Research center highlights sustainability, digitization technological offerings

JEC World 2024: Spanish research center Ideko showcases its knowledge, capabilities and experience in advanced manufacturing processes for composites to reduce the environmental footprint of aerospace production.

This year, Spanish research center Ideko (Elgoibar) is exhibiting its capabilities and technological innovations for composites manufacturing based on sustainability and digitization, with a primary focus on automating and increasing the efficiency of aerospace production.

Ideko’s exhibition in the Spain Pavilion highlights the expertise acquired in different European-scale research projects, showcasing the implementation of advanced composites manufacturing processes that have all been carried out within Ideko’s facilities.

One notable example is the INFINITE initiative, funded by the European Union, in which Ideko leads a technological consortium that seeks to develop digitally sensorized aerospace composites to monitor the manufacturing of components and their structural health throughout their lifecycle.

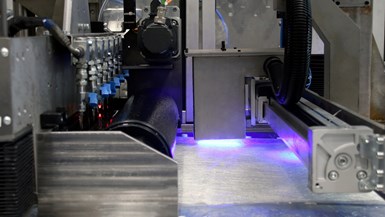

Additionally, INFINITE will offer a complete manufacturing solution based on photopolymerization, also known as ultraviolet (UV) curing, as an alternative to develop circular and efficient composite material manufacturing technologies through the results obtained so far in the research project.

Ideko’s expertise in this field will also be evident in its advances in the synthesis of a novel thermoplastic resin processable via a liquid phase, as well as the development of fuselage panels for the new regional hybrid-electric aircraft of the European Clean Aviation initiative.

The research center’s highlighted innovations also include research in robotics and automation technologies aimed at reducing emissions and the environmental footprint of manufacturing composite materials in the aerospace sector. Moreover, attendees can see and learn more about the development of a flexible, markerless positioning system using photogrammetry integrated into collaborative robots and compensated with external artificial vision systems.

To carry out the developments that are presented at JEC World, the Basque technological center maintains state-of-the-art facilities and several pilot cells. These include an automated dry material placement (ADMP) manufacturing cell, tailored for aeronautical components production, a fiberglass part manufacturing cell using UV-cured prepreg materials and a robotic cell — composed of two robots equipped with a photogrammetry-based positioning system, they work synchronously in the assembly of large aerospace parts.

Ideko houses multiple laboratories equipped with sensorization technologies for both process and product characterization. It also collaborates with several universities in the Basque Country to enhance its technological offerings.

Visit Ideko at the Spain Pavilion at Booth 108, in Hall 6.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.