Portable Hexagon Leica ATS800 achieves rapid measurement of large, intricate components

The Leica Absolute Tracker delivers accurate measurement of key features from a distance, using direct scanning to meet the demands of inspection and alignment in aerospace and other large-scale manufacturing sectors.

Hexagon’s Manufacturing Intelligence division (Hexagon, Stockholm, Sweden) introduces the Leica Absolute Tracker ATS800, which combines laser tracking with laser radar functionality to bring traditional reflector-tracking accuracy to noncontact measurement of large, fiber-reinforced polymer (FRP) parts. This means that it is sufficient to perform detailed feature and edge inspections and meet tight assembly tolerances from 10s of meters away, minimizing production bottlenecks on the shop floor.

The technological development enables manufacturers to accurately measure fine edges and features across large volumes. Whether for large aerospace or automotive structures, ship sections or wind turbine components, when using the ATS800 Hexagon says there is no need for operators or robots to be in close proximity to the part being measured. This avoids unreliable measurements and safety issues.

By combining direct scanning and reflector tracking capabilities, the system replaces two pieces of hardware with a single device. The ATS800 uses Hexagon’s PowerLock technology to automatically and immediately “lock on” to a reflector and tracks its movements in real time, providing an absolute reference. The ability to measure target reflectors also greatly simplifies robotic automation processes, by enabling precise positional referencing within a wider coordinate system when mounting the tracker on a linear rail or an autonomous mobile robot (AMR).

For example, an aircraft fuselage can be quickly inspected alongside production without bringing target reflectors to the part, reducing total inspection time from hours to minutes. Using multiple devices or an AMR, several fuselage sections or panels can be batch inspected overnight, further reducing inspection time and avoiding disruption during shifts.

Guided assembly processes use up-to-date digital measurements during 3D assembly and mating operations, and the ATS800’s simultaneous tracking capability provides metrology-grade guidance accuracy to help experts align and troubleshoot issues without stopping to recalibrate and remeasure.

Moreover, accurate, high-speed measurement of holes, fastenings and edges can keep up with high-volume automotive production — automatically inspecting critical features within seconds without interruption or the risk of robot collision.

The system can also reliably measure inaccessible features, such as the holes that make up the bolt pattern for the alignment and fastening of huge wind power sections, or similar industrial or construction pipework.

“Complementing our laser scanning systems, the highly portable ATS800 can cut manual processes from hours to minutes and support the generation of a digital twin,” Andreas Werner, CTO at Hexagon's Manufacturing Intelligence division, says. “Moreover, it can be used on our customers’ preferred AMR or robot systems to fast-track ‘push button’ automated inspection with confidence across the shop floor.”

The ATS800 is highly portable, IP54 rated and can be operated completely wirelessly, integrating all systems and electronics into a single lightweight tracker unit plus small control box that can be securely mounted to and integrated with common robotics control systems.

The technology is based on Hexagon’s established platform of Absolute Trackers. Customers will be able to interchange accessories like batteries, tripods and reflectors as required across their existing install base as their needs change. Designed to plug into customer’s existing workflows, the device supports Hexagon’s comprehensive software development kits, providing open support for integration within third-party manual and automated solutions.

The Leica Absolute Tracker ATS800 will be available to all customers in 2025.

Read Next

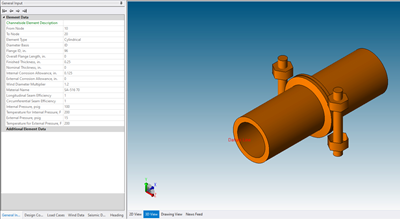

Hexagon unveils PV Elite 26 updates for pressure vessel design, analysis

Comprehensive software now comes with enhanced workflows, codes and connections for pressure vessel design, evaluation and analysis.

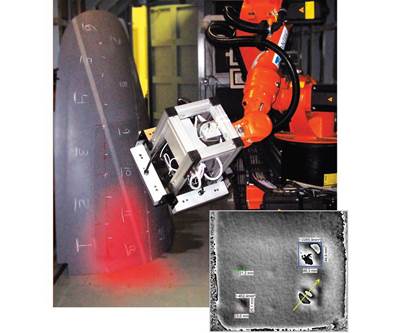

Read MoreAutomating NDT for CFRP aerostructures

Robotic laser shearography enables 100% inspection of complex, flight-critical composite structures.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)