CAMX 2022 exhibit preview: Parabeam

Parabeam’s 3D E-glass woven fabrics, particularly ParaGlass and ParaTank, continue to advance composite sandwich structures with high flexibility, strength and application versatility.

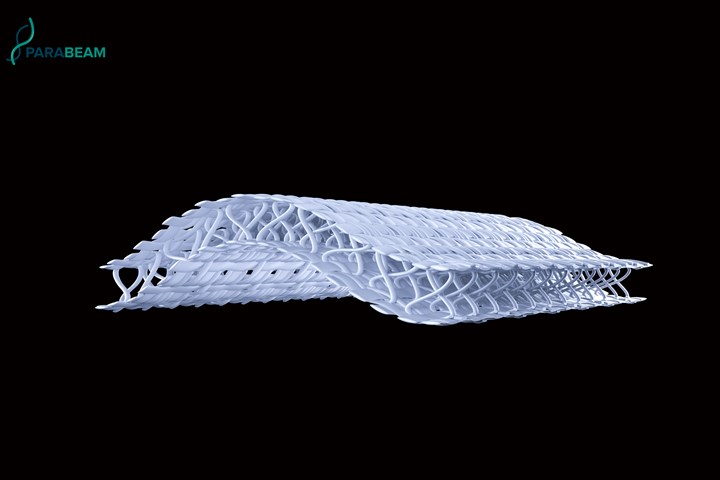

Parabeam (Helmond, Netherlands) is the inventor and original manufacturer of 3D fiberglass woven fabric for sandwich construction. Inspired by traditional weaving methods, the company’s product is made of 100% E‑glass yarn; two bi-directionally woven deck layers are bonded together by vertically braided eight‑shaped pillars. Parabeam says the pillars act like springs and push the deck layers apart to a predefined height. This creates a flexible, fire- and corrosion-resistant, and versatile yarn that has found global application in the petrochemical, aerospace, public transport, marine and construction industries. The company keeps a stock of its material in the U.S.

Parabeam highlights its two products, ParaGlass and ParaTank. The ParaTank fabric was developed for use in single-wall and double-wall tanks. The hollow created between the deck layers is said to strengthen the tank structure and creates an interstitial space for leak detection. ParaGlass employs a similar feature with the creation of a permanent, hollow space between deck layers. According to Parabeam, when resin is applied, it only saturates the glass yarn, without filling those hollows. Hand layup, vacuum infusion, closed molding and inline product are all process options for this material. Thicknesses are available from 0.12" up to ½" and widths of 25" or 50".

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;maxWidth=300;quality=90)