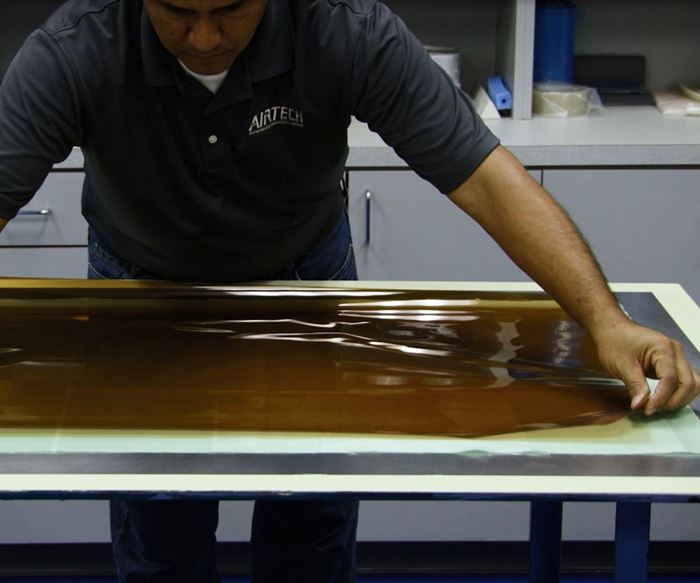

Thermalimide RCBS, a high performance release film treated on both sides for cure temperatures up to 761°F (405°C). The film is designed for use during the forming process of thermoplastic materials and other high temperature applications. According to Airtech it can be used safely at high temperatures, offers good release off cured parts and has flexibility for applying pressure over simple contoured shapes.

Fast Tack HT, a new generation sealant tape for high temperature applications. The tape reportedly builds tack quickly when applied to Thermalimide and adheres well to polyimide films. It is said to have good room temperature adhesion to the high temp bagging film, reportedly reducing the time required to vacuum bag high temperature parts.

Airweave UHT 300PGL and Airweave UHT 450PGL, premium non-woven blended, fiberglass breather for ultra high temperature applications. According to Airtech, it is safer to use these breathers in place of woven fiberglass breathers. The breathers reportedly make an easier transition for the vacuum bag and in any radius. One layer provides good breathing to 800°F (427°C). The products are designed for use with high temperature thermoset and thermoplastic resin systems.

Related Content

-

Braskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

.jpg;maxWidth=300;quality=90)