CAMX 2019 exhibit preview: Goodwinds Composites

Goodwinds Composites will showcase its micro-pultruded carbon rods, wrapped carbon tubes, and composites machining capabilities at CAMX 2019.

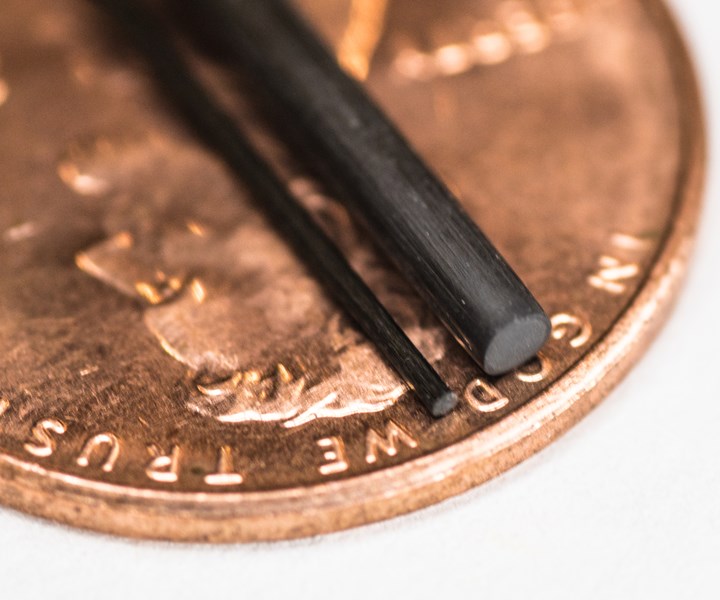

Micro-pultruded carbon rods

Source | Goodwinds Composites

Goodwinds Composites (Mount Vernon, Wash., U.S.) will showcase its micro-pultruded carbon rods, wrapped carbon tubes, and composites machining capabilities at CAMX 2019 (Booth Z46), September 23-26, in Anaheim, Calif.

The micro-pultruded carbon rods are produced in short runs and can have a diameter as small as .020 inches. Frequently used for z-axis reinforcement of laminate stacks, Goodwinds Composites’ micro carbon has all the attributes of larger pultruded carbon rods such as excellent stiffness-to-weight ratio and high Fiber volume Fraction. Additionally, tooling costs for custom micro-pultruded rods are relatively low.

Goodwinds Composites’ wrapped carbon tubes can be found in guitars, tents, backpacks, hiking poles, pool cues and the NASA Mars Helicopter. Goodwinds Composites is well-versed in metrology and can precisely and repeatedly machine composite rods and tubes to tight tolerances. The company’s capabilities include notching, milling, drilling, sanding, cutting and grinding to specific outer diameters.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

.jpg;maxWidth=300;quality=90)