CAMX 2022 exhibit preview: University of Dayton Research Institute

The University of Dayton Research Institute supports composite manufacturers from the beginning of the design process through first-article fabrication and subsequent testing.

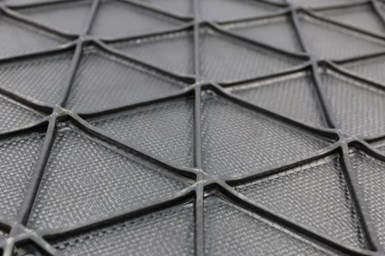

Photo Credit: University of Dayton Research Institute (UDRI)

The University of Dayton Research Institute (UDRI, Dayton, Ohio) says it has been on the cutting edge of composites advancements for more than 60 years, supporting composites manufacturers from the beginning of the design process through first-article fabrication and subsequent testing.

UDRI owns and operates the Dayton Composite Center, which serves as a demonstration work ell for new composite innovations as well as current best practices. In addition, UDRI has fully equipped labs for mechanical testing (coupon through full structures), non-destructive analysis, additive and subtractive machining and aerospace sustainment. UDRI says its team of more than 700 professionals is available to provide their expertise and experience to any composite-related need.

Related Content

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

-

Inha University incorporates SwiftComp simulation software to virtually test composites

AnalySwift’s SwiftComp tool aims to mitigate the burden of costly experiments and enable accurate testing of woven and braided composite structures.

-

Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

.jpg;maxWidth=300;quality=90)