SGL Carbon offers customizable, prefabricated composite textile stacks

SGL aims to eliminate the work involved from material roll to stack for customers entirely, cost-effectively pre-cutting and assembling Sigratex stack packages to application specifications, saving time, cost and waste.

In an effort to make composite component production in serial manufacturing more efficient and more optimally integrated into existing industrial processes, SGL Carbon (Wiesbaden, Germany) is highlighting Sigratex stacks, precisely tailored and customer-specifically assembled packages of pre-cut carbon and glass fiber layers. Made of up to 15 layers of textile material, the stacks can be pressed into whatever shape is needed by the customers. Moreover, by cutting large numbers of parts from a single stack, SGL is able to optimize their shape and placement to minimize cutoff and waste, thus making the whole production more sustainable.

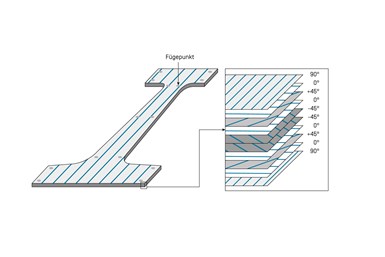

A “stack,” as the company describes it, is a textile structure for further processing in the process chain for manufacturing carbon fiber- or glass fiber-reinforced (CFRP/GFRP) components. The stack consists of different individual textile layers, which define the mechanical properties of the final component by material, number, orientation and grammage.

These individual layers are stacked, cut to size and joined together by different joining processes. Stacks are used as input material for the component-forming processes wet pressing and preforming/RTM.

While stacks themselves are not new — being the basis for almost all composite components manufactured — the rule is still that most component manufacturers purchase the carbon fibers as textile rolls and manufacture the stacks themselves. Alternatively, SGL’s solution eliminates this process entirely; the company takes over the entire textile process steps, such as fabric production, layering and cutting and supply the minimum necessary stacks for component production directly to the press. It also allows for the realization of larger geometries, enabling larger components to be produced from one piece.

The Sigratex stack service gives customers design freedom through textile selection, including fiber types, fiber orientations and basis weights. The company notes that its portfolio of textile reinforcement materials already covers numerous requirements of industrial applications — and what doesn’t yet fit can be adapted. SGL Carbon guarantees 100% inspection of the individual layers by online measurement of the textile top and bottom to avoid any potential defects during the process.

Related Content

-

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Cutting supplies, equipment enhance composites testing in the lab

CAMX 2024: On display at Extec’s booth is the Labcut 5000 precision composite plate saw, Nikon MA200 inverted metallurgical microscope and Labpol 12 automatic grinder/polisher.

.jpg;maxWidth=300;quality=90)