Brook One introduces burnthrough cover films for aerospace

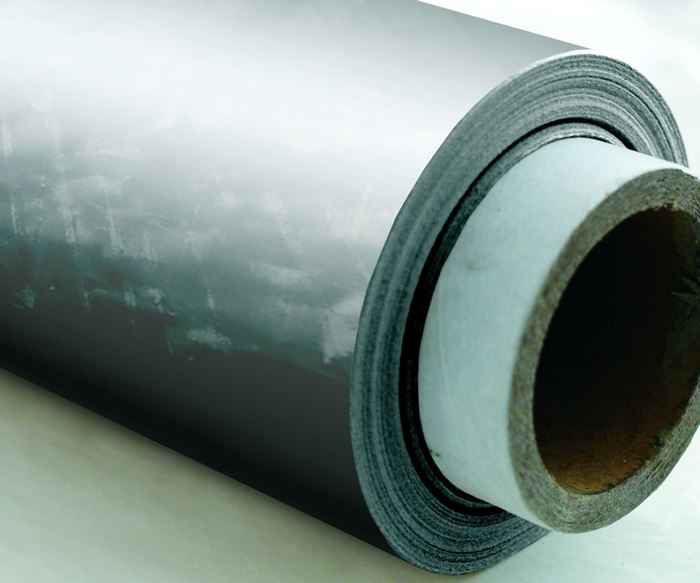

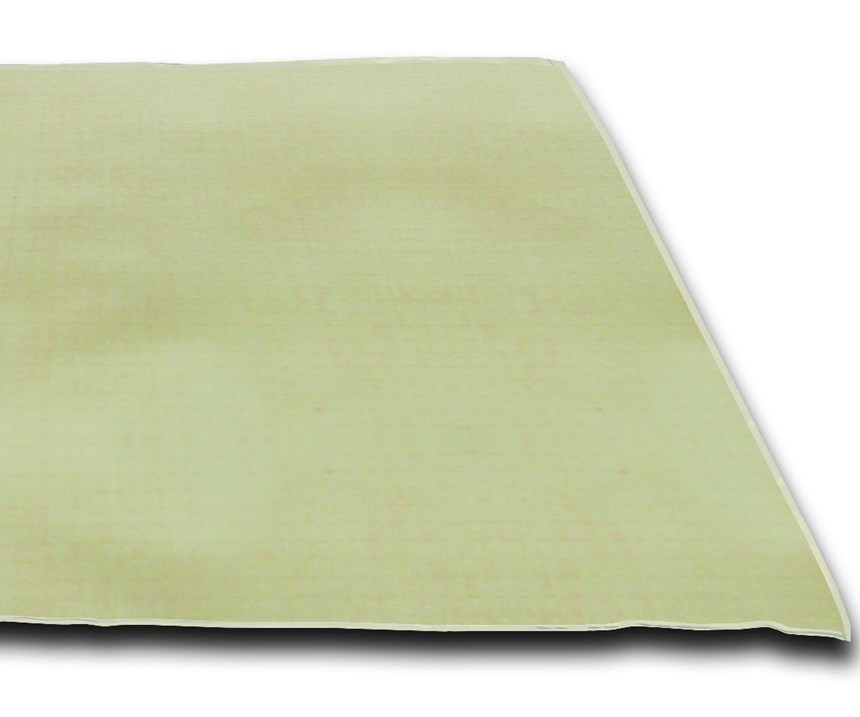

Brook One Corp. has introduced two burnthrough cover films for the aerospace industry, BO 856B-I-LWT (metallic) and BO 856B-II-LWT (non-metallic).

Brook One Corp. (Toronto, ON, Canada) has introduced two burnthrough cover films for the aerospace industry, BO 856B-I-LWT (metallic) and BO 856B-II-LWT (non-metallic). These films are said to be up to 15% lighter than standard competitive products. Features include:

- Woven and nonwoven formats are bendable, reportedly abuse-resistant, are said not delaminate and will not peel

- PEEK-based cover film offers good excellent mechanical/chemical properties in high-temperature conditions

- Reportedly long “no burn-through time” with low heat flux readings

These cover films are specifically designed for aircraft fuselage thermal/acoustic insulation systems, and are said to be formulated to meet Aircraft Fuselage Burnthrough Regulations.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.