SGL Carbon achieves carbon fiber production with 50% reduced footprint

Eco-friendly carbon fiber slashes carbon footprint by half through renewable energy, a commitment echoed in SGL’s Lavradio biomass plant set to reduce CO2 emissions by 90,000 tons.

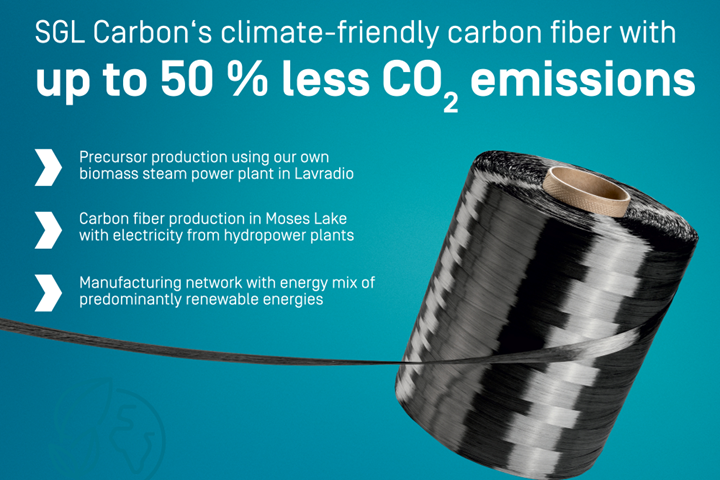

SGL Carbon (Wiesbaden, Germany) has announced the development of carbon fiber that relies on climate-friendly manufacturing processes. By using renewable energy during its production, the carbon footprint of SGL fiber can be reduced by up to 50% compared to a conventional fiber, according statistical data from the GaBi lifecycle assessment database. This means that sustainability is now a key characteristic of the company’s carbon fibers products, in addition to their high tensile strength and high stiffness with low weight.

SGL’s carbon fiber is produced at its Moses Lake (U.S.) site, and its precursor for the carbon fiber at a site in Lavradio (Portugal). The company says that it made a conscious decision to produce at the Moses Lake site back in the 1990s — the use of hydropower as an energy source played a decisive role in the choice of location. As a result, around 75,000 tonnes of CO2 can be saved in Moses Lake by purchasing electricity from hydropower plants compared to a fossil fuel-based electricity mix.

As part of the consistent implementation of its climate strategy, SGL Carbon will be using a CO2-neutral biomass system to generate energy from the beginning of 2024, which will make the production system, which was previously based on natural gas, more flexible and climate-friendly. At full capacity, the biomass system in Lavradio can reportedly save more than 90,000 tons of CO2.

The raw material used is wood pellets, which are sourced from within a radius of 250 kilometers. This means that SGL Carbon also attaches great importance to short transportation routes and thus to climate protection when sourcing biomass.

With the investment in the Lavradio biomass plant, SGL Carbon is targeting target saving 50% CO2 emissions (Scope 1 and 2) by the end of 2025 compared to the base year 2019, and to be climate-neutral in Scope 1 and 2 by the end of 2038. Between 2019-2022, SGL Carbon reports that it has already reduced its CO2 emissions by 17%.

Related Content

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.