Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

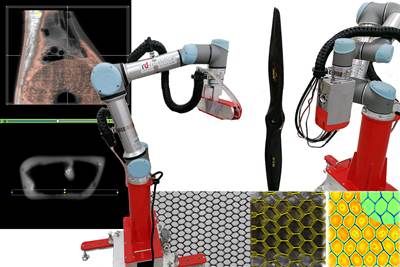

The Accubot is an advanced nondestructive testing (NDT) technology that leverages the latest developments in robotics, intelligent software and process optimization to offer high measurement freedom for composite structures. Source | Fill

Highly engineered materials like carbon fiber-reinforced polymer (CFRP) composites are preferred in aerospace applications for their exceptional strength-to-weight ratio, thermal stability and durability. Composites use here has surged due to the need for fuel-efficient and lightweight aircraft that produce fewer emissions. At the same time, these materials and processes have advanced to enable faster production of more complex structures — fast-curing resin systems, short-cycle thermoplastics, automated material placement and molding systems are increasing enabling integrated, unique geometry structures without fasteners or bonding. Composites 4.0 systems have also matured, facilitating data exchange during digitized, high-rate manufacturing.

Ensuring the integrity of composite structures for aerospace applications requires meticulous design, manufacturing and inspection thorough enough to detect any flaws that could propagate under extreme operating conditions. Nondestructive testing (NDT) is thus an essential technology, comprising a variety of analysis techniques to evaluate the properties of a material, component or assembly without affecting its usability (see “Non-destructive inspection methods available to composites manufacturers”).

With certifications such as AS9100, Nadcap, ISO 14001 and 45001, and partnerships with global aerospace OEMs — Hindustan Aeronautics Ltd. (HAL, Bangalore, India) and the Indian Space Research Organization (ISRO, Bengaluru) — aerostructures fabricator Kineco Kaman Composites India (KKCI, Goa, India) has established its credentials in the industry and is integrating Industry 4.0 technology throughout its Goa facility. A vital part of that initiative is KKCI’s collaboration with machine engineering company Fill Gesellschaft (Gurten, Austria) to develop a bespoke system for automated NDT testing.

Challenges of composites NDT

KKCI in Goa, India, holds AS9100, Nadcap, ISO 14001 and 45001 certifications and partners with major global aerospace OEMs HAL and ISRO. Its Goa facility is integrating Industry 4.0 technology throughout. Source | KKCI

In the realm of NDT, parts made using composite materials present a unique set of challenges compared to traditional metals, largely due to their anisotropic nature — e.g., multiple fiber orientations in multiply laminates, ply buildups and drop-offs, various core materials in sandwich construction, etc. KKCI uses advanced composites in its aerospace applications, which range from 2D laminates to multifaceted 3D structures. These materials are typically made using CFRP prepreg and are designed using monolithic or sandwich layup methods with aluminum honeycomb and, on occasion, Nomex cores.

The company has produced the 10 dual helix antennas for the Indian Regional Navigational Satellite program (IRNSS), equipment bay shroud assemblies for the LVM3-M2/OneWeb India, ITSC closure plates, ITSC, LOX and LH2 wire tunnel and bottom plate assembly, and FSA casing composite elements for the Chandrayaan-3 mission LVM3-M4 launch vehicle. Most recently, it produced the orbital module adapter (OMA) assembly for the geosynchronous satellite launch vehicle (GSLV) Mk-III, a critical component for the ISRO’s human spaceflight mission, Gaganyaan.

KKCI was responsible for manufacturing several critical components for the Chandrayaan-3 mission LVM3-M4 launch vehicle. This included the equipment bay shroud assembly, ITSC closure plates, ITSC, LOX and LH2 wire tunnel and bottom plate assembly. Additionally, KKCI also fabricated the FSA casings composite elements. Source | KKCI

The structures mentioned here are exposed to severe conditions during launch and re-entry, such as mechanical strains, atmospheric chemical corrosion, high levels of radiation and extreme temperatures at high altitudes and in the outer atmosphere. The manufacturing process for these composites requires precision and accuracy at every step, starting from the initial production stages to the final delivery, to ensure the best possible quality and performance. These requirements necessitate specialized adaptations for traditional NDT methods such as ultrasonic testing, thermography and radiography in order to detect foreign object debris (FOD), delamination, fiber misalignment and matrix cracking, among other typical composite material flaws.

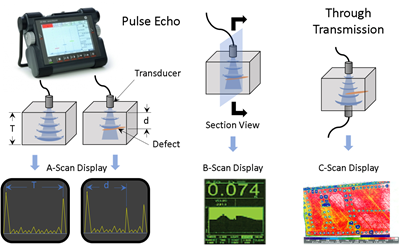

Ultrasonic testing (UT) using through transmission (TTU), or pulse echo (PE) techniques is the most widespread NDT method for the inspection of aerospace composites. These employ high-frequency ultrasonic sound waves passed through the component, which is typically sprayed with water to act as a coupling medium for the sound waves. TTU employs two transducers placed on opposite sides of the material being tested. One of the transducers creates a pulse, and the other receives it. Disruptions in the pulse indicate a defect is present in the path between the two transducers. PE uses one or more transducers to emit, pulse and monitor the reflected waves or echoes. As with TTU, data is captured, logged and analyzed to identify, locate and measure defects.

The need for 4.0 technology

“KKCI sees the increasing demand for composite aerospace structures and the need for high-precision fabrication and consistency,” says Shekhar Sardessai, chairman and managing director of KKCI. “Our strategic focus on Industry 4.0 principles, such as automation and smart integration, is aligned with our long-standing position of preparedness for the future. In order to pursue the type of programs we are interested in across the aerospace, defense and space segments, KKCI recognizes the importance of improving and automating our NDT capabilities.”

KKCI boasts a wealth of experience and expertise in high-performance composites, garnered through its participation in numerous space projects that demand the highest standards. Here, KKCI composite components are shown on the IRNSS navigation satellite. Source | KKCI

The operations manager at KKCI, Swapnil Mane, emphasizes that it is crucial to have robust NDT capabilities that can detect all surface and sub-surface discrepancies accurately. “Various factors such as foreign matter inclusions, delamination or porosity can lead to the development of internal discrepancies,” he says. “These discrepancies can propagate under extreme conditions, potentially compromising the required specifications of aerospace composite materials. To avoid such scenarios, KKCI needed to improve its NDT analysis techniques to evaluate the properties of their composite components and systems more accurately.”

To meet these requirements, KKCI collaborated with Fill, an advanced automated systems engineering company that designs and implements automated systems for a variety of industries, including composites. The result was a bespoke version of the DRS Accubot system for automated NDT testing. “Automated NDT technology for this industry requires precise and rigid robotically controlled kinematics to guide the corresponding end-of-arm tool [EOAT] along the part’s complex curved edges and surfaces,” explains Thomas Gramberger, who works in Fill’s aerospace manufacturing systems project engineering and sales. “Standard industrial robots are not designed to meet these requirements, so we decided to develop our own product called the Accubot.”

KKCI specifically opted for a waterjet TTU Accubot system. “Waterjet TTU is the foundation for 80% of Fill’s inspection systems,” says Gramberger. “This indicates its effectiveness in aerospace applications.” Fill had already developed such a system for GKN Aerospace’s (Redditch, U.K.) plant in Munich, Germany, which enabled a significant increase in its NDT productivity and reliability (see “Fill Accubot spurs GKN Aerospace composite aircraft parts inspection”).

Accubot design

KKCI’s Accubot system is equipped with two articulated robots that function on linear axes. Measuring 7 meters long, 2.5 meters wide and 4 meters high, it offers a combined 16 axes, including two independent electrically clamped servomotors that drive the linear rail. The dual robots can work independently or in coordination, providing a wide range of operations. This inspection system is specially designed for waterjet A-Scan and C-Scan inspections and can operate at a speed of 2,000 millimeters/second thanks to its pulse repetition frequency of 4 kilohertz.

KKCI’s Accubot system, which is equipped with 16 axes driven by two independent electrically clamped servomotors that drive the linear rail, measures 7 meters long, 2.5 meters wide and 4 meters high, allowing it to inspect large aerospace structures. Source | KKCI

“Accubot leverages the latest developments in robotics, intelligent software and process optimization to offer high measurement freedom for composite structures,” says Gramberger. The system employs dual six-axis Stäubli (Pfäffikon, Switzerland) TX200L robot kinematics integrated with the Siemens (Munich, Germany) Sinumerik CNC controller for its operations. Additionally, Fill has installed secondary rotary encoders on the robot’s rotary axes to ensure consistently high precision — Accubot boasts an absolute positioning accuracy of <0.3 millimeters.

It does this, explains Gramberger, by using a combination of the secondary encoders and a sophisticated compensation technique based on high-order kinematic modeling that calculates the real-time interpolation cycle of the controller. This setup enables real-time position compensation capability, anchored by an additional calibration system using a laser tracker.

An additional servomotor-actuated appendage is fitted at the end of each robot arm, fully integrated into the robot’s kinematic chain. Effectively serving as a smaller, more agile finger, this “active tool” is designed to facilitate comprehensive scans of small cavities, complex geometry parts and contoured narrow angles in tight spaces where it is difficult for the standard robot to reach without collisions, thereby significantly increasing the envelope of operation for the system. Additionally, the Accubot system can be configured for 2D or 3D inspection techniques.

This “active tool” functions as a smaller and more agile finger, enabling thorough scans of intricate parts with complex geometry, narrow angles and small cavities in tight spaces where standard robots would typically collide. As a result, the system’s operational envelope is significantly expanded. Source | Fill

Dual frequency, digital twins and reporting

The Accubot’s control electronics are supplied by Force Technology (Brøndby, Denmark). The device incorporates eight ultrasonic channels based on the company’s Force-P-Scan PSP-5 software. It equips the Accubot with the ability to perform dual-frequency inspections, allowing it to operate at 1 megahertz with a resolution of up to 120 decibels and at 5 megahertz with a resolution of up to 115 decibels simultaneously during a single scan. This makes it highly versatile in handling materials with varying densities.

The Fill Studio software environment manages automated scanning using specialized path-planning algorithms. It can communicate with various factory-level systems based on widely used MQTT, OPC and UA standards for Industry 4.0. The software includes a digital twin of the entire system, which supports offline programming of the robots during machine operation and provides an augmented reality interface. The digital twin ensures maximum machine utilization by performing cycle time analysis and collision avoidance while the inspection is running.

KKCI has chosen to use an Accubot system for waterjet TTU, an NDT technique that is commonly used for inspecting aerospace composites. Source | KKCI

The process flow entails training the Accubot system to identify the part within the work cell. This is followed by offline programming (OLP) using part CAD files. Next, the OLP program is loaded into Fill Studio, and the necessary UT parameter settings are configured in P-Scan to generate the final recipe for part inspection. Additionally, each robot can perform a separate, independent task and then be integrated to carry out subsequent TTU inspections working in harmony. The Fill Studio automatically coordinates the resources between each robot, enabling one robot to start its automated cooperating job as soon as another robot has completed its task.

Once the TTU inspection is completed, the data is forwarded to the evaluation phase where Fill’s technical partner, Testia (Toulouse, France), employs its NDTkit UT software for evaluation and reporting. NDTkit UT is fully compliant with Airbus requirements and offers porosity evaluation and SNR (signal to noise) calculation and threshold determination as defined per Boeing standard BAC 5980.

Improved NDT efficiency, productivity at KKCI

The Fill Accubot system at KKCI has advanced the company’s inspection capability and significantly reduced overall component production cycle time since its installation in early 2023. KKCI reports it has contributed to a 20% improvement in production efficiency when compared to previous production and evaluation methodologies.

KKCI conducted a trial of the Accubot NDT system for a space mission program commission. The testing was performed on the OMA assembly for the GSLV Mk-III for the Vikram Sarabhai Space Centre (VSSC) Gaganyaan project in collaboration with ISRO. The system was used to validate the 4-meter-diameter conical CFRP sandwich structure, which was integrated with machined metallic rings to tight tolerances. The OMA assembly plays a vital role in the Mk-III, acting as an adapter between the crew escape module and equipment bay shroud.

The Mk-III spacecraft comprises several components, including the OMA shown here, which is one of the most critical parts connecting the crew escape module with the equipment bay shroud. Source | KKCI

“Before the implementation of Accubot, inspections similar to the ones we did with VSSC took over 40 hours, while with Accubot, the inspection time was reduced to approximately 7 hours,” says Sardessai. “This efficiency enhancement is a testament to the system’s effectiveness in streamlining aerospace composite inspections. This system not only improved time efficiency and accuracy but did so with minimal human intervention.”

The Accubot system installed at KKCI features a modular design, enabling KKCI to incorporate additional inspection modalities in the future, such as laser-excited acoustic inspection and thermography, without extensive modifications. According to Sardessai, KKCI has some significant projects in the pipeline that could indeed demand this capability, further reinforcing the value of investing in this system. The Accubot system’s efficiency gain aligns with KKCI’s plans to facilitate more Tier 1 and OEM composite structures manufacturing in the near future and implement ISO 45001.

Gramberger concludes, “The integration of Accubot C-scan and A-scan data in the production process of composite aerospace structures is an effective measure for improving part quality, traceability, efficiency and data-driven decision-making. Because the Accubot system is so precise and it can be adapted to various inspection types, it’s now integral to KKCI's nondestructive testing future. It means more accuracy and adaptability for their programs while ensuring the safety and integrity of their composite components.”

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreRead Next

CW Top Shops 2023: Honoring global top-performing facilities

CW congratulates the 2023 CW Top Shops honorees and composites fabricators whose leaders cite team expansion, focus on Industry 4.0 and adaptation to emerging markets among this year’s top achievements.

Read MoreNondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

Read More