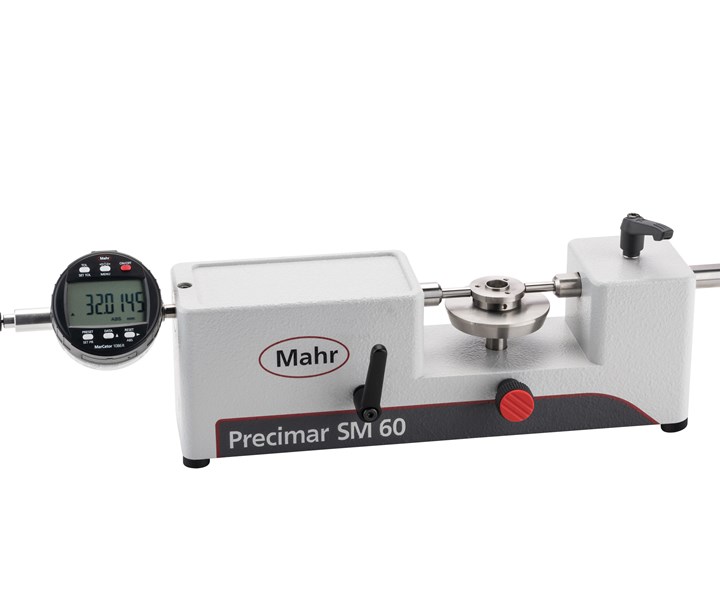

Mahr's Precimar SM 60 speeds length measurement

The SM 60 is a length measurement system with a measuring range of 60 mm, and is configurable with Mahr readouts such as digital indicators or LVDT probes.

Source | Mahr

Mahr Inc.’s (Providence, R.I., U.S.) Precimar SM 60 is a length measurement instrument designed for fast and precise external measurements on shop floor parts. The SM 60 is said to have a measuring range of 60 mm and to be configurable with Mahr readouts such as digital indicators or LVDT probes. It incorporates a 25-mm sensitive contact and a fixed reference jaw with a 35-mm adjustment to obtain its full 60-mm measurement capacity.

According to the company, the SM 60 is designed for high-performance gaging at the point of manufacture, and is easily adaptable for new workpieces, enabling the system to act either as a long-range measuring system or as a high-performance comparator for sub-micron applications.

The user selects the preferred readout for level of performance and application of the measurement. For applications requiring versatility, a 25-mm MarCator 1086 or 1087 is available, featuring a large display or analog dial. If higher resolution and performance are required, a Millimar P2004 LVDT with ±2-mm range and C1200 bench amplifier are available to provide sub-micron performance at the machining process.

The SM 60 also features integrated coupling to protect against over-range damage, hardened contact surfaces on both the sensitive and reference contacts, and an easy-to-adjust support table and optional floating micro-center support. For increased versatility, a family of measuring attachments for the standard contacts is available, including contacts with radius surfaces, flat-edge contacts and flat contacts with various diameters, allowing for plain OD checks for adding gage pin wires, OD thread checking and a threaded contact set for adding any of Mahr’s standard M 2,5 threaded contacts.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)