Robotmaster V7 offers CAD/CAM integration

Hypertherm has launched Robotmaster V7, a task-based robot programming platform rebuilt on new architecture to offer integrated CAD/CAM functionality and more intuitive robot programming tools.

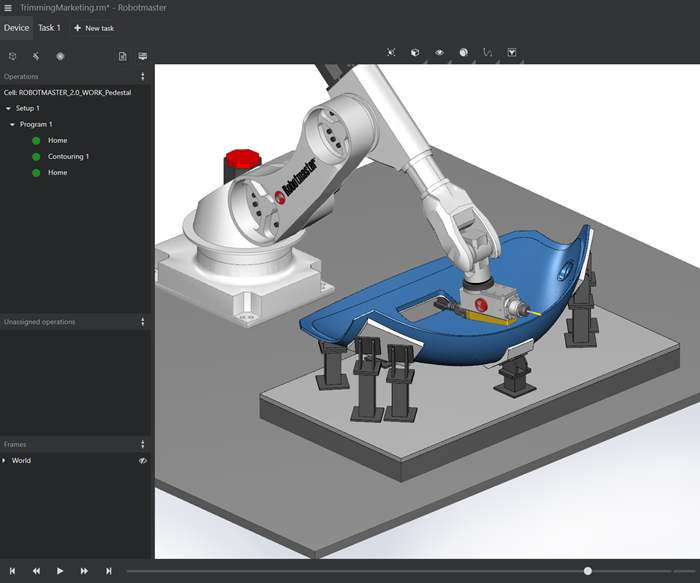

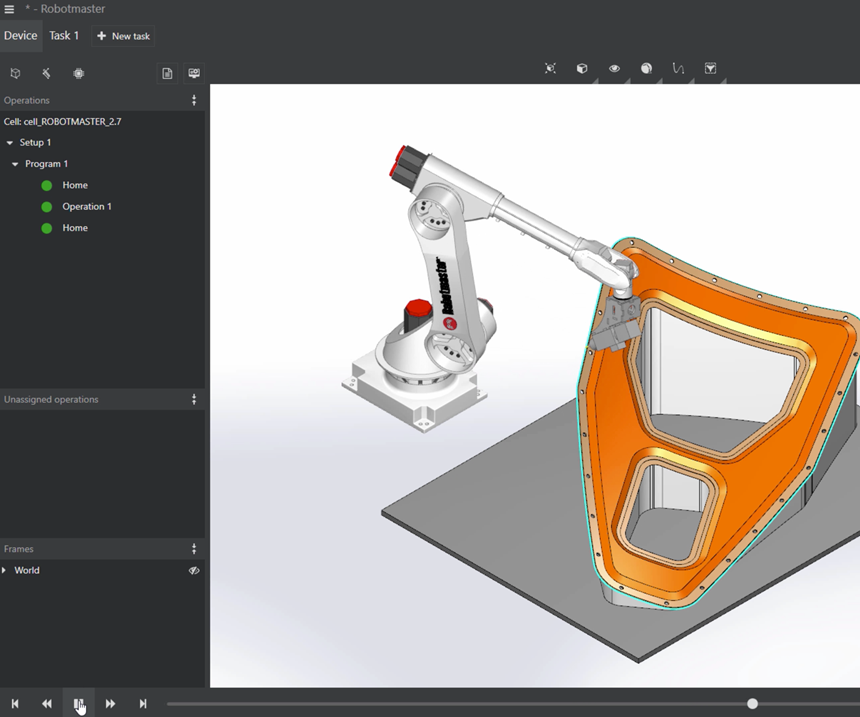

Hypertherm (St. Laurent, Quebec) has launched Robotmaster V7, a task-based robot programming platform rebuilt on new architecture to offer integrated CAD/CAM functionality and more intuitive robot programming tools. The new Robotmaster V7 software targets automatic, integrated welding and contour programming including trimming, cutting, dispensing and deburring, as well as drilling and fastening. It navigates complex part geometries and optimizes robot paths while synchronizing movements and reportedly preventing collisions between one or more robots, parts and tooling.

Chahe Bakmazjian, Hypertherm head of strategy, robotic software, says Hypertherm sought, with the new Robotmaster, to address specific challenges associated with automated trimming, drilling and inspecting of composite parts and structures, particularly in aerospace manufacturing environments. The feature most in demand, he says, was the ability to close the loop between composite part design and composite part finishing operations. As a result, Robotmaster now includes a bi-directional software bridge to receive data from and send data to CAD programs. Such data interchange allows Robotmaster to assess the part design, compare it to the robot programming, and check for overall machine-ability. The software then can generate programming pass/fail signals, collision risk assessments and kinematic data regarding robot reach and work point conditioning.

Robotmaster V7 can be used for offline robotic programming in a variety of industries including aerospace, automotive, consumer electronics, power generation/energy and welding. Subsequent modules enable additional tasks, including surfacing, 3D milling, additive manufacturing and inspection. Future editions will incorporate specialized task sharing tools for multi-robot workcells and Industry 4.0 capability, enabling the Smart Factory.

Related Content

-

Swedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

.jpg;maxWidth=300;quality=90)