Solvay introduces high-temperature PEEK polymer

KetaSpire PEEK XT promises the chemical resistance of standard PEEK plus significantly higher strength and stiffness at elevated temperatures.

Source | Solvay

According to Solvay, (Alpharetta, Ga., U.S.) the company’s KetaSpire PEEK XT, introduced at the K 2019 trade show in Düsseldorf, Germany, is the industry’s first true high-temperature polyetheretherketone (PEEK). This material reportedly offers the chemical resistance of standard PEEK plus significantly higher strength and stiffness at elevated temperatures.

Compared to standard PEEK, KetaSpire PEEK XT is said to have a 20°C (36°F) higher glass transition temperature, at 170°C (338°F), and a 45°C (81°F) higher melting temperature, at 20°C (36°F). The material is said to exhibit significantly higher strength and stiffness at elevated temperatures compared to standard PEEK, with a 400% higher tensile modulus and nearly 50% higher tensile strength at 160°C (320°F).

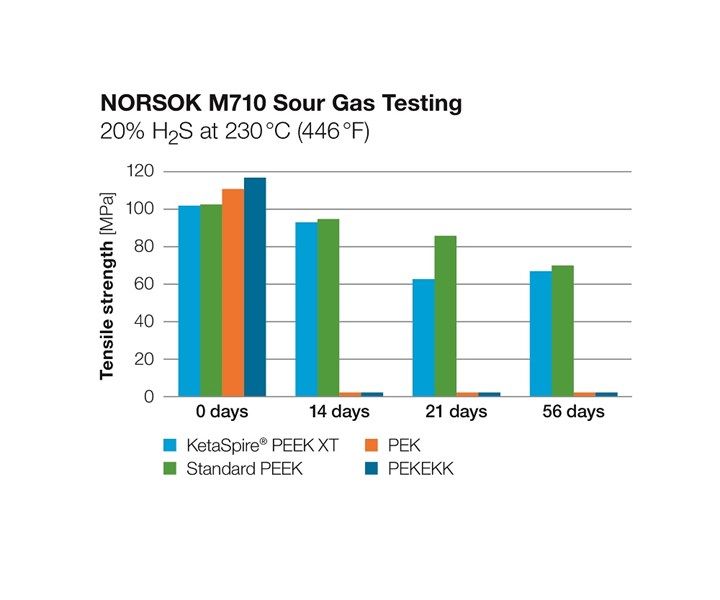

According to Solvay, other high-temperature polyketones, including polyetherketone (PEK), polyetherketoneketone (PEKK) and polyetherketone-etherketone-ketone (PEKEKK), alter the 2:1 ether-to-ketone ratio of a true PEEK polymer, losing some of PEEK’s chemical resistance. KetaSpire PEEK XT maintains this ratio, enabling it to superior chemical resistance to other high-termperature polyketones while exhibiting similar thermal properties.

In addition, KetaSpire PEEK XT is said to show superior electrical properties at 250°C (482°F) compared to standard PEEK, increasing dielectric strength by 50% and volume resistivity by an order of magnitude.

The material is available globally in neat, 30% glass fiber, and 30% carbon fiber-reinforced injection molding and extrusion grades, as well as in fine powder form for compression molding and as coarse powder for compounding. Applicable industries include oil & gas, electrical/electronics, wire coatings and automotive.

Related Content

-

UniSQ fire-retardant resins development bolster bushfire mitigation

The University of Southern Queensland has received funding to be used in the development of cost-effective composite resins to increase the resilience of wind turbine blades against bushfire exposure.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

.jpg;width=70;height=70;mode=crop)