CAD viewer software updates simplify printing, two-way file flow

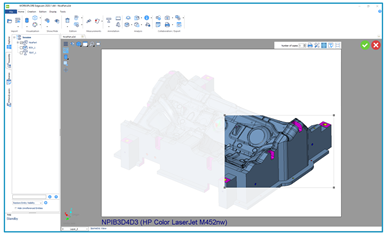

The 2020.1 software release for Hexagon’s WORKXPLORE includes enhancements for specific simulation import, additional reader translators and client viewer measurements.

Source | Hexagon Manufacturing Intelligence

WORKXPLORE is a high-speed CAD viewer and analyzer from Hexagon Manufacturing Intelligence’s (North Kingstown, R.I., U.S.) Production Software portfolio. The 2020.1 software release includes enhancements for specific simulation import, additional reader translators and client viewer measurements.

The software was originally created to efficiently import and analyze all file types and sizes at high speed. According to Hexagon, using WORKXPLORE often enables users to take less than half the time to open a file compared to the original CAD application.

Among the new and enhanced two-way workflow functionality in WORKXPLORE 2020.1 is the ability to import and export the IGP file format for the Hexagon I++ Simulator, which is a server-based software for multi-kinematic simulation of process-oriented inspections to automate production metrology.

WORKXPLORE can export either opened or closed solids, mesh models as meshes, and also import meshes.

Source | Hexagon Manufacturing Intelligence

Additional reader translators include Solid Edge 2D Importer and the IGES Reader Translator. The ability to read drawings has been added to the Solid Edge interface. Currently, 2D supported versions are ST1 to 2019. The IGES translator allows users to choose between the in-house integrated import library and the Datakit Advanced Import, giving a choice for the setting best suited to specific needs.

A Print Option enhancement gives more interactive printing functionality in the single view layout by manipulating entities over the printing. According to the company, the printing zone in this enhancement can be defined through an interactive rectangle, with the ability to move the camera in the 3D screen. When the command is launched, a mask corresponding to the paper ratio appears onscreen and enables users to move the model to precisely define the printing area. Another interactive rectangle provides an optional crop facility. A toolbar with the print options is also now available on the right side of the screen, making it easier to select the target printer and define its properties, select the paper size and add headers and footers.

Another new function enables measurements done in WORKXPLORE to be exported to the Client Viewer.

Translators in WORKXPLORE 2020.1 support a number of main formats, including ACIS, several CATIA products, Creo, DXF/DWG, IGES, EDGECAM, I++ Simulator, INVENTOR, Parasolid, STEP, Solid Edge and SolidWorks.

Related Content

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)