ARIS introduces polymer-free ceramic composite

Fireproof, lightweight ceramic material ALEC2 is highly sustainable, suitable for manufacturing a variety of aerospace products, as well as marine and other industries.

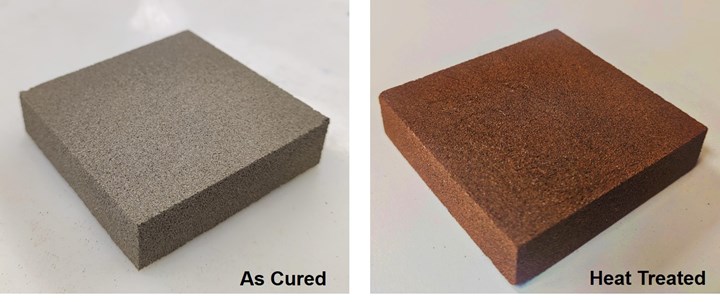

Applied Research and Industrial Services Inc. (ARIS, Greensboro, N.C., U.S.), in collaboration with business development company WT&C (Alberta, Canada), announces the development of ALEC2, a patent-pending ceramic material that is 100% sustainable, fireproof, lightweight and polymer-free. It is suitable for manufacturing a variety of aerospace products such as sandwich panel and cargo liner components, and is flexible for use in marine and other end markets.

ALEC2 is comprised of ~85% eco-friendly industrial mineral waste, is completely recyclable and reduces the carbon footprint associated with aerospace composites manufacturing, according to ARIS. With safety paramount to this industry, the ceramic material is engineered to be fireproof, not just fire-resistant, with low thermal conductivity, contributing to increasing crew and passenger safety while significantly reducing the impact and risks of in-flight fire events. This characteristic is further aided by the materials entirely polymer-free nature, eliminating the release of toxic fumes in the event of fire.

ALEC2 is said to be lightweight, even more so in comparison to aluminum and polymer-based composites — approximately 1/5 the density of aluminum and 1/3 the density of carbon fiber-reinforced epoxy. It has a softening temperature of ~1,000°C, compression strength of 750-1,000 psi and flexure strength of 450 psi. ALEC2 can be nailed, machined and bonded and molded to very complex shapes.

ARIS anticipates that this new material will have far-reaching implications across the aerospace materials industry.

Contact Bill Hayward for further performance data and commercial opportunities for ALEC2 via email (alec2.com) or phone (403-608-2449).

Related Content

-

HRC, Airbus LSC launch aircraft dismantling, recycling project

The first project is underway to recover carbon fiber used in an A330-200 aircraft, which will then be regenerated for other end uses by HRC.

-

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

-

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.