In-mold coating offers high-performance finishing for epoxy-infused composites

ODG Composites’ Element Xtreme is a lightweight, long-lasting protective and aesthetic coating suitable for a range of industrial and commercial applications.

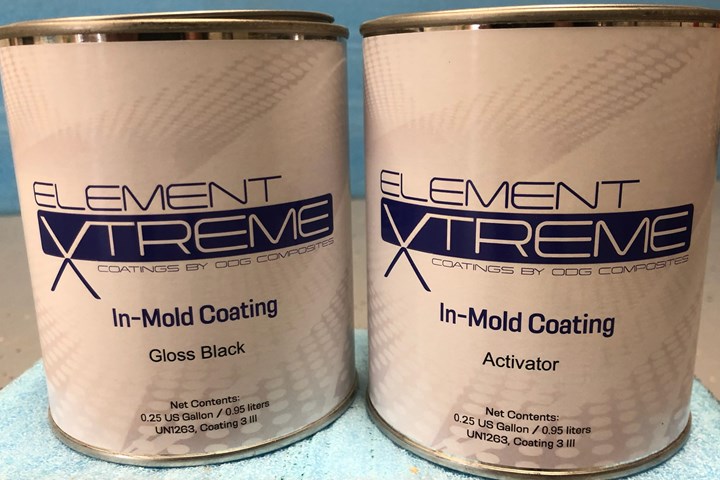

ODG Composites LLC (Saginaw, Texas, U.S.) has launched Element Xtreme Coatings, a specialty in-mold coating designed for exterior durability, flexibility and adhesion when applied to infused, epoxy-based composite parts.

According to Russ Emanis, founder of ODG Composites, traditional gel coats can account for 15-25% of the total part weight depending on part size. Element Xtreme, sprayed directly into the mold prior to infusion and cure, is said to save weight by up to 50% compared to gel coats. Less coating is required due to the hardness of Element Xtreme.

Available in a wide range of colors, the product has been developed for simple application, fast cure and a Class A finish directly from the mold. Element Xtreme is formulated to last, offering long-term protection in moderate to severe environments; resistance to fresh water, saltwater and many chemicals and fumes; and abrasion and moisture resistance.

Element Xtreme Coatings is said can be applied to any epoxy-infused composite parts in a variety of industrial and commercial end markets, with high utility in the marine industry including fishing kayaks and boat components.

For more information or to order, contact Emanis at (817)-386-0696 or russ@odgcomposites.com, or visit www.odgcomposites.com.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)