The first demonstrator project for the PlasticRoad (now CirculinQ B.V.) concept involved installation of 30 meters of bike/footpath in the Dutch city of Zwolle, which helped solve that municipality’s challenges with recurrent flooding. Several other demonstrator bike/footpath segments have subsequently been installed in the Netherlands and Mexico. Commercial technology is now starting to be deployed. Photo Credit, all images (including image in line with title): CirculinQ B.V.

From London, U.K. bridges requiring foil wrap during record-shattering European heat waves, to millions of residents in Bangladesh and Pakistan being flooded out of their homes to landslides in multiple regions that destroyed roads and wiped out entire villages, recent news has been full of stories about how extreme weather is taking its toll on infrastructure in many parts of the world. In response to the ravages of climate change, governments and non-governmental organizations (NGOs) are increasingly exploring the development of technologies to “harden” roads, bridges and other critical infrastructure against damage.

Extreme weather in many parts of the world is overwhelming civil infrastructure. Severe storms and heavy rainfall cause issues in urban environments due to large amounts of impervious surface — concrete or asphalt roadways and sidewalks, plus large numbers of buildings designed to shed water, not collect and infiltrate it. When rainwater cannot absorb into the surface on which it falls — as it does in natural areas like fields, forests and lakes — it tends to collect and flow (via gravity) to lower-lying areas. The rapidly increasing volume of water and speed of travel during heavy rain can quickly overwhelm storm sewers, leading to catastrophic flooding, sewage release and erosion.

Forward-looking urban planners are turning to a variety of technologies to better handle severe stormwater events in urban and suburban settings by creating opportunities to collect and infiltrate water locally. Among these technologies are pervious concrete, which features holes that enable rainwater to travel into subsoils; living roofs, which are planted with succulent plants that absorb significant rainwater and store it in leaves and stems; rain gardens, meant to temporarily collect and hold water for one to two days, then slowly release it into soil; and roof-mounted cisterns that collect and filter water for local use.

CirculinQ (formerly PlasticRoad) is another technology that collects and slowly releases heavy rainfall back into local soils or storm sewers, enabling the initial heavy flush of water to pass while helping to avoid overwhelming local infrastructure. The durable, modular paving system features snap-fit modules comprising a tri-layer sandwich construction that is injection molded from glass fiber-reinforced post-consumer recycled (PCR) polypropylene (GR/PP). The system temporarily stores stormwater runoff and infiltrates excess rainwater into local subsoils, helping reduce flooding risks while recharging local aquifers in urban environments.

The CirculinQ system, which is called CCL (for circular, climate-adaptive, lightweight), is targeted for footpaths, bike paths, parking spaces, pavement, platforms/public squares and school playgrounds. Several Dutch demonstrator projects and one Mexican project have already proven the benefits of the system under different environmental and soil conditions. Commercial technology is now being deployed.

Iterative design

Initial concepts for what was then called the PlasticRoad were developed in 2013 at KWS Infra B.V. (Vianen), the Netherlands’ largest road builder. To validate the concept, in 2014 KWS — which is part of Koninklijke VolkerWessels B.V., a major European construction services business in Amersfoort, Netherlands — conducted a feasibility study with potential clients that yielded a wish list of features to incorporate into evolving concepts. In 2015, the concept launched to overwhelming public interest and international media coverage. Development partners were sought and found in Wavin B.V. (Zwolle, Netherlands), a manufacturer of plastic pipe primarily used for drainage and water supply, and work to refine the concepts began.

The team shifted to engineering and prototyping in 2016. An early prototype was installed at a KWS site in Utrecht, Netherlands, followed by extensive field testing and on-site monitoring — the latter powered by a collaboration with visual sensing platform/smart sensor supplier Zensors Inc. (San Francisco, Calif., U.S.). Additionally, Total SA (Courbevoie, France) came onboard as the project’s PCR plastic supplier.

Meanwhile, the team explored which polymers were best suited for the modular paving units. By 2018, the first trials for the paving system began when 30-meter sections of bike/footpaths were installed in Zwolle and Giethoorn, Netherlands. During this period, the team also explored multiple snap-fit connector designs to enable quick connection/disconnection of components in individual sections and between sections of the modular paving system as well as options for rainwater spillway systems. This led to further optimization of paving unit design and installation.

Intensive monitoring of the trial sections of PlasticRoad were the focus in 2019. Sensor data was collected and analyzed and insights gained led to additional design modifications. The team also explored whether the system could be used for parking lots. By 2020, PlasticRoad B.V. — a 50/50 joint venture between VolkerWessels and Wavin — was founded, tools to mold system components were commissioned and buildout commenced for the Hardenberg production facility and Vianen office. Additional design changes were made as the system neared commercialization. In 2022, the company readied for industrial scale manufacturing for the Dutch market. In 2023, PlasticRoad became CirculinQ.

Tri-layer construction

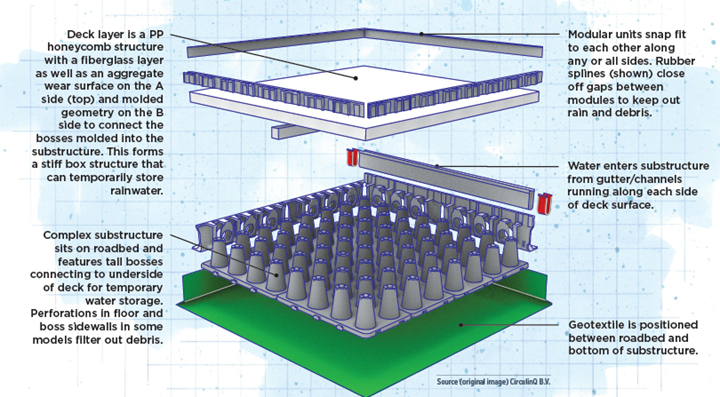

Appropriate for either redevelopment or new construction, the CirculinQ modular paving system has a tri-layer construction: the substructure holds and infiltrates water into soils while permitting cabling and other services to run through; the honeycomb PP/fiberglass deck snap-fits to tall bosses (that increase stiffness/strength) molded into the substructure and hatches on some models facilitate cleaning (top); the wear surface, a thin layer of aggregate on top of the deck, increases grip.

As designed, modular paving segments are 2,455 millimeters long × 405 millimeters tall/thick and are offered in multiple widths: 1,210, 1,810, 2,410, 3,010 and 3,610 millimeters. Module mass is <43 kilograms/square meter, yet it can hold axle loads of 5 tonnes and offers gross/net rainwater buffer volumes of 300/286 liters/square meter.

Units can be joined via snap-fits along all four sides; rubber splines/gaskets seal gaps between connected modules. Individual components or complete modules can be disconnected and replaced at any point.

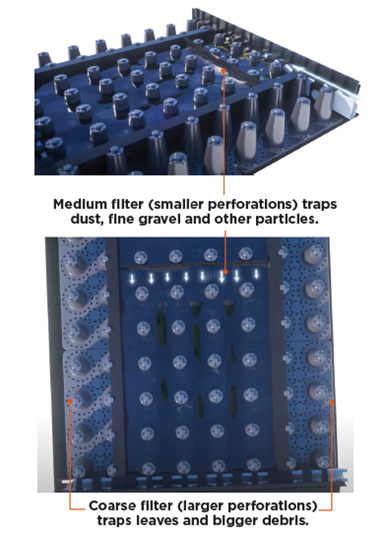

Modules feature a three-layer construction of substructure, deck and wear surface. All are injection molded from recycled GR/PP and feature a 30-year life expectancy. The complex substructure sits on the roadbed. It temporarily stores rainwater prior to infiltration or release to storm sewers. (Some models also filter water via a series of coarse and medium perforations on floor and sidewall surfaces.) Tall bosses on the B-side increase stiffness/strength and snap-fit the substructure to the underside of the deck.

The deck, a honeycomb PP/fiberglass structure, connects with substructure bosses, creating a stiff box structure with open sides. The wear surface, a thin aggregate layer applied on top of the deck, provides grip for tires and shoes even in wet weather (safety skid resistance (SRT) value >60). Options include Dutch crushed stone, red crushed stone, emery or calcinated bauxite (bonding values = 2.4 newtons/square millimeter), in colors of, red, dark gray or light gray, with or without line/lane markers.

Wear surfaces protect underlying components from weathering to prevent microplastic release. A 1-2-degree slope between each module’s center/crown and edges causes falling rain to flow to the sides where it drops into gutters and is fed into the water holding area in the substructure before. After that, water is slowly infiltrated into local soils or released to storm sewers.

A slight slope between crown and sides of each module causes rainwater to flow to the sides where it falls into gutters. Water initially moves into a coarse filter (lighter gray sections along left and right sides) and is forced through perforations in the floor and boss sidewalls, trapping leaves and larger debris. Next, water moves into the center of the module (darker blue) where it again is forced through smaller (medium) perforations in the floor and boss sidewalls. Water collects in the bottom of the substructure where it slowly infiltrates into soils by passing through the perforated bottom of the substructure and then through a geotextile that sits on the sand bed.

Three variants of CirculinQ’s system are initially offered. The premium CCL-300 model features integral stormwater filtering and drainage, enabling local authorities to eliminate connections to dedicated storm sewers via storm drains. These cleanable units collect and filter runoff, purifying it of dirt and plant material, before infiltrating water into local subsoils, recharging local aquifers. In addition to coarse and medium filtering through holes in the substructure, CCL-300 units also feature fine filters of flexible PP tubes wrapped with a recycled PP nonwoven and feature smart sensors that alert when filters need replacing. Annual maintenance on CCL-300 units involves using a street cleaner to vacuum up coarse debris along module sides. Every three to five years, gutters require flushing with a pressure washer. Every five to 10 years, ultrafine flexible filters are replaced. And the battery that powers smart sensors in filters is replaced every five years.

The non-cleanable CCL-200 model also features coarse filtering via holes in the substructure, but it does not offer fine filtering. This model is tied directly to local storm sewers via conventional pipes. During storms, units temporarily collect excess water and infiltrate it into local soils. Should the system’s storage capacity be exceeded before water can infiltrate, excess runoff is shunted to storm sewers with enough of a delay to help overloaded systems handle the influx.

A third option, CL-100, is a lightweight paving option without the ability to store water. Essentially, this model features the top/non-skid deck of the other systems in a curved/circular structure rather than rectangular shapes.

Circularity

While already green in construction (PCR plastics) and function (rainwater filtering and infiltration), CirculinQ intends for the system to eventually be zero waste and fully circular, with damaged components or entire units being removed and recycled/upcycled back into units for new installations. Reportedly, the system already provides longer service life, lower cost of ownership and reduced greenhouse gas emissions than concrete or asphalt. It also reduces plastic waste and better manages stormwater runoff during severe rain events

“While reinventing an infrastructure solution was daunting, it also was exciting,” recalls Jeroen Oudshoorn, CirculinQ managing director. “We asked ourselves ‘What if we could recycle single-use plastic into something so practical, valuable, sustainable and easy to install that it made cities more livable and lovable, while leveraging an existing resource (plastic waste) that causes so many problems?’ We carefully designed our CCL series products to be the most circular paving solution available today. They address complex, modern challenges related to plastic waste, urban water management and soil subsidence. You can use them to construct bike paths, footpaths, parking lots and squares. They are a comprehensive solution for flooding, erosion and subsidence of soft soils, plus they reduce harmful emissions by 72%, and are a sustainable alternative to incinerating, dumping or exporting plastic waste. When instrumented with sensors, they provide information on traffic and alert when maintenance is needed. They are a road plus a temporary water storage and drainage system — all rolled into a sustainable, climate-proof structure that perfectly addresses some of today’s most serious urban infrastructure challenges.”

Versus conventional paving, CirculinQ’s system checks all the boxes. It uses PCR plastics intended to be recycled again; functionally it helps infrastructure adapt to climate change; it offers lower cost of ownership and longer service life; 80% less energy is needed to transport units to construction sites where installation is 70% faster; and less heavy machinery is needed.

“Thanks to their long service life and modular format, CCL components offer much lower cost of ownership than conventional technology,” adds Marcel Jager, CirculinQ R&D manager and Wavin Group discovery manager T&I. “These lightweight, prefab elements are low maintenance. At 40 kilograms/square meter, they are the lightest paving structures in the world. It takes 80% less energy to transport them to a construction site — reducing total transport runs for a job — and requires less heavy machinery to install. With our snap [-fit] connectors, installation and replacement are as easy as using Lego bricks, so installation is up to 70% faster, greatly reducing nuisance delays. Throughout their use life they can be repeatedly detached for maintenance or repair, then reinstalled. And since they are produced from recycled materials, 75% less raw materials are used to produce them.”

He adds that modules can be placed directly on a minimized sand bed with no subbase needed, significantly reducing earthwork, cost and construction delays. Since subsoils are still accessible, it’s straightforward to run cables or pipes under paving surfaces. The units are well-suited for use in soft soil areas and, once installed, minimize further subsidence as well as aridification. “With integral water storage capacity of up to 300 liters/square meter, CCL paving can reduce the harmful effects of even extreme rainfall up to 100 millimeters/hour — and even in areas with high groundwater levels of up to 40 centimeters below grade, as we have here in Holland,” adds Jager.

Commercial rollout commenced in 2022. In the meantime, the company continues to refine and improve the technology and eventually hopes to expand its use to urban highways.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)