Hexcel low-temp-cure adhesive targets marine applications

Hexcel has launched its new low-temperature, fast-cure HexBond 679 adhesive film.

Hexcel (Stamford, Conn., U.S.) has launched its new low-temperature, fast-cure HexBond 679 adhesive film. HexBond 679, says Hexcel, delivers strong bonding performance in sandwich structures and offers significant cycle time reductions with its short-cure cycles at low temperatures. Formulated specifically to meet the low-temperature cure requirements of marine and industrial applications, HexBond 679 is a 250-gsm supported epoxy adhesive film that is fully compatible with the HexPly M79 prepreg range. Curing in four hours at 80˚C/176˚F or eight hours at 70˚C/158˚F, HexBond 679 films are said to provide extremely high lap shear and peel strength performance, as well as shelf-life of up to six weeks at 23˚C.

Hexcel says HexPly M79 prepregs and HexBond 679 adhesive films allow boatbuilders to increase build rates with reduced heating and cooling times. When combined with Hexcel’s air venting Grid Technology HexPly M79, UD carbon tapes can be laminated with reduced debulking steps to produce porosity of <1%, regardless of laminate thickness.

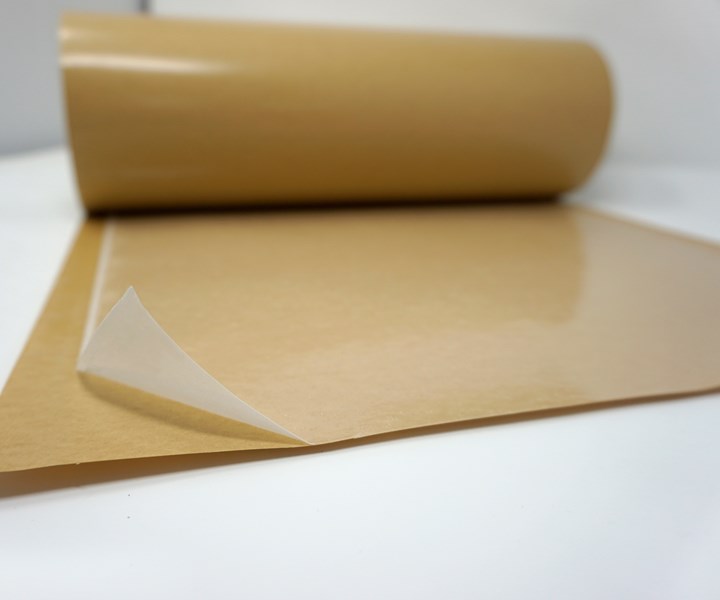

Hexcel HexBond 679 film adhesive. Source | Hexcel

HexBond 679 adhesive film has also received DNV-GL Type approval as part of Hexcel’s latest accreditation program, providing vessel manufacturers with additional independent assurance of the product’s quality, performance, and consistency.

Related Content

-

Alliance for European Flax-Linen and Hemp reports increasing flax fiber adoption in marine

The natural fiber is increasing traction across several marine applications, including in projects by Greenboats, Northern Light Composites, the Beneteau Group and others.

-

Chantiers de l’Atlantique reveals 66-meter, all-composite SolidSail mast

A technological feat, the large carbon fiber mast prototype targets the Silenseas sailing liner and sailing cargo ships for up to 40% reduction in CO2 emissions.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.