Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

Custom fabrication, Tooling of Tomorrow (TOT). Airtech International’s newest location in Tennessee provides materials and custom vacuum bag fabrication for its growing customer base in the Southeast as well as its first U.S. location (TOT building, far right) for its 3D printing services, support and Dahltram resins. Photo Credit, all images: Airtech International

Airtech International (Huntington Beach, Calif., U.S.) was founded in 1973 by Bill Dahlgren with the goal of distributing materials for vacuum bagging and composite tooling to make glass and carbon fiber-reinforced composite parts for the aerospace industry. Airtech quickly grew into other industries, including motorsports, marine, wind and solar energy, automotive, armor, construction and space.

It also added facilities in the U.S., U.K., Luxembourg, China and now India, and expanded its products to become a “one-stop shop” offering a variety of vacuum bagging films — including very large widths and for ultra high-temperature cures — as well as release films, peel plies, breather and bleeder cloths, mold release liquids, pressure-sensitive tapes, vacuum bag sealant tapes, connectors and hoses, as well as an ever-expanding range of tooling materials and even carbon and glass fiber reinforcements.

Today, Airtech has more than 800 employees worldwide and is the largest privately owned manufacturer of vacuum bagging and composite tooling materials in the world. The company has also widened its scope of processes, moving beyond prepreg and autoclave cure to wet layup and out-of-autoclave (OOA) cure, including resin infusion.

Its new “Tooling of Tomorrow” (TOT) initiative aims to leverage Airtech’s expertise in extruding polymer films for vacuum bags and decades of experience in understanding and enabling composites manufacturing to address the needs of large-scale 3D-printed tooling — specifically with machines that are based on extruding thermoplastic materials — a technology that is growing quickly in the composites industry.

CW was invited to tour Airtech’s newest U.S. facility in Springfield, Tennessee. This 15,800-square-meter site provides an East Coast warehouse, additional manufacturing for Airtech custom-engineered products and a 4,700-square-meter space to accommodate TOT operations.

Room for growth, fuselage-sized vacuum bags

“In 2012, we started looking for a new facility in the U.S.,” says Jeff Dahlgren, CEO of Airtech Intl. “Our custom engineered products business was growing significantly and we didn’t have enough space in our California sites, nor room to expand our buildings there. We also needed a location closer to our growing customer base in the Southeast. This site in Springfield was not only centrally located for our markets, but already had a great building, was close to Nashville, had a good labor pool and, with 67 acres, plenty of room to expand. Our future growth will predominantly be here.”

Our tour was led by Dahlgren and plant manager James Wade. We entered the main production area inside the site’s main building — the TOT building is next door. This 9,000-square-meter space is mostly an open production hall. A large area in front of us was fenced off for traffic control. Here, technicians were working to convert a very large, welded vacuum bag into a customized kit for production of composite fuselage barrels for the Boeing 787 commercial jetliner.

“This large barrel bag will be cut into an arc shape, kitted with other materials and sent to the Boeing plant in Charleston,” says Wade. Barrel sections for the 787 fuselage — which can be 7 meters long (22 feet) and 6 meters wide (19 feet) — must be fully enclosed in such a vacuum bag before they can be cured in an autoclave.

“This is a turnkey solution, customized to save the manufacturer time,” says Dahlgren. “We cut it to size, add markings as specified by the customer and can include film, peel ply and breather materials. We do this for the 777X wing box, using a solid sheet of vacuum bag film that is 60 feet wide and 120 feet long, with 2-inch-tall pleats requiring 4,000 pieces of tape to hold the pleats in place. This bag meets ±0.25-inch placement tolerance over its length. We can produce it here and check it for quality so that it is ready to go out of the box. That bag gets delivered to Washington state for the wing production.”

“Pretty much everything we do here is custom engineered from our materials, which you will see there to the right in the incoming stock area,” notes Wade. “We are converting our vacuum bagging consumables into custom shapes for the specific needs of each customer, and we work with the customer to design the optimal vacuum bag for their application.”

This site, says Wade, has one of the world’s largest single matrix of laser projectors, used for aligning the patterns used to prepare these custom vacuum bags. “We have 15 laser projection heads, installed in the ceiling, that work together to share resources,” he adds. “We get the same precision every time and no FOD [foreign object debris], for example, with pieces of paper pattern left in. And when we want to make more of these products, we just add another laser projector.” He notes this system also aids customers when they change their parts. “We just update the CAD file and project the new pattern.”

“This is the end of the process,” says Wade, “where a lot of our kits come to be finished into larger assemblies.” He notes that the size of these custom bags and kits is growing as companies make larger components. “We’re seeing a need to support not only the 777X wing, but also the Falcon 9 payload fairing for SpaceX and parts for Blue Origin.”

These bags may be folded or rolled for shipping and ease of handling once received by the customer. “The engineering isn’t just in the kitting, but also in the packaging. These bags are very large and you don't want to manipulate them excessively. We work with the customer to design the storing and packaging to match how they want to deploy the vacuum bags in the application on their end.”

Benefits of customized bagging kits

Why would a company want to do this? “If they have high-turn items, very complex tooling or very complex parts where they don’t want to take the time in their operations to customize and shape the vacuum bag, we’ll produce that here and deliver it in a ready-to-go shape or combination they can use,” explains Dahlgren. “All of that work is done here, in a quality controlled process, so they can just focus on the operations to produce the actual parts.”

“These kits enable composite parts production with a lot less touch labor,” says Dahlgren. “It also eliminates the need for those companies to have a labor force skilled in how to cut and prepare these complex bags. They can simply start production with a bag that is ready to be used, and it’s the same bag every single time. You can take an almost unskilled laborer and make them a vacuum bagging technician a lot more quickly.”

“That labor savings and flexibility has helped our customers increase their productivity,” he continues. “They will pay more for the kits compared to just the vacuum bagging film — meaning more for the material per square foot — because it has more labor involved on our end. But it’s still a lot cheaper than their labor, and they can make parts more quickly and have less scrap bagging material. Here, we can take all that scrap and recycle it back into the films we make, so that’s an environmental advantage as well.”

Bespoke film welders and ply cutters

We walk left to a large table with a piece of equipment in the middle that is welding two wide bagging films together. “Although Airtech makes some of the widest high-temperature bagging films in the world, these aren’t wide enough for what we need in a lot of the custom kits we make,” says Dahlgren. “So, we designed and built this equipment for welding our vacuum bagging films together, which allows us to go as wide and as long as we need. We’ve made vacuum bags for yacht hulls that are 100 feet wide and 150 feet long and continuous bags that are upwards of 300 feet wide and 400 to 500 feet long. We’ve yet to find the limit for how wide we can go.”

“This machine lets us do everything in one operation, from roll to roll,” says Wade. “The bagging film comes off the roll, gets welded and goes back on the roll. We have a lot less handling of the bagging film — touching a very small section of film — while the rest of it is as produced, off the extruder. So, you’re getting very wide film in an unmolested form with higher quality.”

Figure 1. Custom bagging materials and fabrication. Airtech’s 7 × 52-meter XY ply cutter illustrates the size of high-temperature vacuum bagging films it can custom fabricate for composite structures such as the Boeing 777X wing and SpaceX Falcon 9 payload fairing.

The next station is Airtech’s XY ply cutters — with rotary cutters in X and Y directions to trim and slit flexible materials from rolls into sheets — again, bespoke machines, designed and built by Airtech.

“We’ve got a vacuum table for holding material down and gantry heads that can use a variety of cutting techniques depending on the material we’re using,” says Wade. “We can print markings specified by the customer using a standoff, no-contact inkjet printer with various print styles, such as silver or black Sharpie or silver pencil. These can be markings used for positioning indicators on their parts so that employees know where each bag needs to go.” The ply cutter in front of us is 7 meters wide × 52 meters long, with dual gantries to make use of that full cutting area. Further over is a 5 × 20-meter ply cutter that dates back to 2006 and is still used for smaller sheets.

Consistency in customized products

“One of the things that we’ve had to get really good at is training people swiftly,” notes Dahlgren. “Because we make so many different SKUs, everything we do is unique. We can’t train the entire workforce on every item. We have to have a way for them to quickly learn how to produce each customized item and what it’s supposed to look like. One of the solutions we’ve developed is a design for work instructions that makes them approachable and accessible so that employees can understand them.”

“We can get the same result on the production of each vacuum bag every single time,” says Wade. “All our work instructions are digital. The employees get a work order with a barcode, scan that barcode and it brings up the details for that work order. They can review the work instructions which include photos, videos and anything we need to describe how the employee should build that particular bag. They then combine those instructions with the CAD drawings to produce the wide variety of kits that we need to produce — from very large to small assemblies, from kits made twice a year to customized products made every single week in the hundreds or even thousands.”

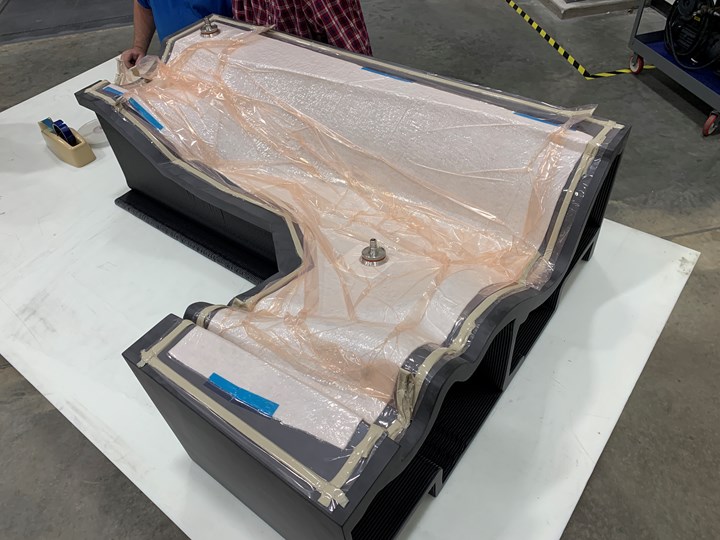

3D-shaped bags, warehouse

We walk through another welding area designed for bags with customized 3D shapes. These could be bags to produce a payload fairing for a spacecraft or a tight-tolerance part made on a mandrel. Machines here are also designed and built by Airtech. “Most off-the-shelf machines aren’t able to seal the vacuum bag to achieve good vacuum integrity,” says Dahlgren. “But we’ve designed our sealers specifically for high-temperature bagging film, which takes into account the nature of those materials.”

We then walk by a series of long, thin, blade-like parts. “Those are all for R&D,” says Wade. “We do tests to figure out how to make a specialized bag, for example odd-shaped bags that must fit to very tight tolerance so the customer can apply their process.”

We walk through a door to a large warehouse/shipping area with floor-to-ceiling racks filled with various products. “Our expansion in 2017 added this 50,000-square-foot warehouse,” says Dahlgren. “We’ve got over 4,000 pallet positions for storing raw materials, and we can ship out of here whatever products customers need.”

Tooling of tomorrow (TOT) building

As we enter the TOT building, Dahlgren notes it was built in 2020. Gregory Haye, director of additive manufacturing (AM) for Airtech, notes that operations began in January 2021. “For now, we have an LSAM [large-scale additive manufacturing] 1040 machine, sized 40 × 10 × 5 feet [length, width, height], from Thermwood [Dale, Ind., U.S.]. This same exact machine is also at our facility in Luxembourg.” He notes that many of the parts Airtech builds involve sensitive information from its customers, “so, we can’t show a lot of the great work we do, unfortunately.”

“We’ve been involved in tooling, almost from our beginning,” says Dahlgren, “mostly through tooling resins and prepregs. Then we started seeing 3D printing, and we really believe that it’s going to be the future for tooling. So, in 2018, we purchased this machine to develop better technology and produce better tools.” He notes that Airtech has been extruding thermoplastic vacuum bagging and release films for 50 years. “We know extruders as well as resins and flow engineering. And this LSAM machine is just a little extruder on a big gantry. So, even though it sounds like additive manufacturing is a complete departure from what we do, it’s actually right in our wheelhouse.”

The TOT team, led by Haye, was assembled from experts already established in the AM world, including some who worked in collaboration with Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) to install and commercialize its first machines. “And because our team was already experienced, we were pretty much producing from day one and we’ve been able to complete projects quickly,” says Haye. He notes one of those first projects was a structural spar mold tool for the space industry, filling a 2.5 × 5 × 1 meter envelope. “That was on our machine within the first two weeks of being commissioned. Next, we did a high-temperature autoclave tool.”

How are these 3D-printed tools different and what is their service life compared to conventional thermoset carbon fiber-reinforced polymer (CFRP) tools? “Our lead times are faster,” says Haye. “Depending on the size, we average two and a half to three weeks from completed design to tool completion. Using our Dahltram resins, we've printed tools that have completed more than 500 autoclave cycles at 350°F and can still hold ±0.005-inch tolerance, which is typical for tools used to mold aerospace composites.”

Figure 2. 3D-printed tooling and Dahltram resins. Airtech uses a Thermwood LSAM printer to produce tools and parts for customers (top) as part of its goal to support and expand 3D printing in composites. But it also aims to sell its compounded, pelletized Dahltram resins (bottom), which it formulates to provide high-quality prints in extrusion-based additive manufacturing machines, using its decades of experience in extruding thermoplastic vacuum bags and other films.

Dahltram resins

As Airtech started with the LSAM, it wasn’t very happy with the resins it purchased for printing. “We’ve been compounding resins ourselves for almost 50 years,” says Dahlgren. “So, we started looking at doing our own compound formulations.” This, it turns out, is the real goal. “Yes, we want to make tooling using additive manufacturing, but we’re not going to have 50 or 60 printers — our goal is to supply resins to everybody who buys these additive manufacturing systems.”

Airtech has customers that buy one or two tools on their way to buying their first 3D printing machine, says Dahlgren, “while others may use us as a service bureau for the next five years. We have a pretty diverse customer mix, but I think most will eventually buy at least one printing system. And we’re going to help these companies print the tools they need, and eventually, their whole range of parts as well.”

Dahltram printing materials are made from thermoplastic polymers reinforced with chopped carbon or glass fiber and compounded into pellets. They can be made using acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyethersulfone (PESU) or polyetherimide (PEI). “We have other resins that are coming to market soon, such as recycled PETG [polyethylene terephthalate glycol],” says Haye, pointing out a printed test specimen with a greenish tint made with this new Dahltram product. “We’re also looking at materials that, as tools, will be friendly to parts made with styrenated resin systems. This is typically a challenge for a lot of the current thermoplastic materials in the market.”

Dahltram products include five commercialized printing materials and two purging resin systems. “And we have validated those materials with the various machine OEMs, proving they can match our technical data sheets with their systems,” adds Haye. These 3D printing resins are not just focused on aerospace, but also developed for automotive, wind, construction and industrial applications. “We stock all our 3D print resins at all of our locations,” adds Haye. “And this also gives us a lead time advantage. It’s pretty common to hear lead times of 14-24 weeks, and we’ve made a commitment to beat that.”

Recycling requires the whole process chain

All Dahltram materials are designed to be recycled. “We have already done some preliminary work on this to show the properties that you can retain in different formulations,” says Haye. “We are working now to re-pelletize recyclate into new feedstock to establish a process for how to take the tools back, grind them and recycle that material into new feedstock. We’ve been saving our scrap here for the past three years, and now we’re pushing forward.”

However, Airtech has to make sure these materials can back into new products. “Each of our materials has a technical data sheet, and we’re not going to just sell something with random granulated materials from various sources,” says Haye. “We will verify the performance of these materials so you can design with it using our data sheets.”

“You can’t just grind up everything and print with it,” Haye continues. “For example, a large disparity in pellet size can create a choking point in the screw feed into the extruder, which can then cause inconsistencies and quality issues during printing. We take the recyclate back to a competent feedstock, which means re-compounding it into a pellet. This also means we can have materials that are machine agnostic.”

Airtech also recycles purged materials. Purging, which cleans the extruder, is part of Airtech’s cleaning process required for material changeovers as well as normal machine maintenance. “However, sometimes it’s required between printed layers in a tool,” says Haye. “For example, you may have a long dwell in the print process — and before it goes to the next layer, you need a small purging of the print material to make sure no material has been degraded because it has been sitting idle at high temperature for so long.”

“We collect that purged material, regrind it and then perform a series of compounding to reformat the materials,” says Dahlgren. “We also make our own cleaning purge pellets. We take an ecosystem approach to make sure the whole process chain works, and that makes recycling viable.”

Machining, vacuum integrity, tool design

We walk past half of a large 1.5 × 2.4 × 2.4-meter 3D-printed aircraft engine nacelle tool. “Its mirror half is in the LSAM being printed now,” notes Haye. “Both halves get bolted together and then we will perform finish machining.” He notes that almost every print is machined and 3D laser scanned to ensure the printed part’s accuracy per the STL model before it is machined.

Figure 3. Precision printing, machining and vacuum integrity. To ensure accuracy, Airtech 3D laser scans its 3D-printed parts before it machines them. Using Dahltram resins, Airtech 3D-printed tools have completed more than 500 autoclave cycles at 350°F while holding ±0.005-inch tolerance, typical for tools used to mold aerospace composites.

Even though the nacelle tool will be machined, it already has a fairly smooth surface. Airtech used a higher print resolution here than for the support structure, which is rough due to a larger print bead. “When we machine this tool, we’ll remove a nominal 0.25 inch of material from a 1.5-inch-thick printed facesheet,” says Haye. “The tool face uses two print beads because we know we’re going to machine a portion away, while the backup structure has only one bead because it doesn’t need machining.”

Does the printed tool surface thickness affect its vacuum integrity? Airtech tools have vacuum integrity, says Haye, not due to thickness, but due to the material and how it's processed. “We’ve demonstrated this on panels down to 0.25 inch thick as printed. When we first started, we printed two beads everywhere. But we’re learning more as we accumulate data and perform more design simulations. We’re also validating these simulations, performing thermal cycling of tools in-house. We’re always trying to make tools more efficient, in materials and/or design processes, but we step cautiously and always with validation.”

How are these tools and parts designed? “A customer typically gives us the digital design file for the part or the tool surface,” says Haye, “plus their list of requirements and the technical inputs we need. We then design the backup structure. Most customers have no experience with how to design for additive manufacturing, especially for large-scale tools. But we do. For example, we minimize contact at the back of the printed tool surface to minimize large heat sinks but also material usage. So, the tool is dimensionally stable, but also performs thermally as it should.”

“We’ve also developed annealing cycles to make these tools even more dimensionally stable,” adds Haye. “For example, we may add a heating process in between machining stages or after printing to reduce or relieve residual stress in order to maintain high surface accuracy. These tools will have a tolerance of ±0.005 inch.”

Validation, achieving aerospace quality

“All our materials are validated via as-printed samples,” says Haye. “We provide full mechanical evaluation and thermal characterization of the materials using as-printed panels and samples instead of the injection-molded dogbone specimens typical in the thermoplastics industry.” Airtech also validates the processing windows for its materials. “We log the temperature data from the extruder and correlate that with our printed sample testing so that we have a codeveloped extrusion profile with the machine manufacturers that says on this machine, these are the temperatures to use for the best results.”

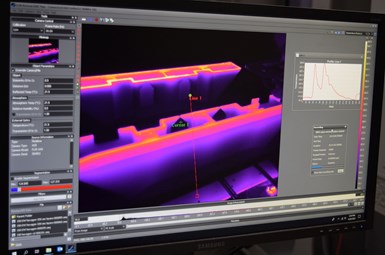

Figure 4. Validating process temperatures. Airtech uses two infrared cameras — one for the layer being printed, one for the surface below — to verify optimal printing parameters to ensure good adhesion between layers and high mechanical properties.

“We also give them the optimal layer temperature,” says Haye. “We measure the temperature at the interface between every single layer we print and the surface we’re printing onto.” This is done using two Flir (Teledyne Flir, Wilsonville, Ore., U.S.) thermal (infrared) cameras, one for the layer being printed and one for the surface below. “If the temperature at this interface isn’t warm enough, you won’t get good adhesion,” he explains. “We know that exact temperature, and there’s an optimal and safe range in there. But we also push the limits to see what happens if you go beyond the optimum and how does that affect the mechanical properties? We have that data for outlier scenarios, and we also look at the thermal gradients as the geometries change.”

“Our goal is to make this technology successful and foster its increased adoption,” says Haye. “So, we work with all of the extrusion-based 3D printing machine manufacturers, using a validation process where they print with our materials with our support to make sure they can process the materials properly. But this also results in parts that can meet stringent technical requirements. So, it doesn’t matter if the customer is printing on a robot printer by CEAD [Delft, Netherlands] or a large gantry machine, the results and performance, and even the CTE [coefficient of thermal expansion], is exactly as expected and as modeled in the part design and process engineering.”

This last statement sounds very much like an aerospace industry approach. “I do think it helps that we understand aerospace expectations,” he says. “We want to pull the whole market up that curve with us. Again, we’re chasing success which leads to increased adoption. It probably looks aggressive to some machine or parts manufacturers for us to say, ‘Hey, we need to do it this way.’ But we have the data to back it up and explain why.”

Dahlgren notes that Airtech supplied the resins that CEAD and GKN Aerospace Munich (Germany) used to print tooling for the serial production of CFRP flaps for the Airbus A350 (see “Adapting composites 3D printing to evolving needs”). “Many of our 3D-printed tool customers are companies that have been dealing with us for 50 years,” he says. “They know us and know that we will supply resins for 3D printing the way we have supplied tooling resins, prepregs and vacuum bags — to meet their needs and expected quality. And we now have this 3D printing equipment so that we can prove out our resins and do things that no one else wants to do, because we have a certain expertise. And we think we can use that to help expand the market.”

Adding machines, diversifying for the future

The Airtech TOT facility will add more machines based on supply and demand, says Haye, and to add new capabilities. “This LSAM machine offers a super large scale,” he notes, “but we will also have needs in the future for smaller scale systems. Our approach is to be equipment agnostic.”

Dahlgren adds that the TOT building has been designed with plenty of space to expand. “Already, we’re getting more calls to help the industry with printing and running their systems,” he says. “We’ve been successful with good quality resins that print really well. We know how to achieve the vacuum integrity and performance needed, and we can put our tools through the rigors of how the industry uses them.”

“I think this is part of what differentiates our team,” says Haye. “We have our global capability, technical staff, knowledge and resources. Not only do I count on that for supporting our in-house development, but we are also using it to support our customers. For example, we can say, ‘Here are all the requirements that this material or application needs to be able to do because we’ve been working with it for 50 years.’ We’re really fortunate that we have that knowledge base company wide, and we’re using that to help our customers and the industry.”

Indeed, Airtech’s leadership in the composites industry was recently acknowledged by the Society for Advanced Materials and Process Engineers (SAMPE), which recognized Bill Dahlgren, Airtech’s founder and the father of current CEO Jeff Dahlgren, one of CW’s tour guides, with the Mort Kushner Lifetime Achievement Award in 2022.

“We have this amazing, unique history,” says Dahlgren, “because we are a materials supplier, but we're also a subcontractor making customized kits for major OEMS and a lot of other companies, and then in the TOT building, we’re acting as a prime for key leaders in aircraft, space and other industries. We’re a little bit of everything, and you can see now the manufacturing side of what we do.”

“We have the third generation of our family coming up in this company,” he continues, “and I want to make sure we keep moving forward as technology does. Additive manufacturing is a key part of that future. This is an important diversification for our company. And the different resins we're going to come up with in the future and the different ways of printing will provide the next legacy for Airtech. But it's an extension of what we're already doing now. It’s a natural progression, which also happens to be the latest in technology.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreMetal AM advances in composite tooling, Part 1

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More